Device for opening a tubular bag and its application

a tubular bag and opening device technology, applied in the direction of tubular containers, pliable tubular containers, containers, etc., can solve the problems of inability to flow freely, known mechanisms have certain disadvantages, paste can be held back temporarily, etc., to prevent the tube from twisting and the resistance of viscous paste to be kept low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

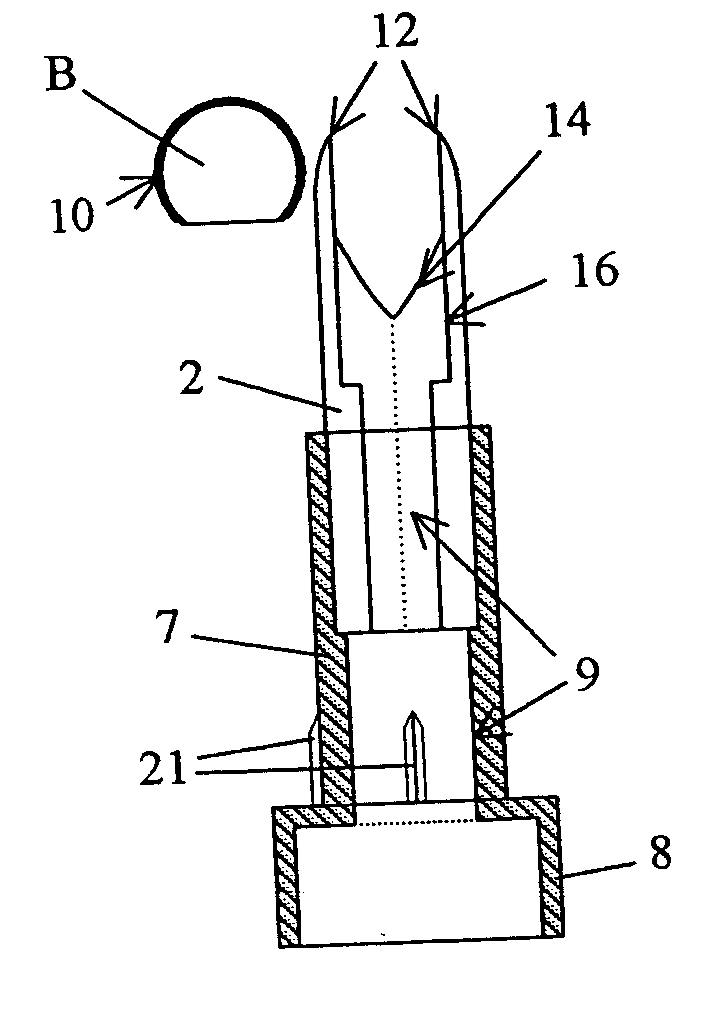

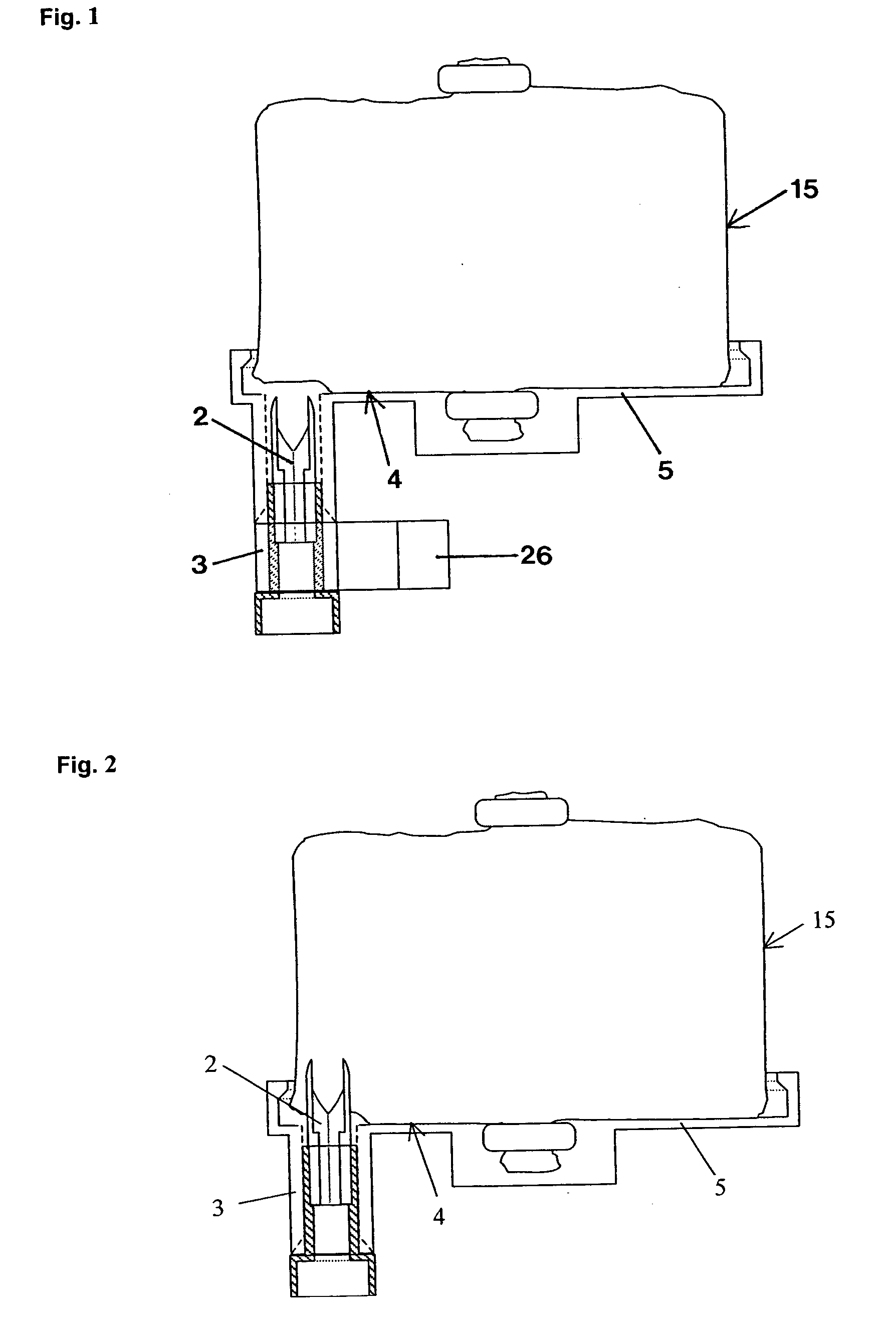

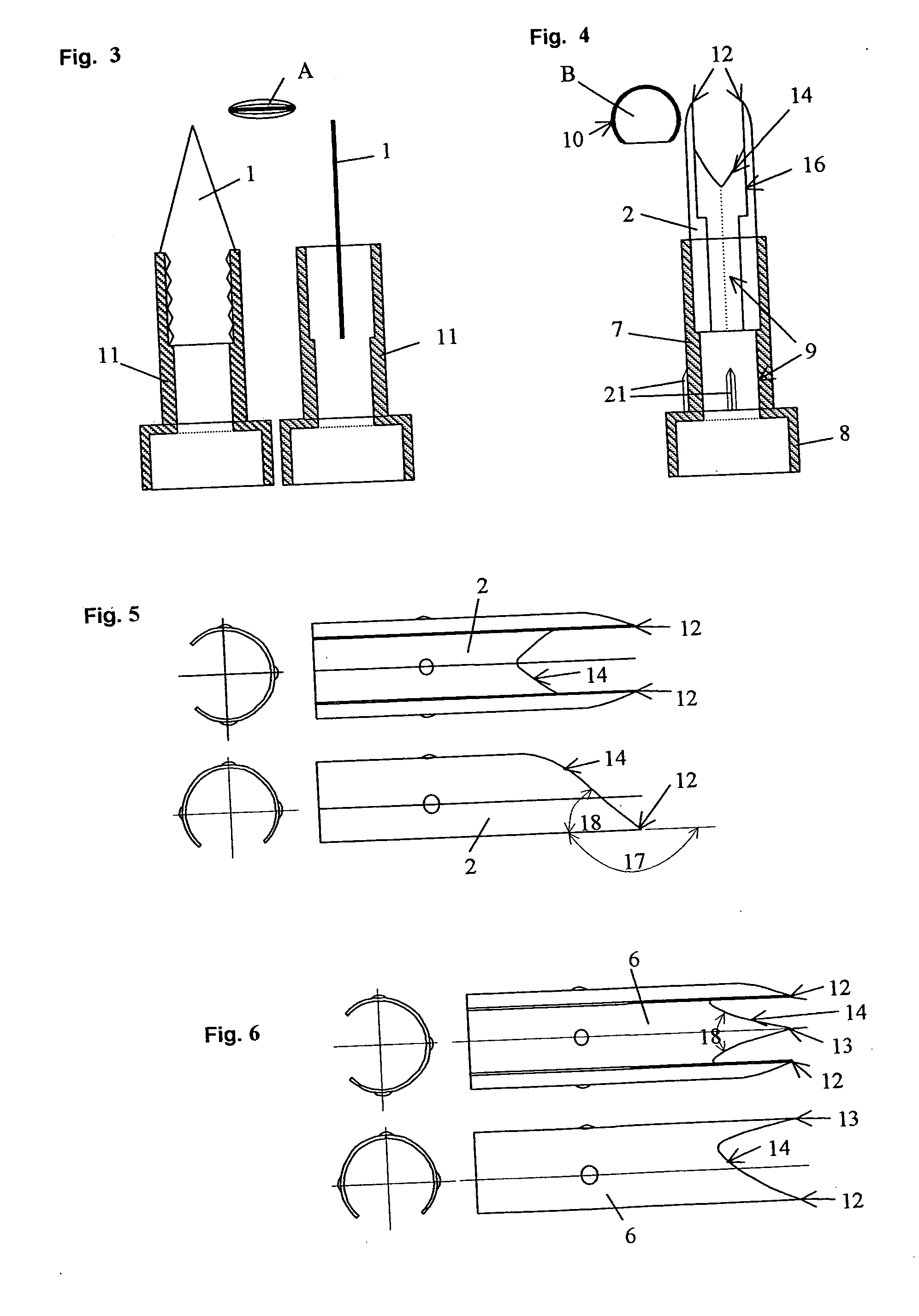

[0014] It proves to be advantageous that the inserting tube and the blade are made of different materials, namely, the tube is made of a sealing material and the blade is made of a sturdy material. Furthermore, it is advantageous if the blade has at least two pointed tips that are connected by a slanting or bent cutting edge. The blade preferentially creates a non-linear opening in the foil of the tubular bag by which the resistance for viscous pastes can be kept low.

[0015] The blade preferentially has at least two pointed tips that are connected by a cutting edge. In order to guarantee the optimal functioning of the blade, it is necessary to design the blade such that it is very pointed, sharp-edged and stiff, as would be possible using steel or ceramics for instance.

[0016] It is possible to design the blade and opening tube out of one unit (combination component). Since the side of the opening tube facing away from the blade must be essentially more flexible and softer in order ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com