Dough storage container system

a storage container and container technology, applied in the field of dough storage container systems, can solve the problems of inconvenient use, inability to reliably stack, and inability to firmly lock together, and achieve the effect of less space and resistance to toppling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

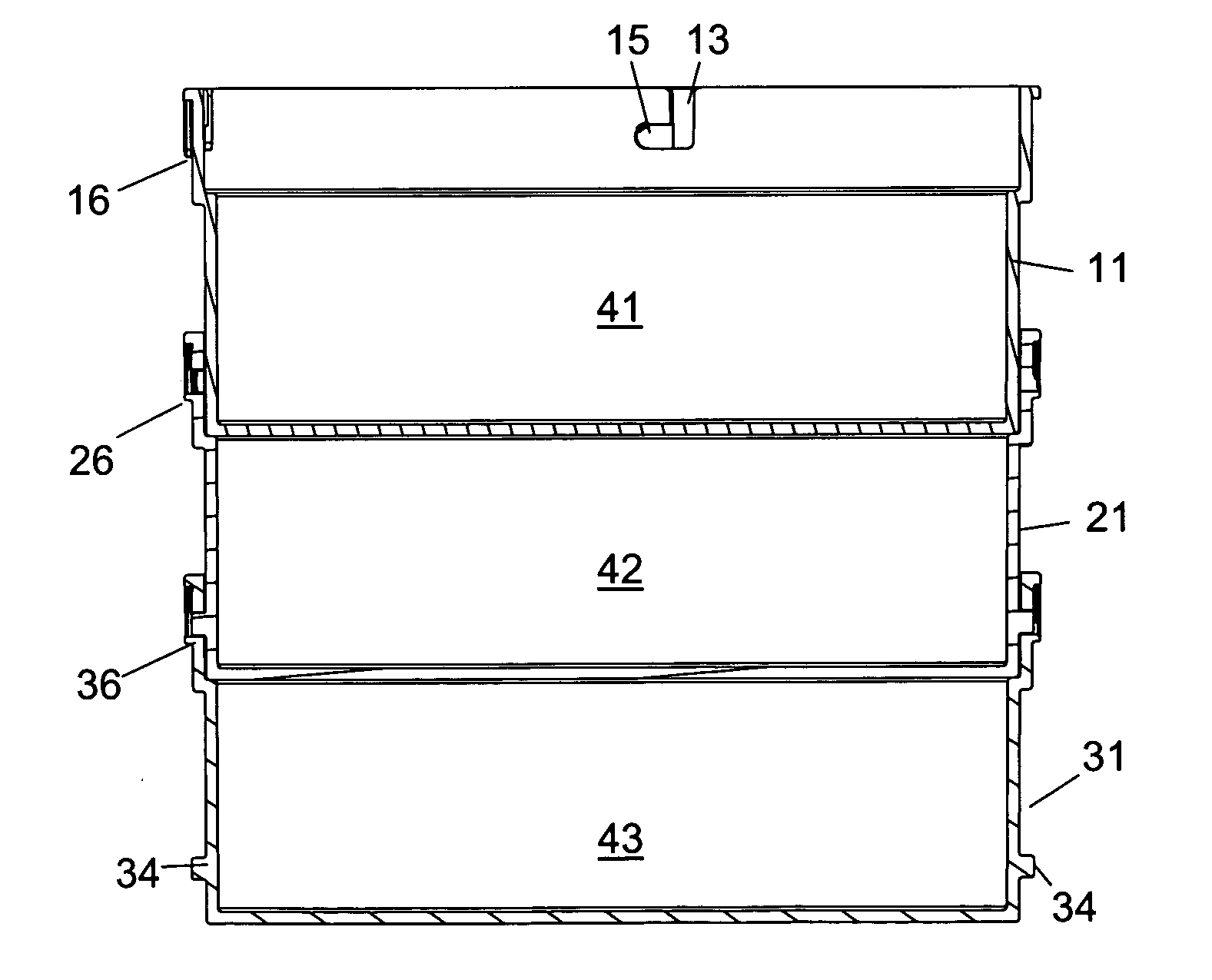

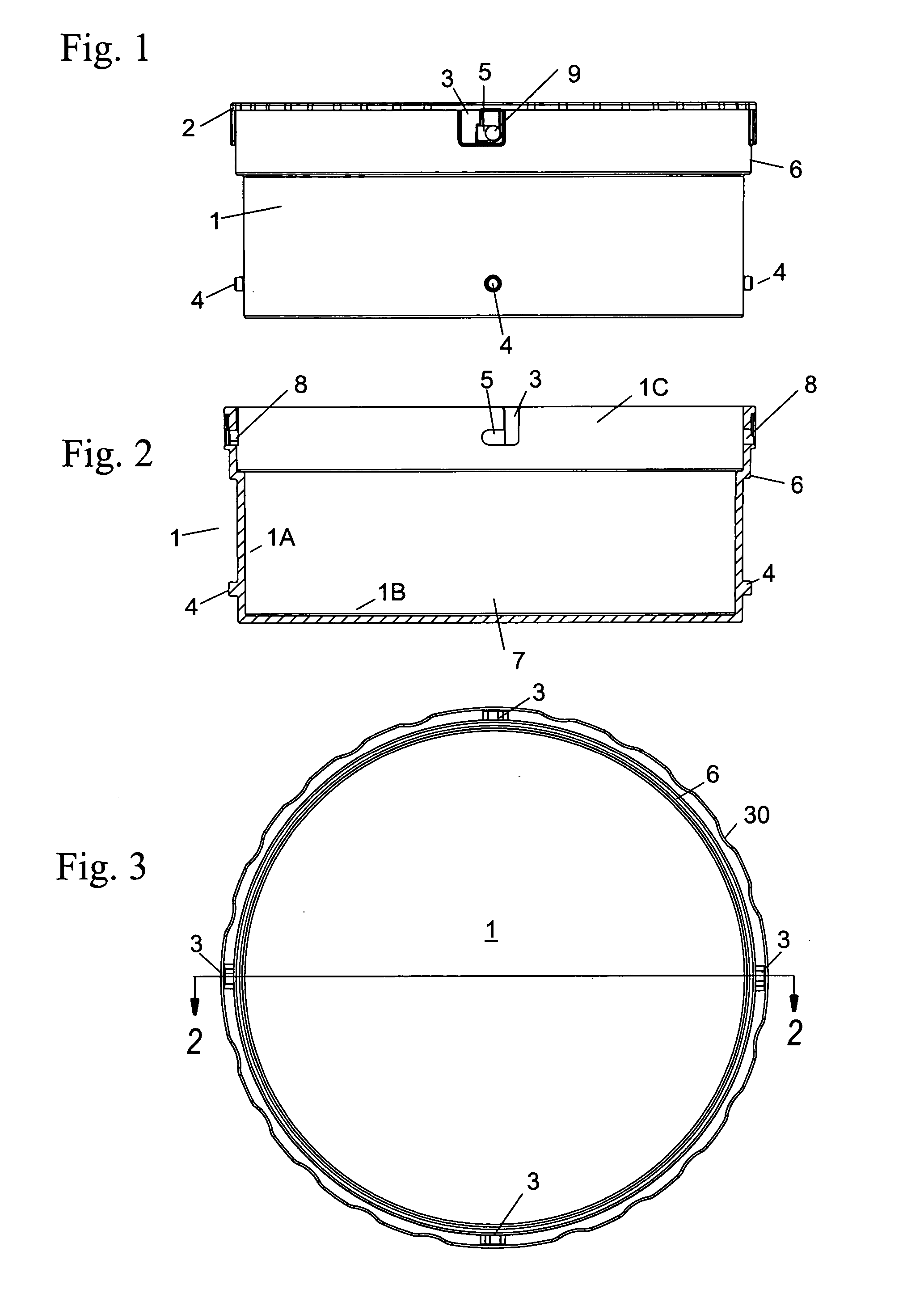

[0015] As illustrated in FIG. 1, my dough container storage system is based on a unique pan body 1 with a lid 2. As is usual with baking and rising pans, pan body 1 is defined by contiguous side walls 1A and a base 1B. Base 1B defines a bottom for pan body 1 with an open top 1C opposite therefrom. Pan body 1 also has a locking system with interfacing locking elements located on its exterior near its open top 1C and base 1B. This locking system allows pan body 1 to be connected to lid 2 and to other pan bodies in a stack. (See, e.g., pan bodies 11, 21, and 31 in FIGS. 4 and 5).

[0016] In the preferred embodiments illustrated, the interfacing locking elements of my locking system use a bayonet joint type drop and twist connection. This system is ideal for use with the type of round pan bodies 1, 11, 21, and 31 illustrated. It allows the base of the round pan body (e.g., base 1B of pan body 1) to be dropped into the open top of a lower pan body and rotated slightly to make a secure con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com