Longitudinally expandable plastic bottle, and method and apparatus for manufacturing the same

a plastic bottle and longitudinal expansion technology, applied in the field of longitudinal expansion plastic bottles and method and apparatus for manufacturing the same, can solve the problems of affecting the living environment, affecting the efficiency of public utilities, and putting a heavy burden on the labor costs of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

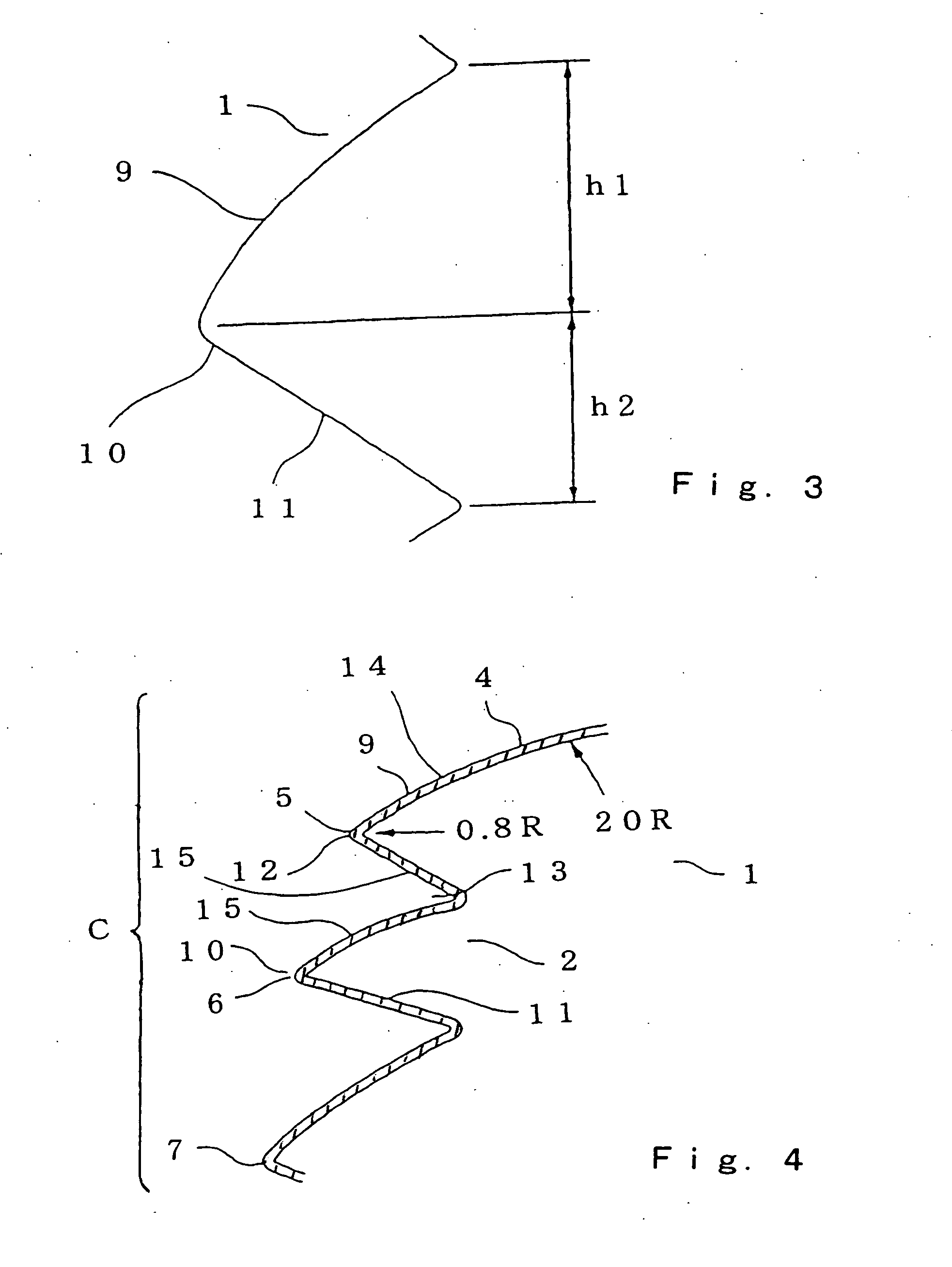

[0125] The following is a description of an example of a mold suitable for mass production of the bottle 1 in accordance with the present invention.

