Method and apparatus for removal of grease, smoke and odor from exhaust systems

a technology of exhaust system and exhaust fume, applied in the direction of lighting and heating equipment, heating types, domestic stoves or ranges, etc., to achieve the effect of improving contaminant extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

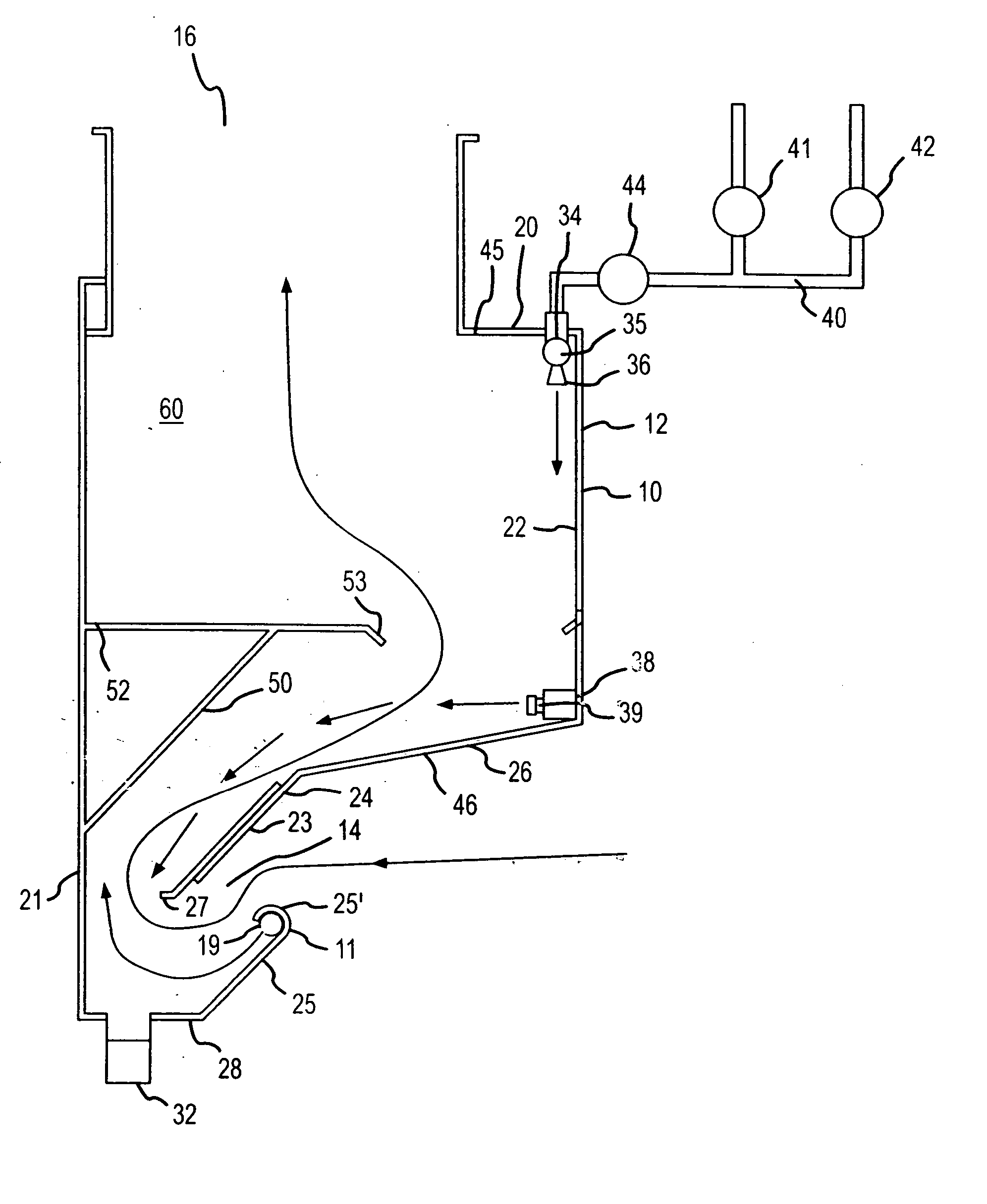

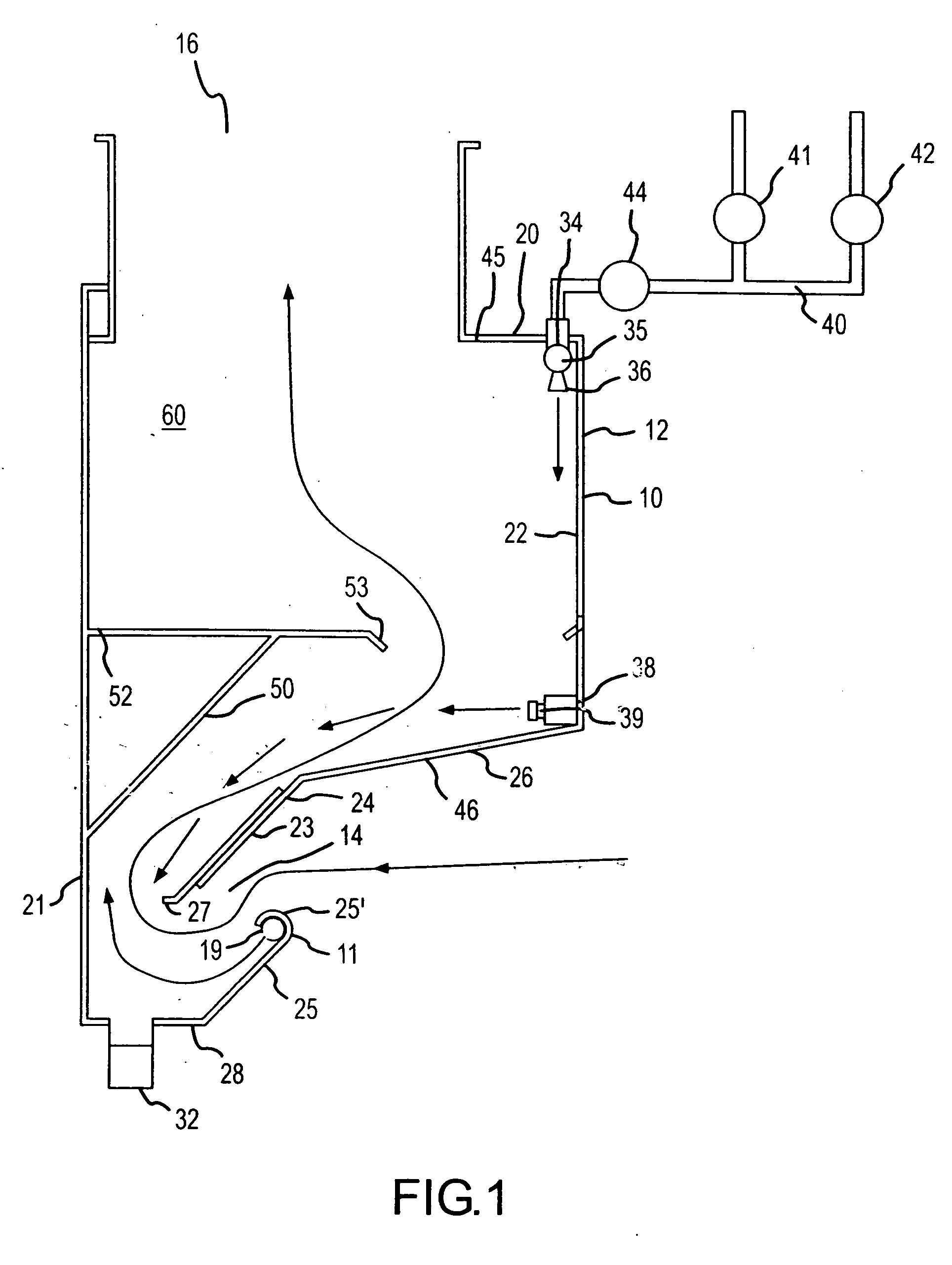

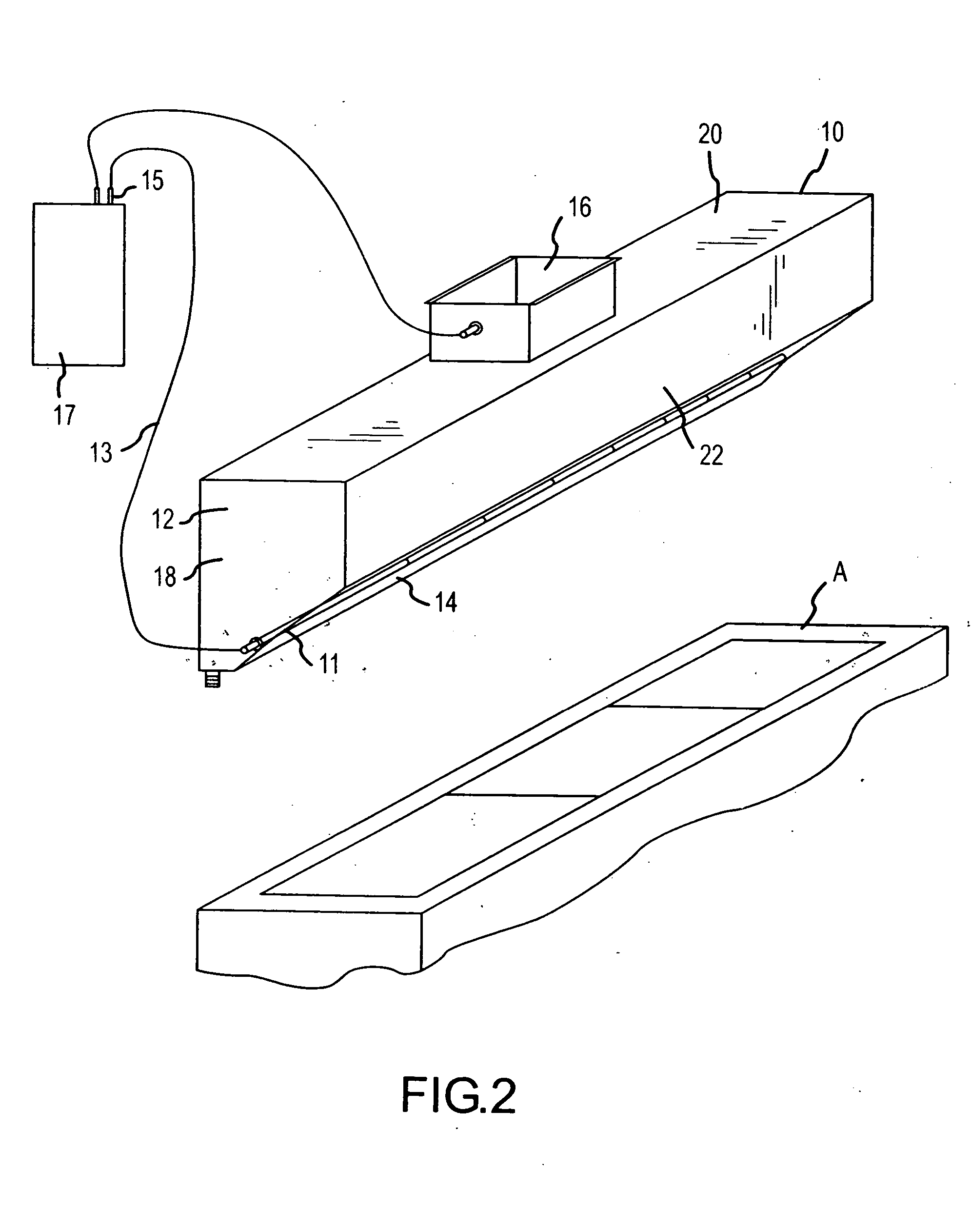

[0021] Referring in more detail to the drawings, specifically FIGS. 1 and 2, a preferred form of ventilator apparatus 10 is installed in a conventional manner above a cooking appliance A and is made up broadly of a hood or housing 12 having a lower inlet passage area 14 and an upper exhaust duct 16. In a well-known manner, the exhaust duct or collar 16 is connected into the flue of a chimney or other exhaust system available in the building, which typically includes an exhaust fan downstream of the exhaust duct 16, to induce the upward and outward flow of vapors and contaminants generated by the cooking appliance through the air inlet passage 14.

[0022] In one form, the hood 12 is of generally rectangular configuration and elongated to traverse the substantial width of the cooking appliance and with the air inlet passage centered in spaced relation above the appliance. As further shown in FIGS. 1 and 2, the exterior of the hood 12 includes opposite end walls 18, a top horizontal wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com