Crown closure

a technology of crown closure and crowbar, which is applied in the field of improved container closure, can solve the problems of unsatisfactory crown closure, 21 rounded grooves of crown closure and 29 grooves, and neither development solves the present problem, and achieves the effect of less force or torque and convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

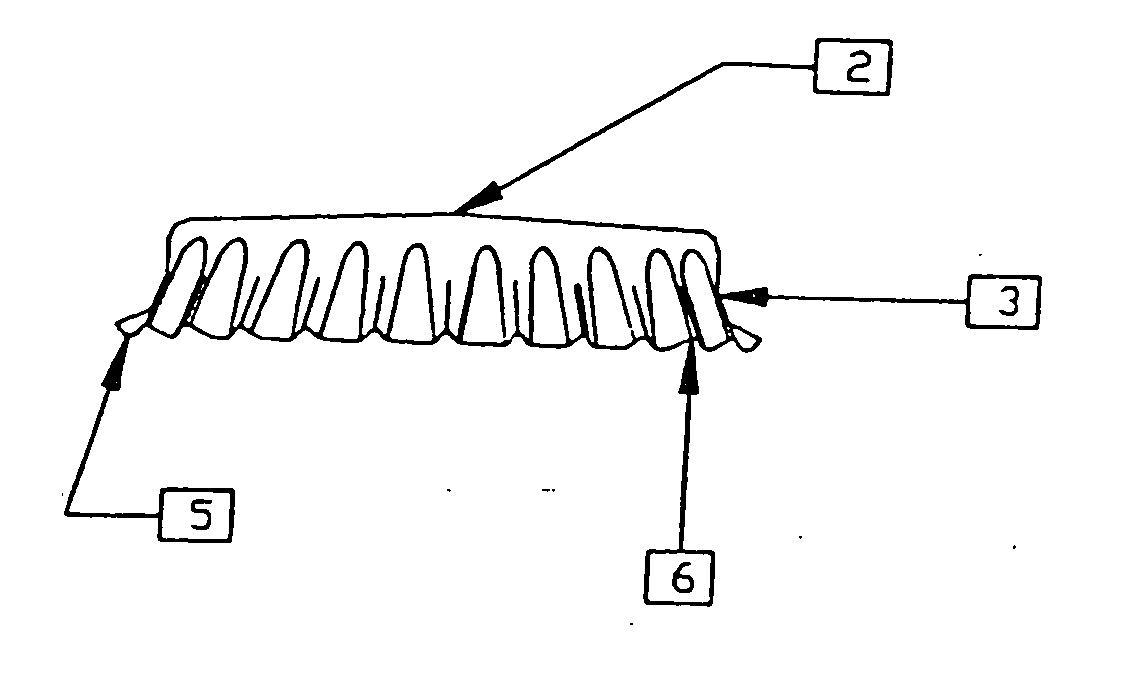

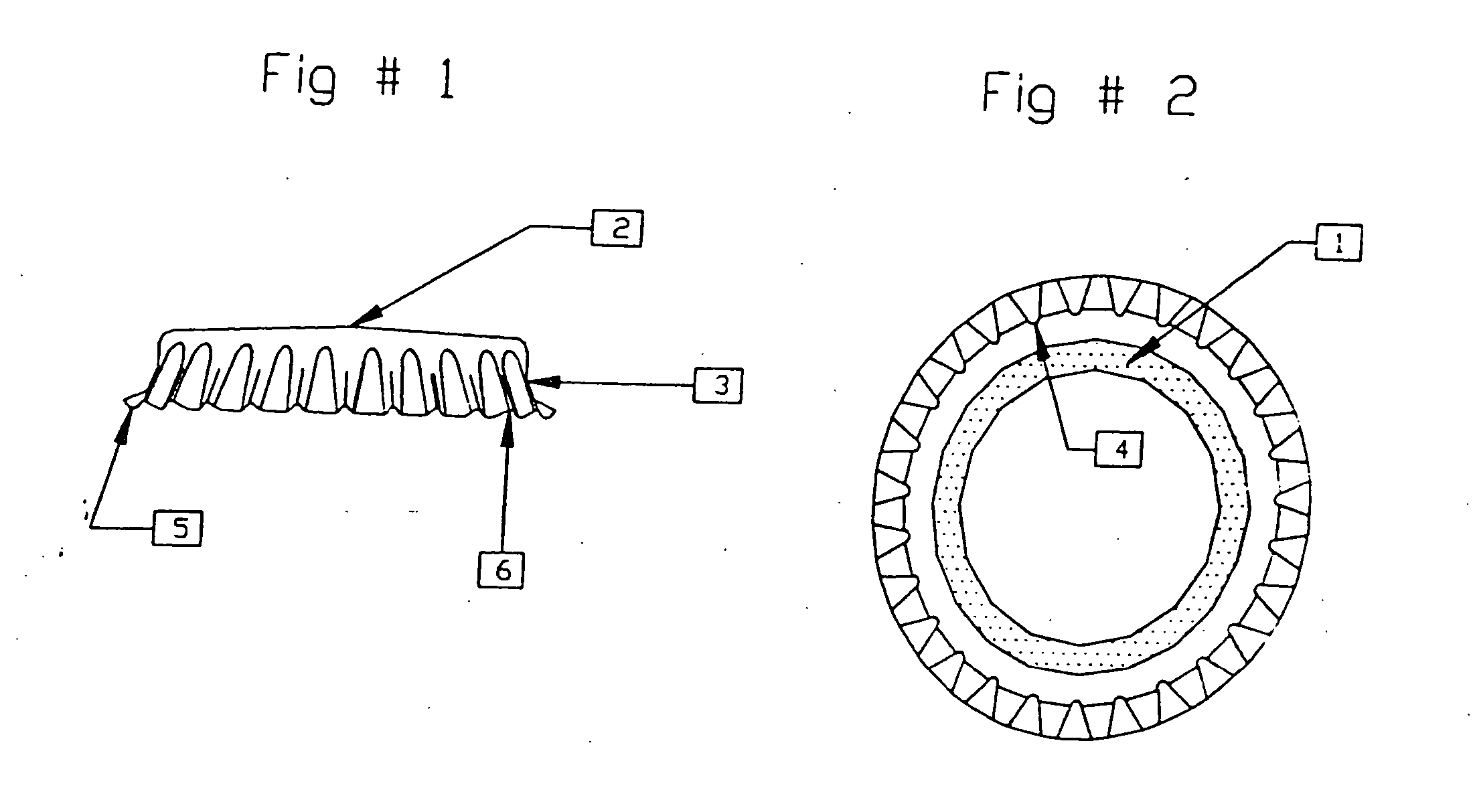

[0023] According to a preferred embodiment, the torque required to remove the crown closure with 27 grooves of the present invention is lower than that required to remove standard crown closures with 21 grooves. More specifically, the torque required to remove the crown closure of the present invention is from about 2 in lb to about 9 in lb, preferably from about less than 2 in lb to about 4 in lb. As discussed above, the torque required to remove a standard crown closure with 21 grooves is from about 8 in lb to about 13 in lb, and in some cases as high as 15 in lb.

[0024] As less torque is needed to remove the crown closure of the present invention, the result is a softer feel upon removal of the closure that benefits consumers and helps reduce the number of unsatisfied consumers.

[0025] The crown cap of the present invention is preferably provided with a plastic packing in the interior 1 that may, optionally, be PVC (polyvinyl chloride), PVC-free or another thermoformed material t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com