Filtering device for vacuum cleaner

a filtering device and vacuum cleaner technology, applied in the field of vacuum cleaners, can solve the problems of deteriorating suction force, difficult discharge, and filter cleaning or replacement periodicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

[0034] There may exist a plurality of embodiments of a filtering device for a vacuum cleaner in accordance with the present invention, and hereinafter, the most preferred embodiment will be described.

[0035] In addition, the same reference numerals will be given to the same components as the conventional art.

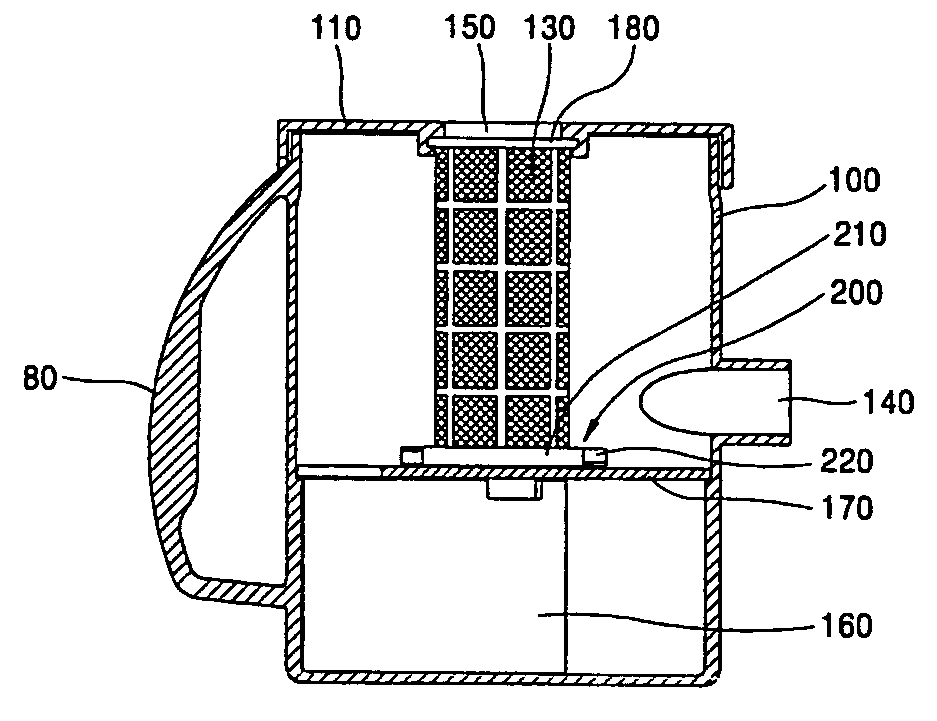

[0036]FIG. 5 is a disassembled perspective view of a filtering device for a vacuum cleaner in accordance with the present invention, FIG. 6 is a longitudinal sectional view taken along line VI-VI of FIG. 5 and showing an assembled filtering device in accordance with the present invention, and FIG. 7 is a perspective view of a filter cleaning unit in accordance with the present invention.

[0037] As shown therein, a filtering device of a vacuum cleaner in accordance with the present invention is provided with a knob 80 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com