Crystallization method and crystallization apparatus

a crystallization apparatus and crystallization method technology, applied in the direction of photomechanical apparatus, polycrystalline material growth, instruments, etc., can solve the problems of inability to exhaust all gas, inability to completely remove impurities and air bubbles that mix into grown single crystals, and greatly deteriorated optical performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

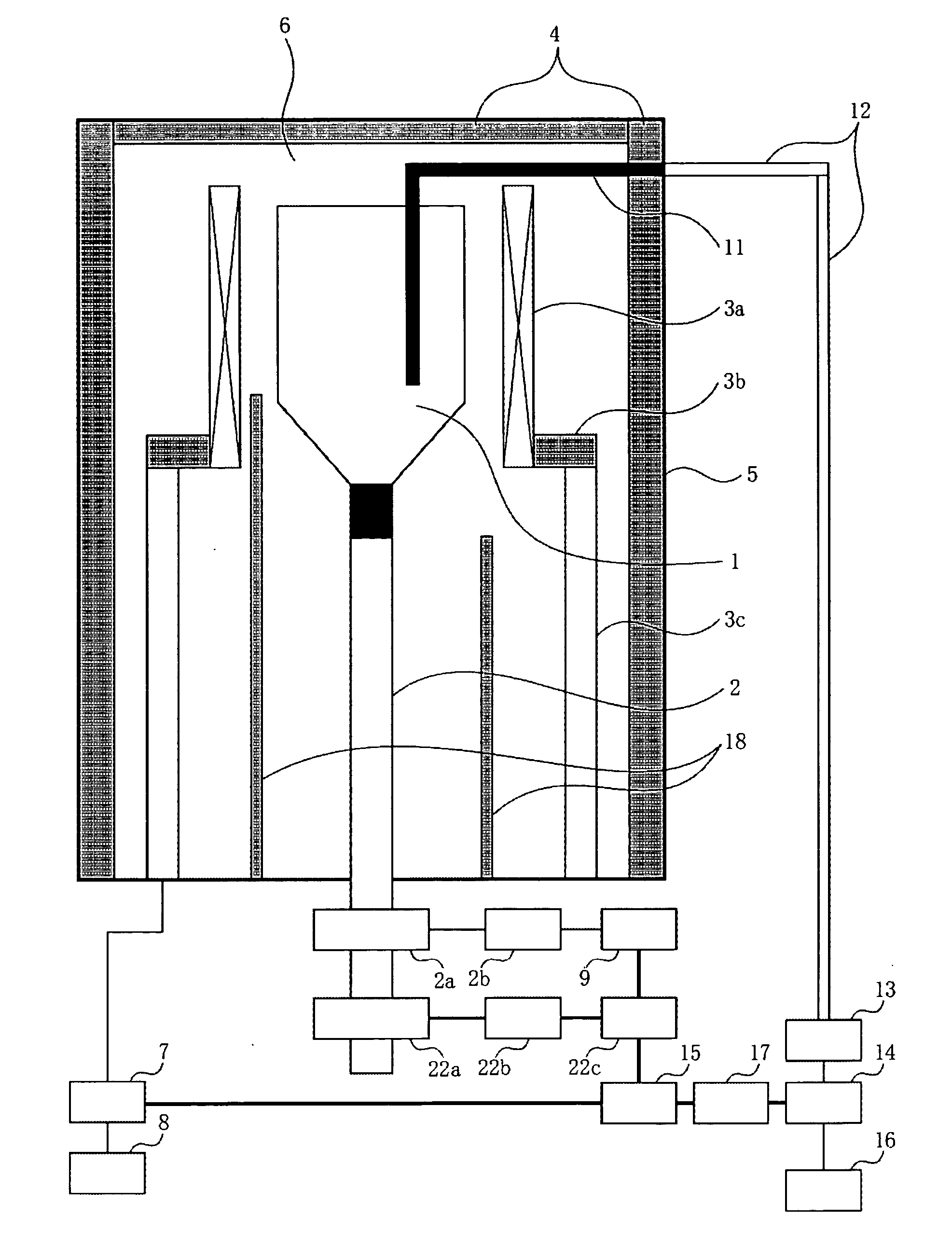

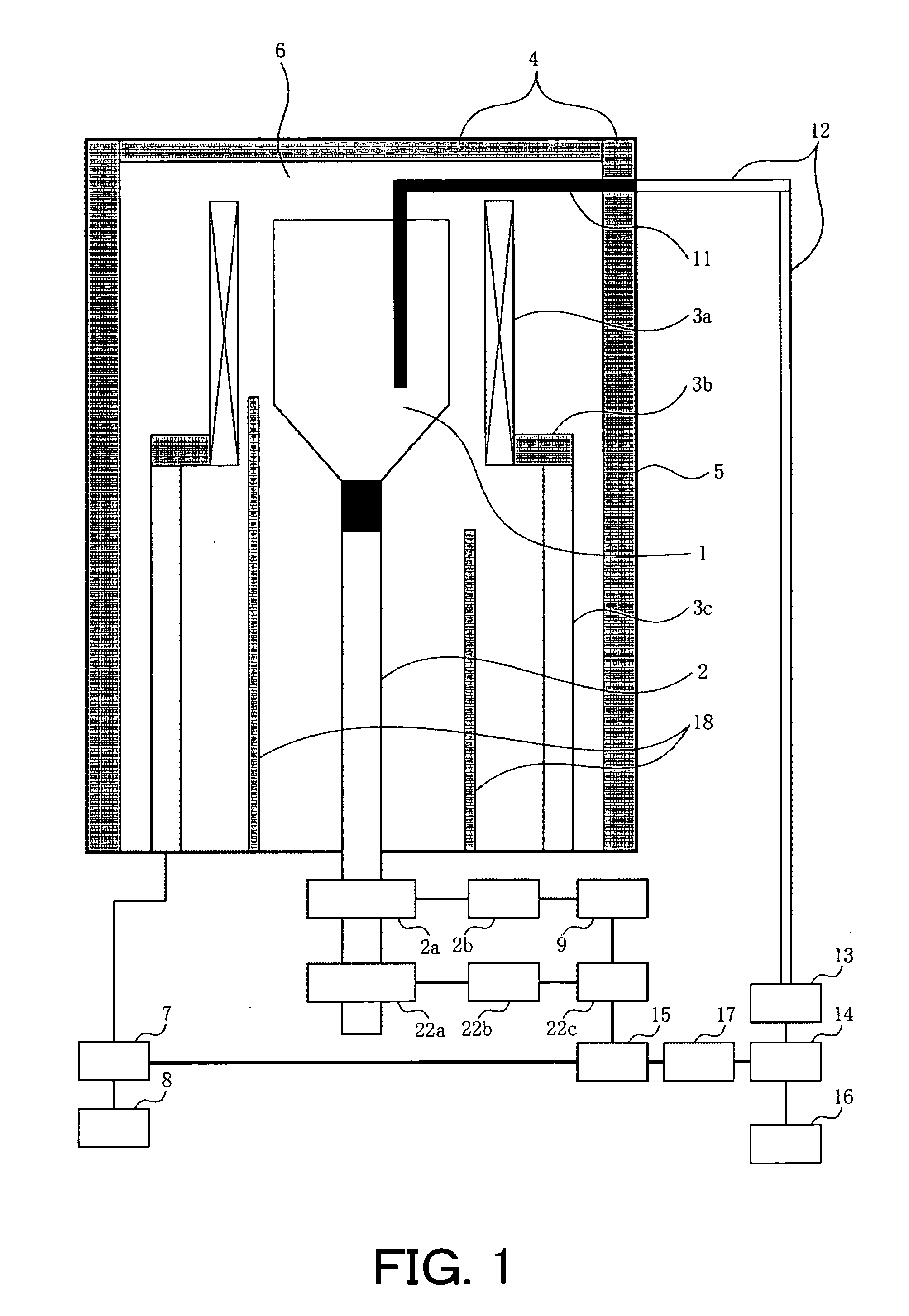

[0034] The instant embodiment explains an example of manufacturing the calcium fluoride chiefly used for an optical material by the above crystallization method.

