Component specific tube banks for hydroforming body structure components

a technology for hydroforming body structure components and components, applied in the field of hydroforming component specific blanks, can solve the problems of increasing reducing the number of parts, and increasing the cost of manufacturing, so as to facilitate the efficient and versatile shaping of automotive body components and reduce the amount of packaging space required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is illustrated with respect to a method for molding a component, particularly suited to the automotive field. The present invention is, however, applicable to various other uses that may require hydroformed components, as will be understood by one skilled in the art.

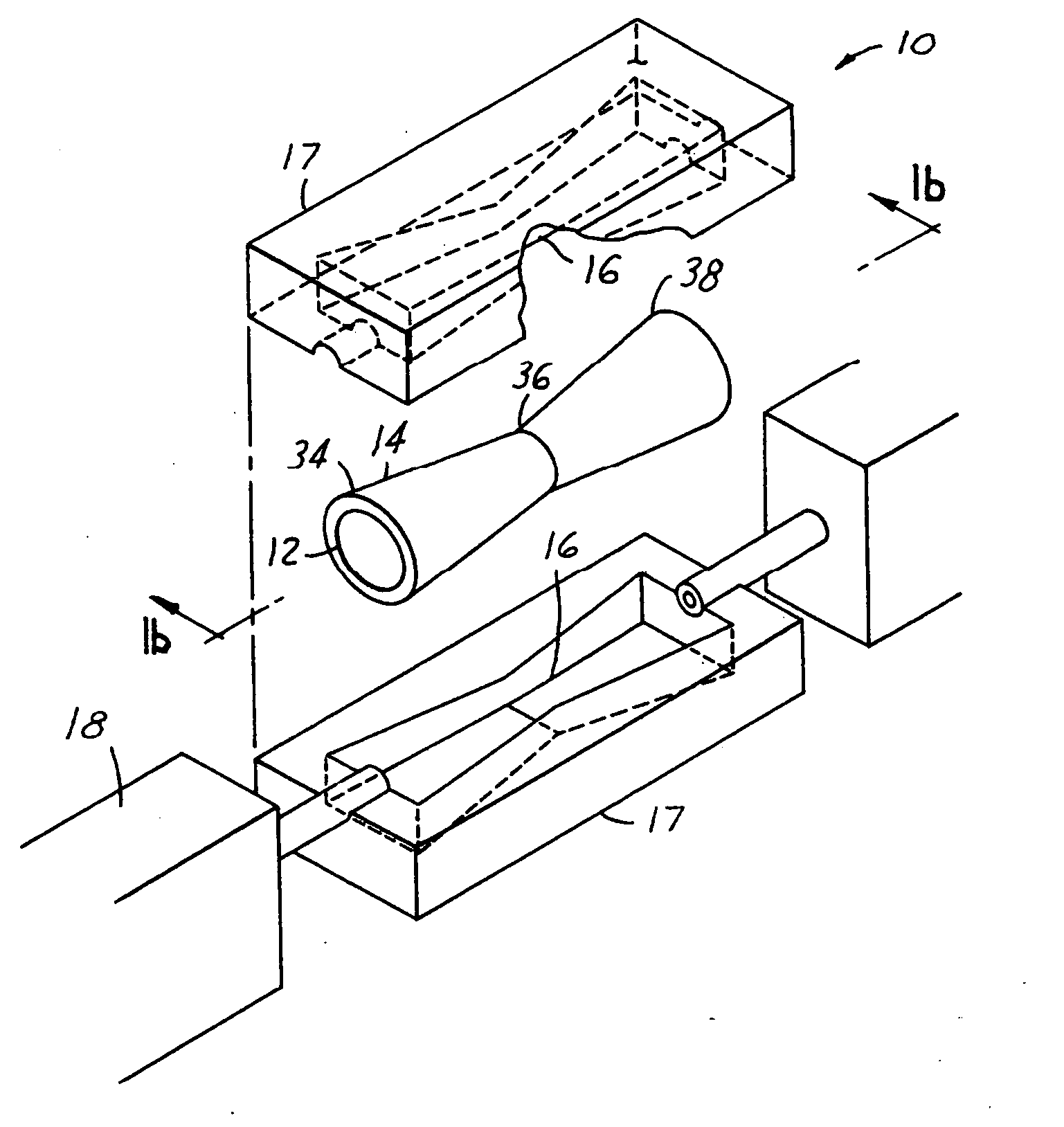

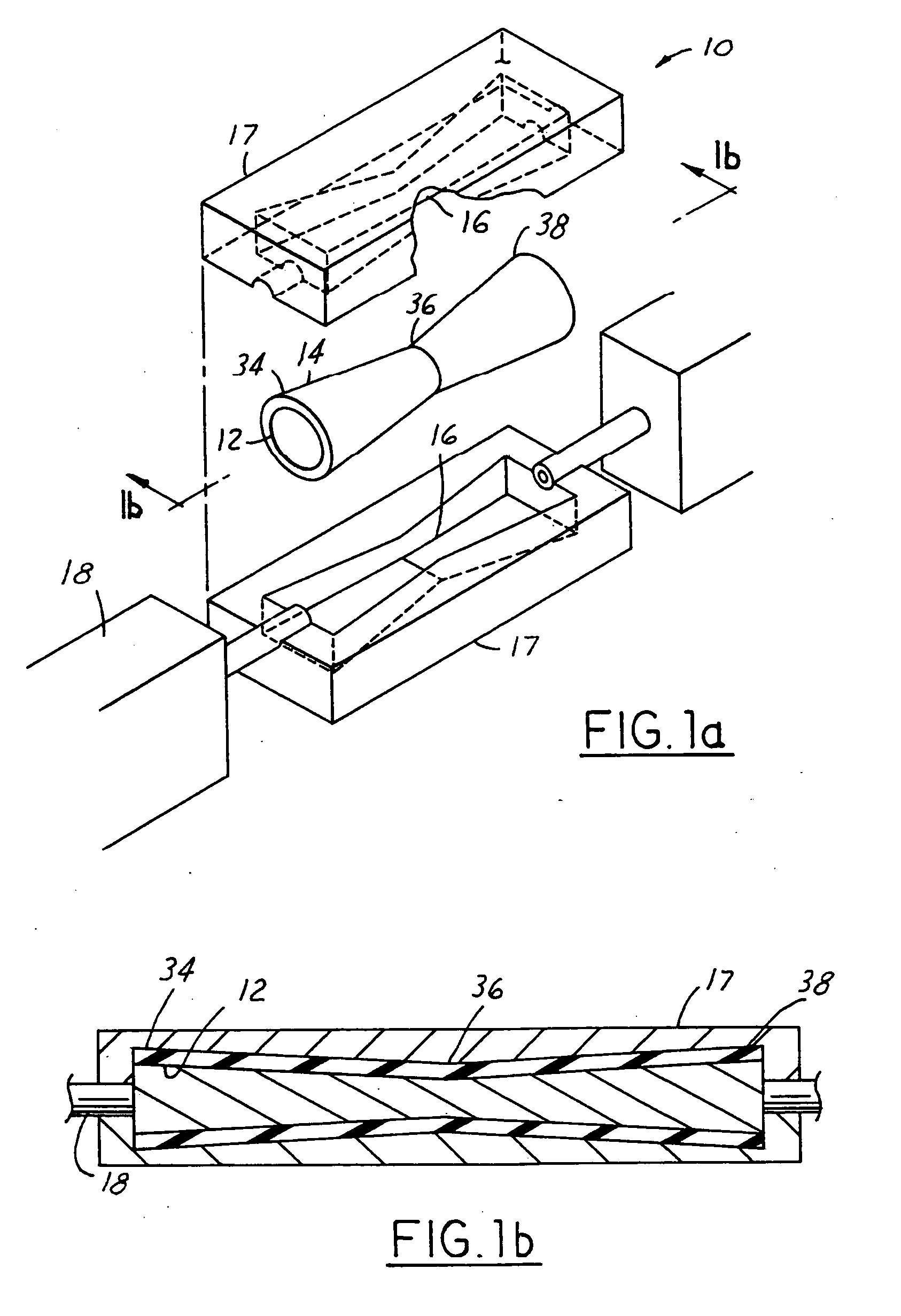

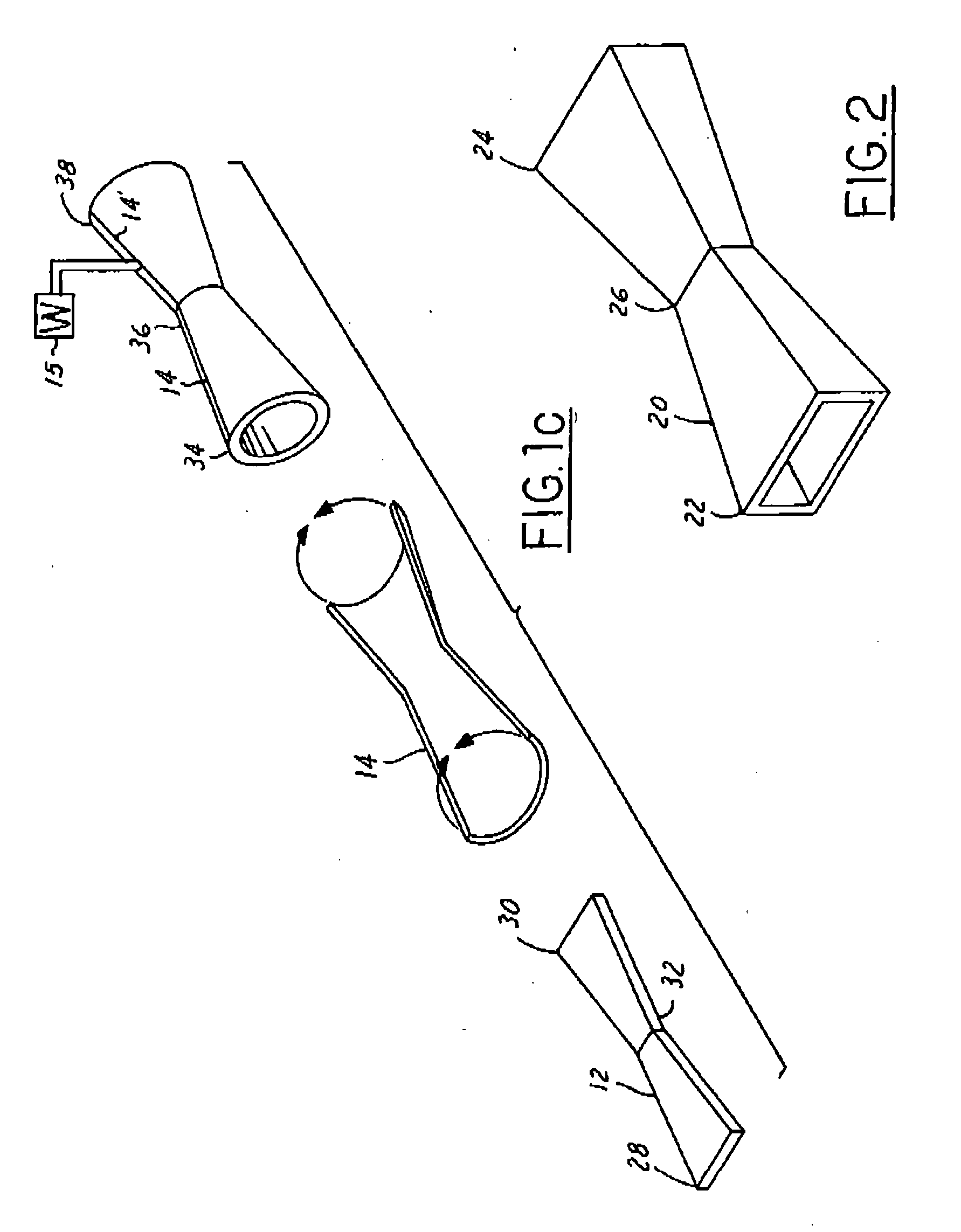

[0022] Referring to FIGS. 1a, 1b, and FIG. 2, a dual conical tube 14 for use in a hydroforming method 10, including a substantially bow tie shaped blank 12, is disclosed. The blank 12 is adapted to be rolled to form the dual conical tube 14. The blank 12 is here illustrated as a substantially bow tie shaped blank 12, however, it is to be understood that numerous alternate blank shapes may be used depending on specific part parameters, as one skilled in the art would realize.

[0023] The substantially bow tie shaped blank 12 is reinforced, depending on material and tensile requirements for the blank 12 prior to the rolling and forming processes, as will be discussed later. Alternate embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cross sectional area | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| molding | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com