Inspection device of winding appearance of tape and improvement processing method for the same

a technology of inspection device and winding appearance, which is applied in the direction of speed-changing/reversing arrangement, applications, instruments, etc., can solve the problems of inability to inspect the damage to the projecting part of the tape from the winding surface formed by the tape edges, and inability to obtain good winding appearance of magnetic tape. , to achieve the effect of good winding appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

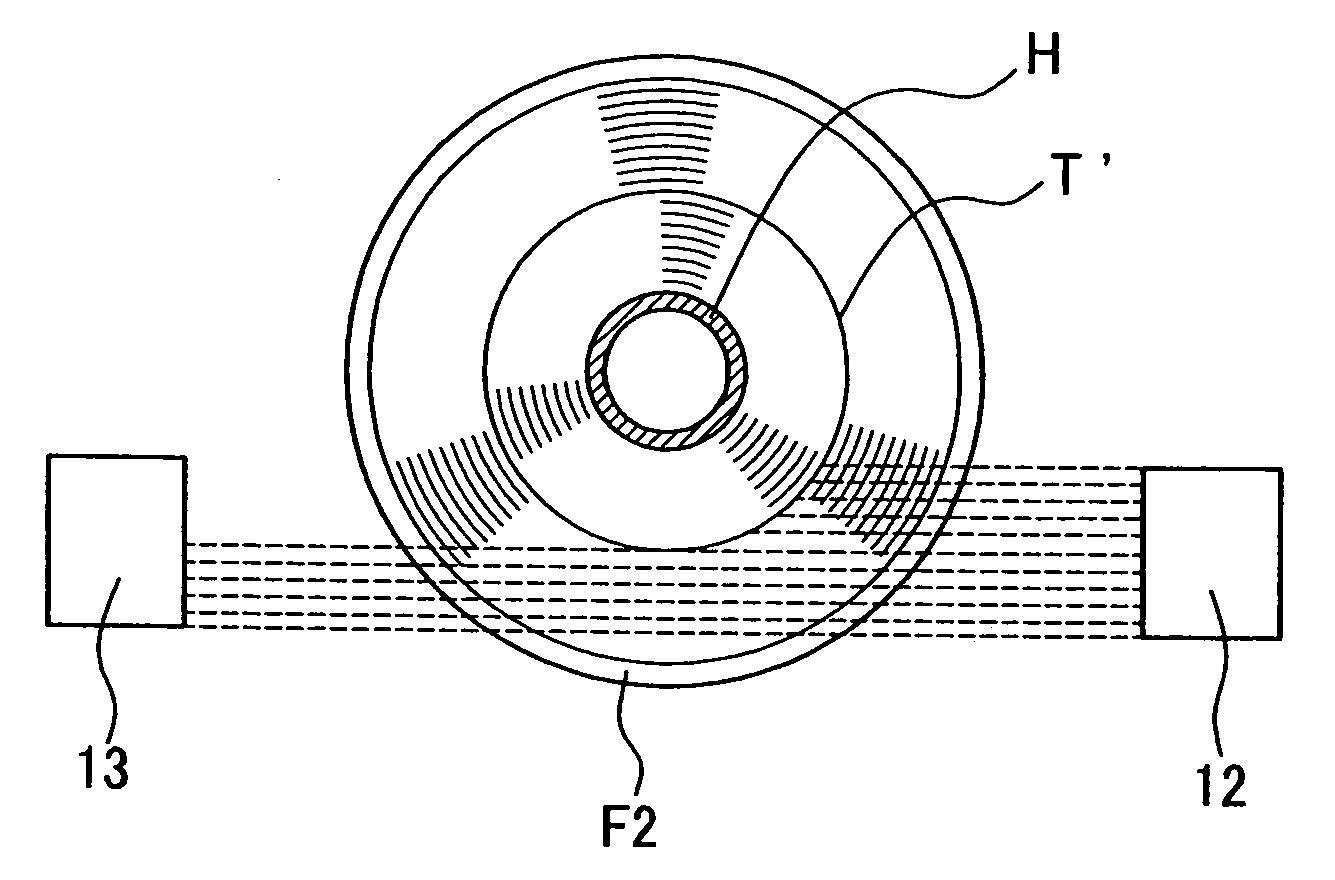

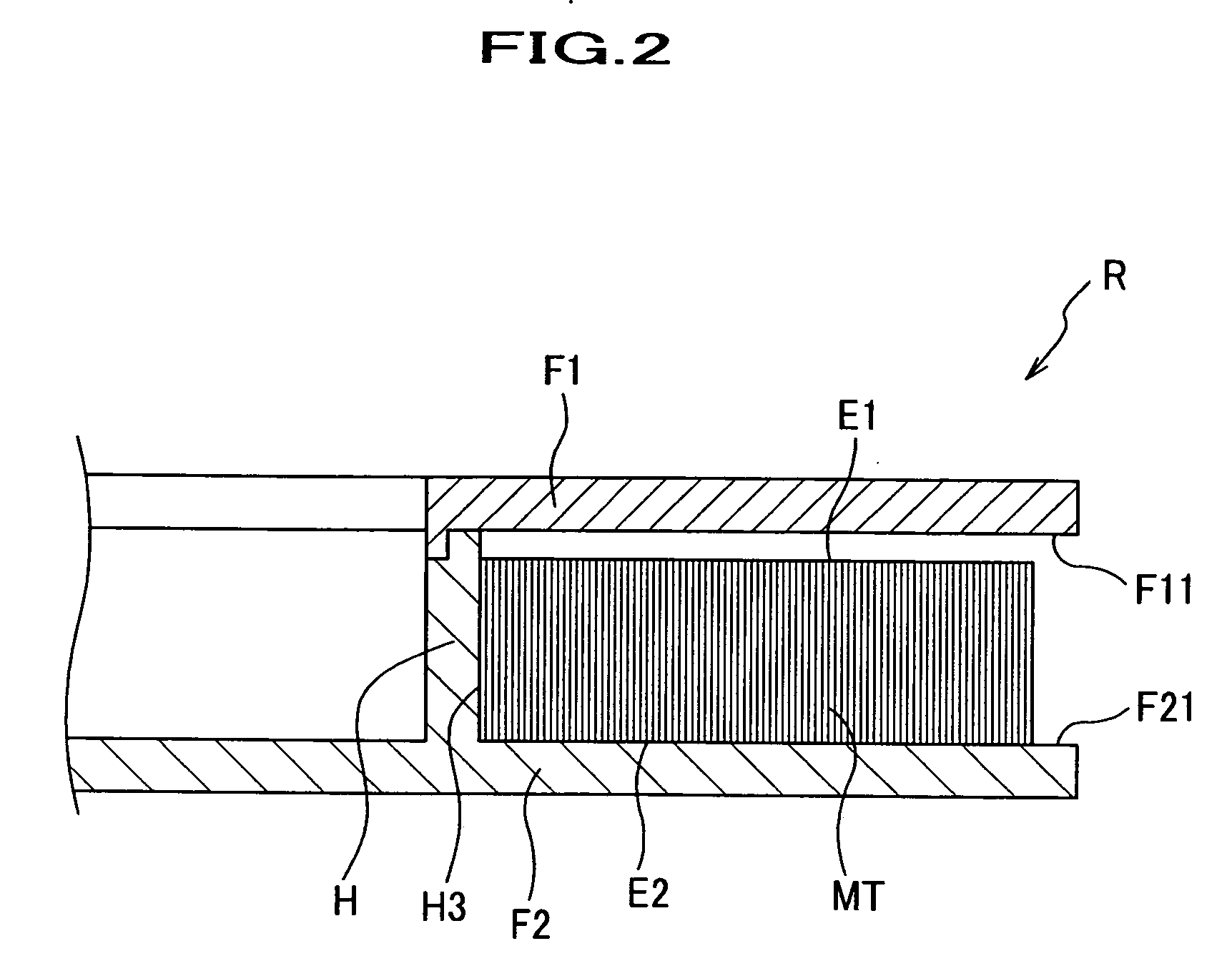

[0047] By applying the present invention, this embodiment shows a winding appearance inspection device of film T (tape) wound on roll body core H (roll body core) of tape reel R. Wherein upper flange F1 and lower flange F2 are formed on both ends of the roll body core (roll body core) H.

[0048] As shown in FIG. 4, winding appearance inspection device 10 of this invention mainly includes a main body 11, a light transmissive device 12, and a receiver 13. The main body 11 mainly includes a base part 11a formed in a nearly rectangular form in plan view, a reel installation part 11b for installing the tape reel R, a light transmissive device installation part 11c for installing the light transmissive device 12, and a light receiver installation part 11d for installing the light receiver 13.

[0049] The reel installation part 11b is formed so that it may project from nearly the center of the base part 11a. The face gear, which is not shown, for receiving rotation driving force is formed on...

second embodiment

[0058] This embodiment presents an inspection device that inspects a winding appearance of magnetic tape cartridge C having two tape reels R of the first embodiment. The components and portions of the same designation as those in the drawings used for the explanation for the first embodiment are designated the same numerals and signs, omitting and simplifying the overlapping explanation.