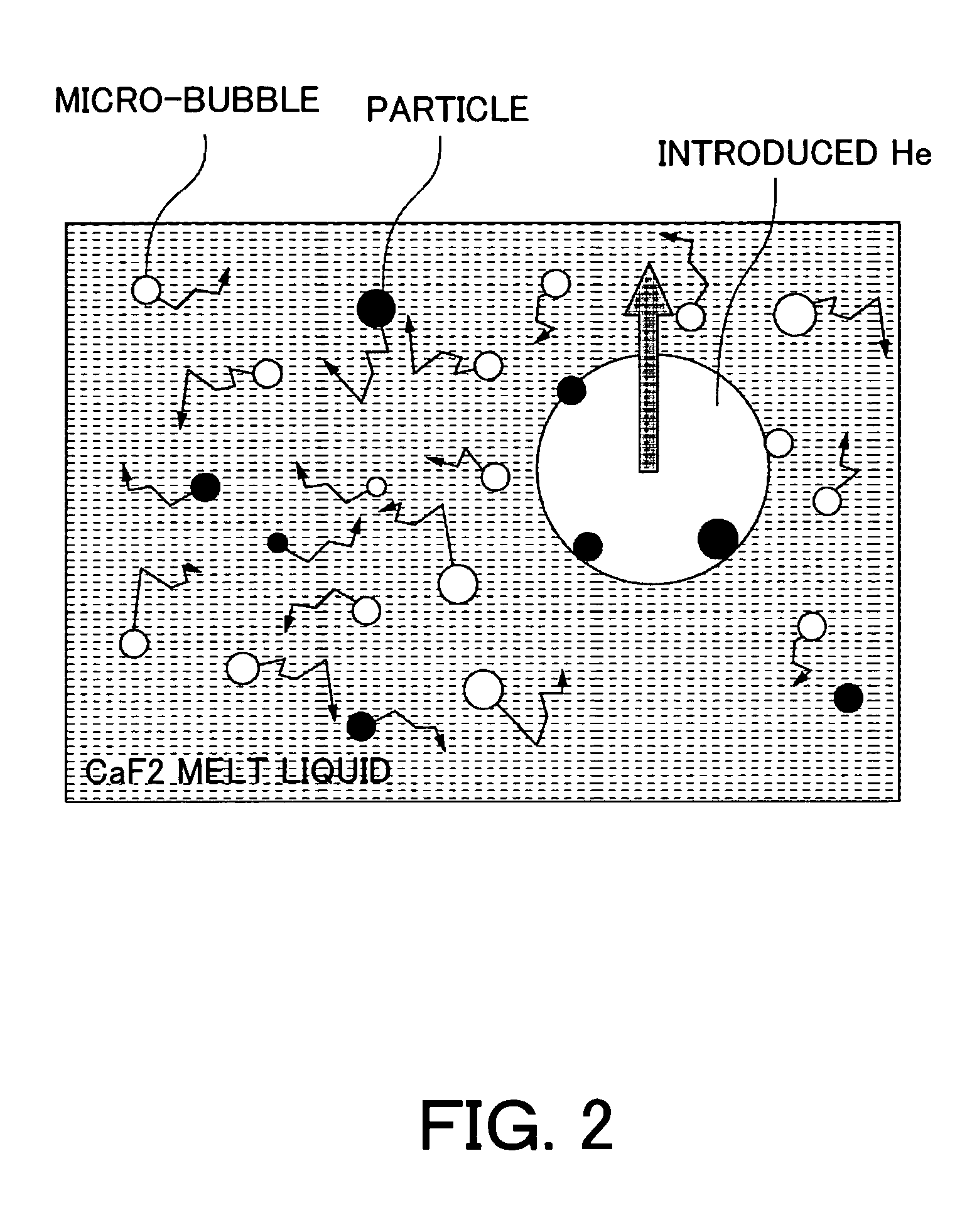

[0035] A material that adds ZnF2 of 0.1% by weight as the scavenger to high-purity calcium fluoride polycrystal which is a material of calcium fluoride single crystal is placed into the carbon crucible 1 shown in FIG. 1. After the chamber 6 is vacuum-exhausted, the side heater 3 is electrified to heat the chamber 6, the crucible 1 is adjusted to about 1360° C., and the material in the crucible 1 is melted. The melt state is maintained for about three hours for the oxygen removal reaction to occur in the melt liquid by the scavenger, and then, the gas introducing port 11 made of carbon is inserted in the crucible 1, and the state is maintained for seven hours while introducing the helium gas with 300 sccm. Meanwhile, the chamber 6 is maintained to the pressure of 1 Torr or less to easily deaerate the introduced helium gas.

[...

second embodiment

[0067]FIG. 8 is a typical sectional view of a second crystallization apparatus according to the present invention. FIG. 8 shows a structure when this invention is executed with the crystallization apparatus by Czochralski method. In the instant embodiment, a description will be given of manufacturing of lithium tantalate (LiTaO3) (hereafter, LT) crystal as one example of the grown crystal.

[0068] In FIG. 8, a crucible 1a that houses a melting material as a crystalloid is installed in the housing 5 that form the chamber 6. An insulator 4 is installed inside the housing 5, and protects the housing 5 from the high-temperature. The chamber 6 is vacuum exhausted to the pressure of 1E-4 or less (Torr) by the exhaust apparatus (not shown).

[0069] A RF (radiofrequency generation) coil 21 that heats the material in the crucible 1a is arranged outside of the chamber 6. The RF coil 21 is supplied an electric power from a radiofrequency generation power source 20 that is controlled by a power s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com