Ball for use in a tire assembly

a tire assembly and ball technology, applied in the field of balls for use in tire assemblies, can solve the problems of increasing the internal pressure of a particular ball, and achieve the effects of improving traction, reducing the probability of a flat tire, and reducing the risk of damage to the tir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

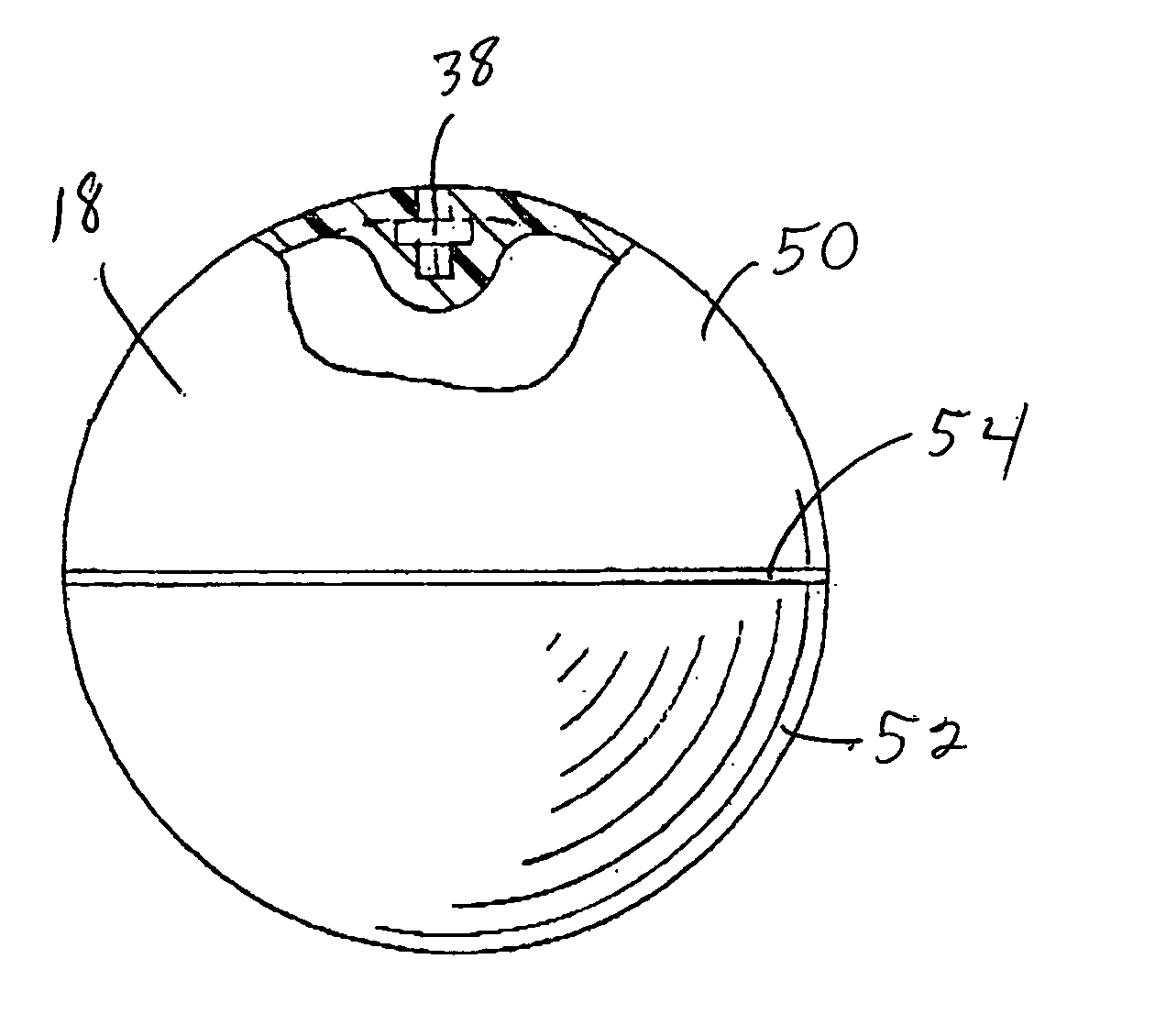

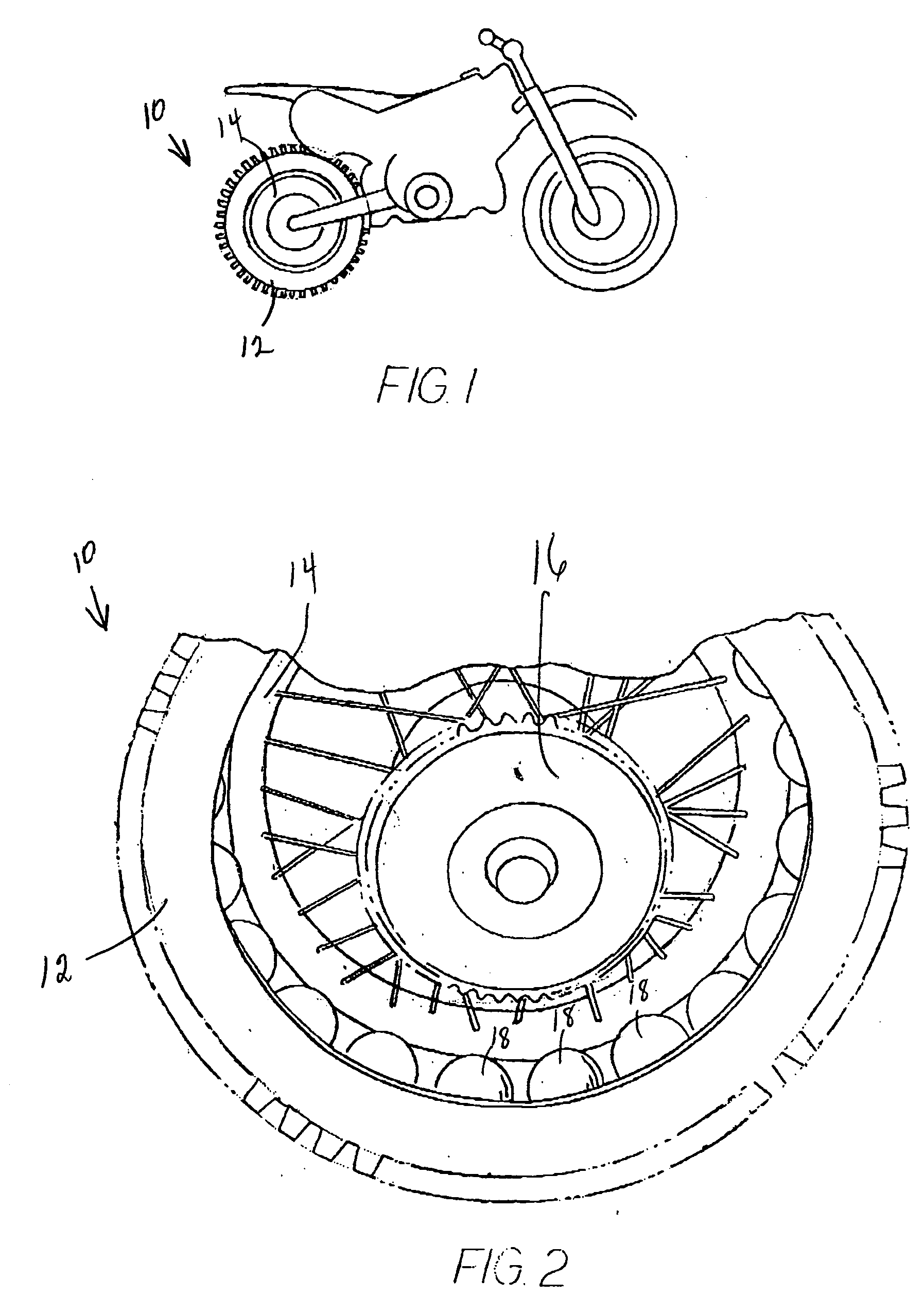

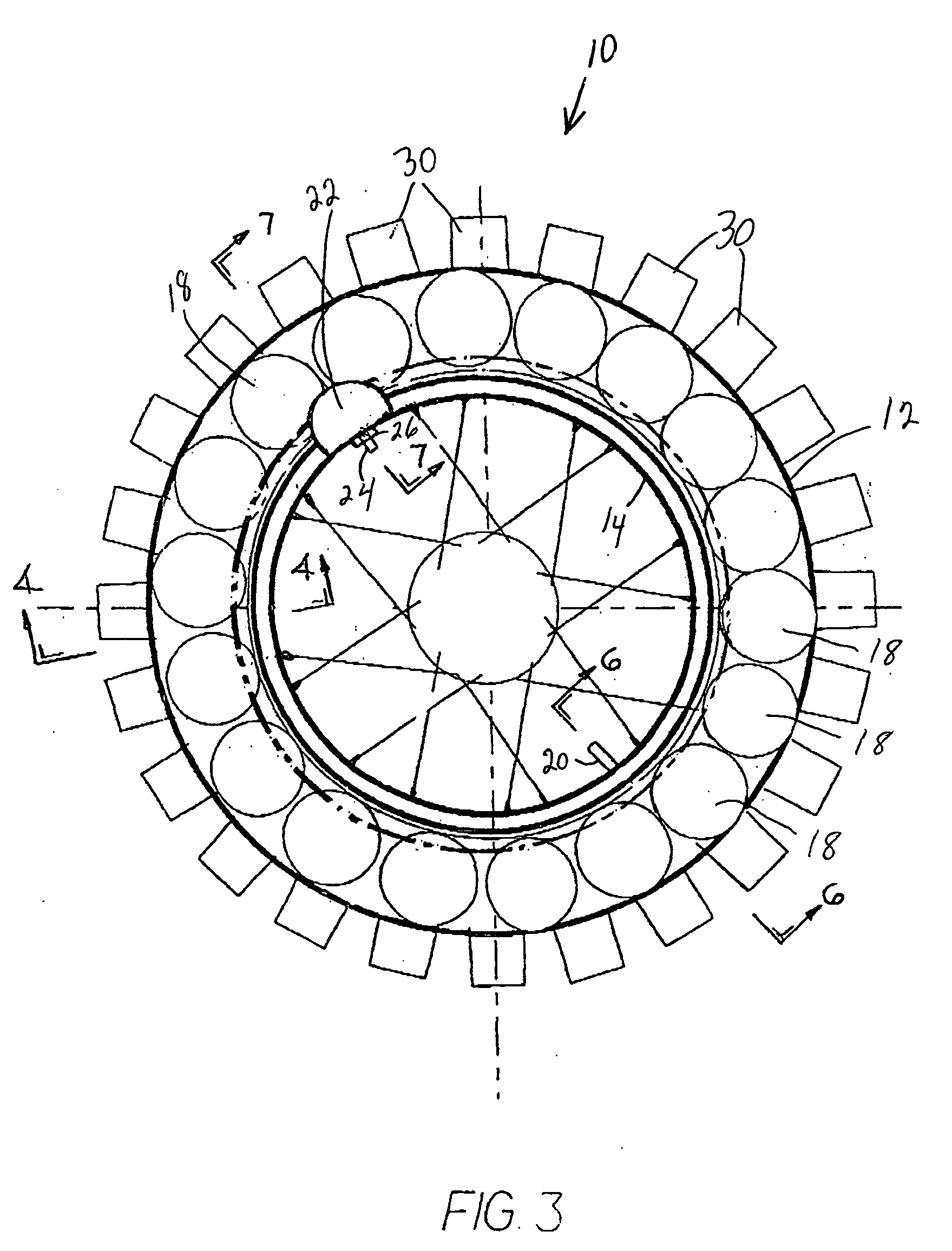

[0026]FIGS. 1-4 and 6-15 show a first tire assembly 10, made in accordance with the present invention. The tire assembly 10 includes a tire 12, which is mounted on a rim 14, which, in turn, is mounted on a hub 16. In this preferred embodiment, the tire 12 is a standard tire, and the rim 14 is a standard safety rim.

[0027] Between the rim 14 and the tire 12 are individual balls 18. The balls substantially fill the empty space between the rim 14 and the tire 12. The number, size, and shape of the balls 18 are selected depending upon the dimensions of the tire 12 and rim 14. While this view shows the ball 18 as having a substantially spherical shape, that is due to the fact that this particular tire casing 12 and rim 14 together form a void space with a substantially circular cross-section. If the rim 14 were substantially wider than the height of the tire casing, or if the height of the tire casing were substantially taller than the width of the rim, then the balls 18 preferably would...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com