[0059] As shown in FIG. 7, a winding appearance inspection device 20 mainly includes a light projector 21 that irradiates light along the winding surface S of the magnetic tape (tape) toward roll body core H, and a receiver 22 that receives the light from the light projector 21 which is reflected by projecting magnetic tape MT′. The light projector 21 is installed so that the light may be irradiated from the exterior of magnetic tape cartridge C to roll body core H of inside. Therefore, the light projector 21 is installed in the position where the roll body core H of inside can be examined with open...

third embodiment

[0067] This embodiment, as shown in FIG. 10, presents an inspection device of the winding appearance of the magnetic tape cartridge C of the second embodiment. Therefore, the components and portions of the same designation as those in the drawings used for the explanation for the second embodiment are designated the same numerals and signs, omitting and simplifying the overlapping explanation.

[0068] As shown in FIG. 10, an winding appearance inspection device 30 mainly includes a lighting device 31 (light projector) that irradiates the light heading for the roll body core H along the winding surface S of the magnetic tape MT, and a CCD camera (imaging device) 32 that images the light from the lighting device 31 reflected by the magnetic tape MT′ that projects from the roll body core H and the winding surface S. Lighting device 31 is a small device using an optical fiber. Therefore, if only a luminescence portion is pulled out by a suitable method and fixed, the installation to a na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com