Sand-belt finishing machine having dust clearing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

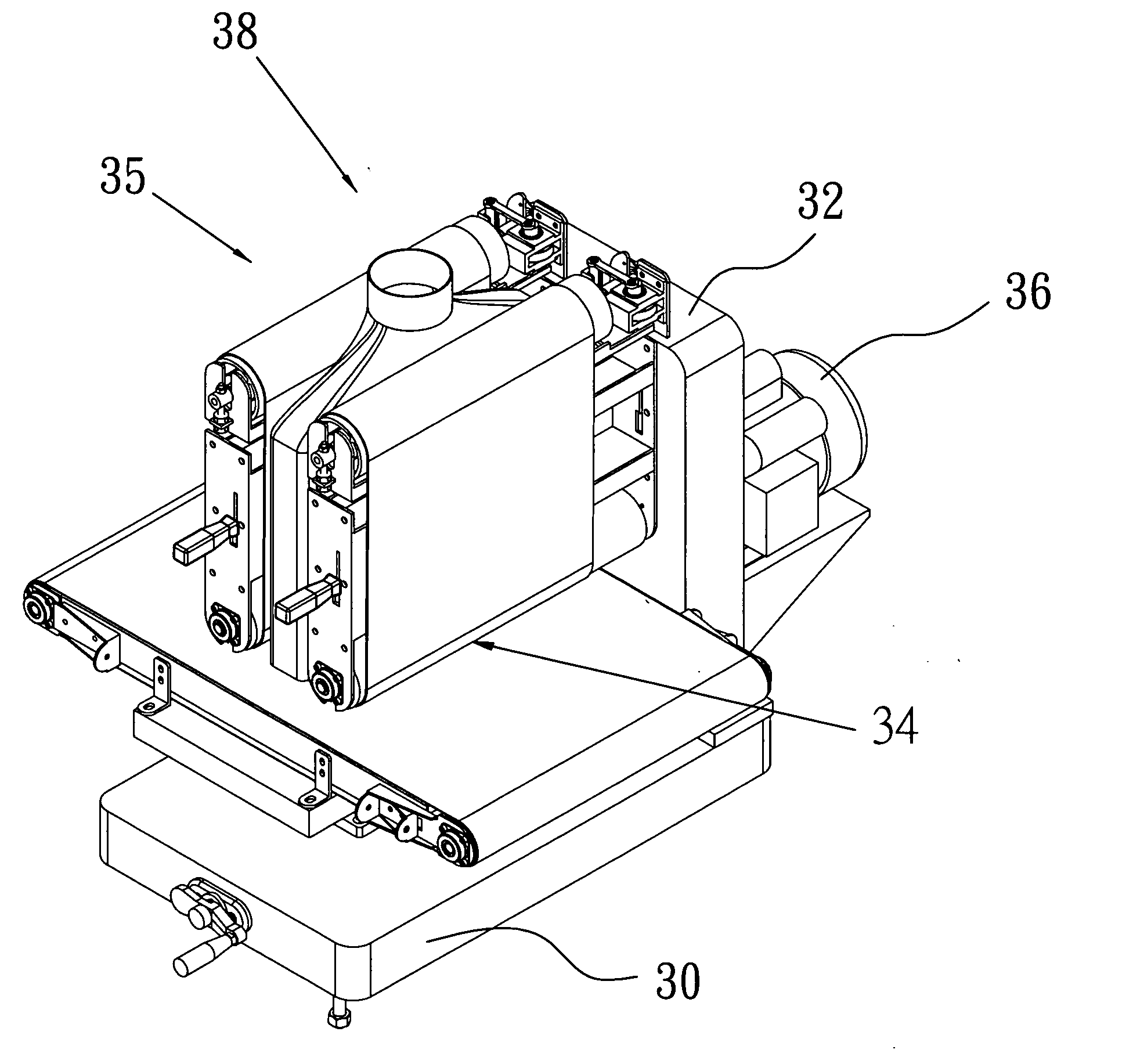

[0021] Referring to the drawings and initially to FIGS. 3 and 4, a sand-belt finishing machine in accordance with the preferred embodiment of the present invention comprises a main frame 30 disposed at a horizontal state, an upright seat 32 mounted on and vertical to the main frame 30, and two grinding devices 34 and 35 mounted on two sides of the upright seat 32.

[0022] The grinding device 34 includes two rollers 342 and 344 each located beside the upright seat 32, and a sand belt 346 reeved around the two rollers 342 and 344. The two rollers 342 and 344 of the grinding device 34 are spaced from each other and are mounted on the upright seat 32 in a parallel manner.

[0023] The grinding device 35 includes two rollers 352 and 354 each located beside the upright seat 32, and a sand belt 356 reeved around the two rollers 352 and 354. The two rollers 352 and 354 of the grinding device 35 are spaced from each other and are mounted on the upright seat 32 in a parallel manner.

[0024] Prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com