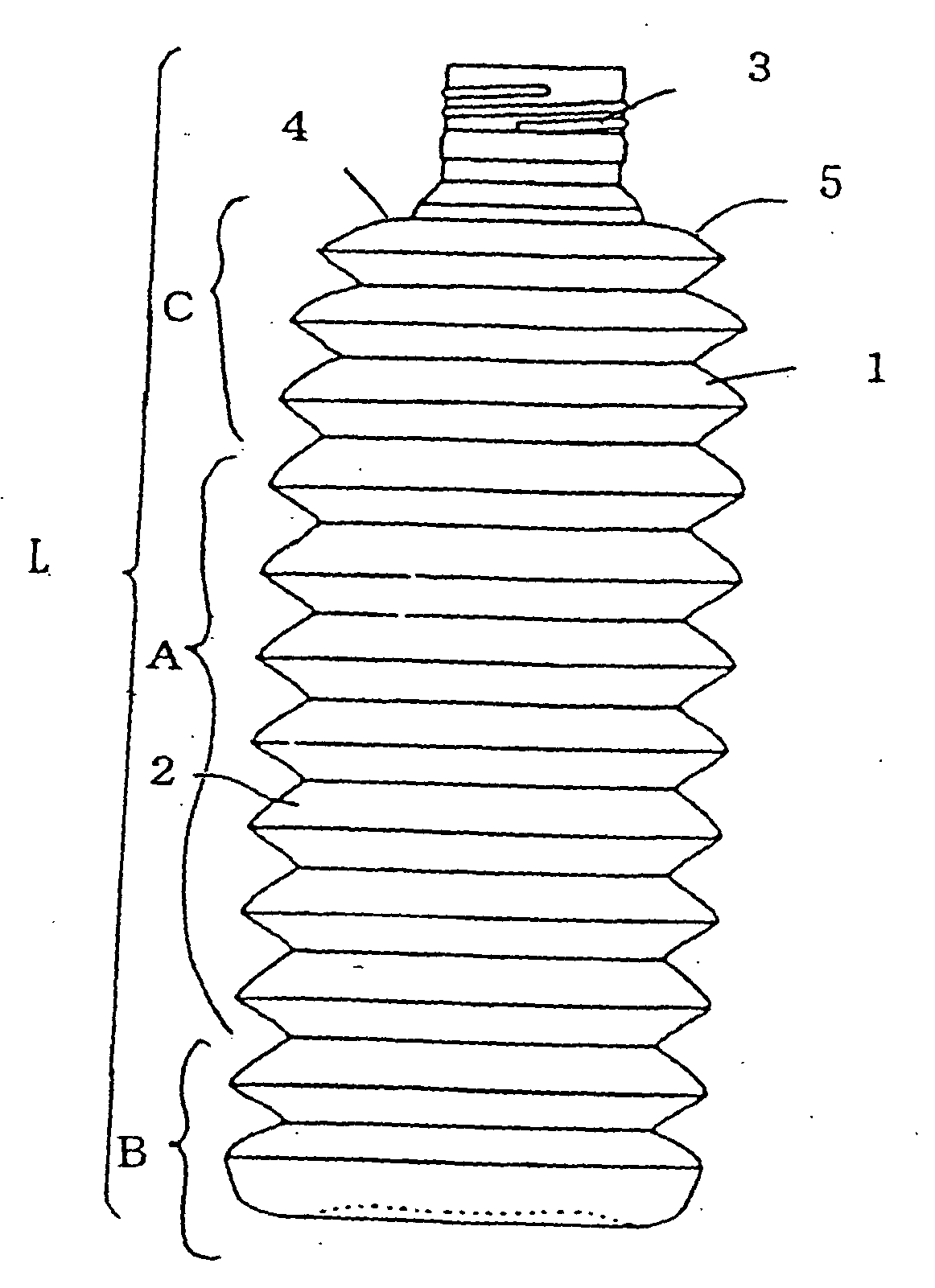

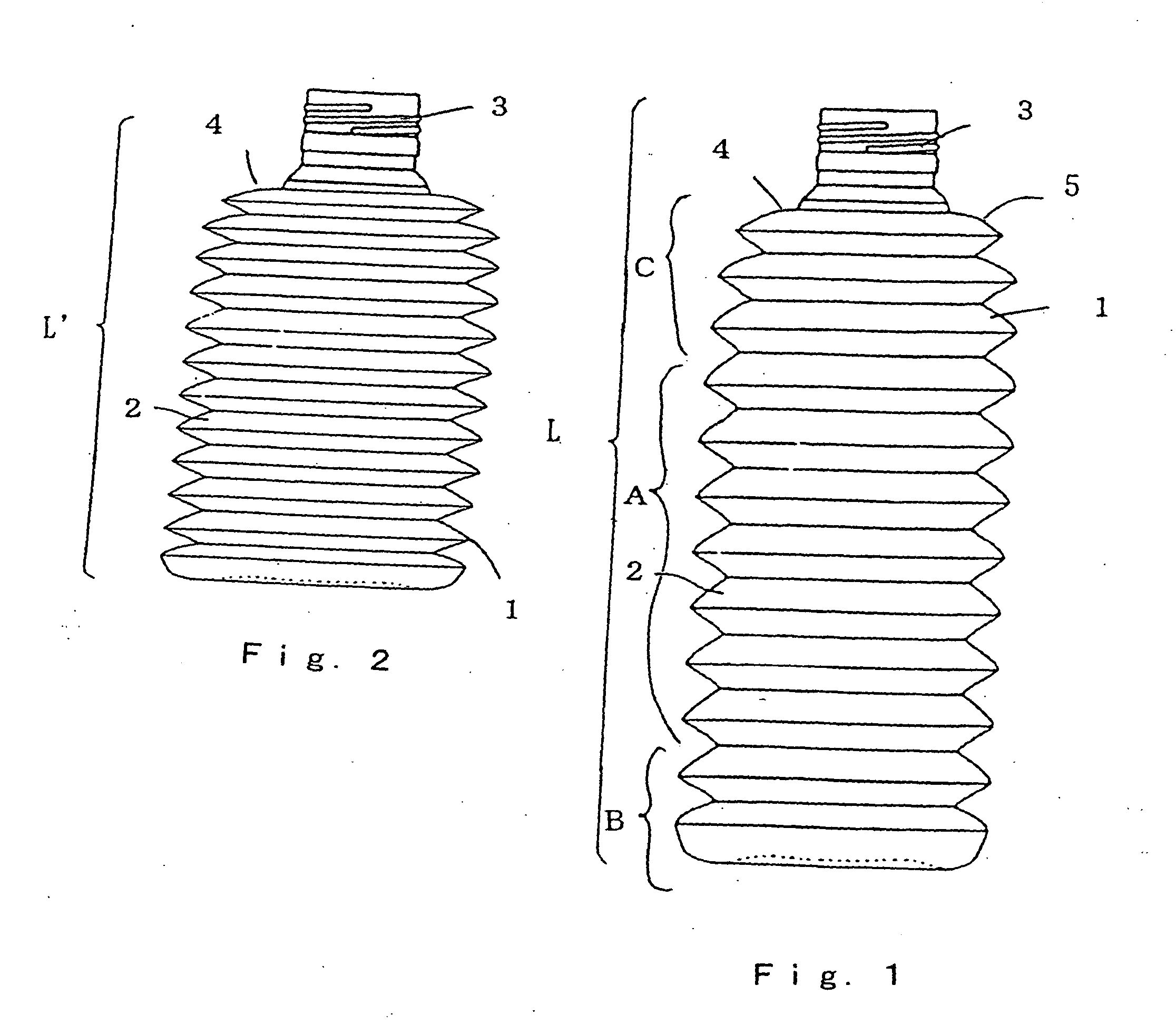

[0126] In FIG. 5, reference numeral 16 denotes a two-piece mold for manufacturing the cylindrical bottle 1 shown in FIG. 1. A preform 17 can be inserted through the bottom surface of the mold 16.

[0127] Explanation is given of a process for manufacturing the bottle 1 using the mold 16 in this example. First, the mold 16 is in an opened state.

[0128] In this state, the preform 17 is automatically inserted into the mold 16 from the downside. Then, after the preform 17 has been heated uniformly, high-pressure air of about 40 kilograms is sent into the preform 17 to expand the preform 17, by which the bottle 1 is formed.

[0129] The bottle 1 thus obtained has a height approximately equal to that at the time when the bottle 1 is filled with contents such as juice.

[0130] In FIG. 6, reference numeral 18 denotes a mechanism for compression mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com