Garment with subpanel ventilation assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

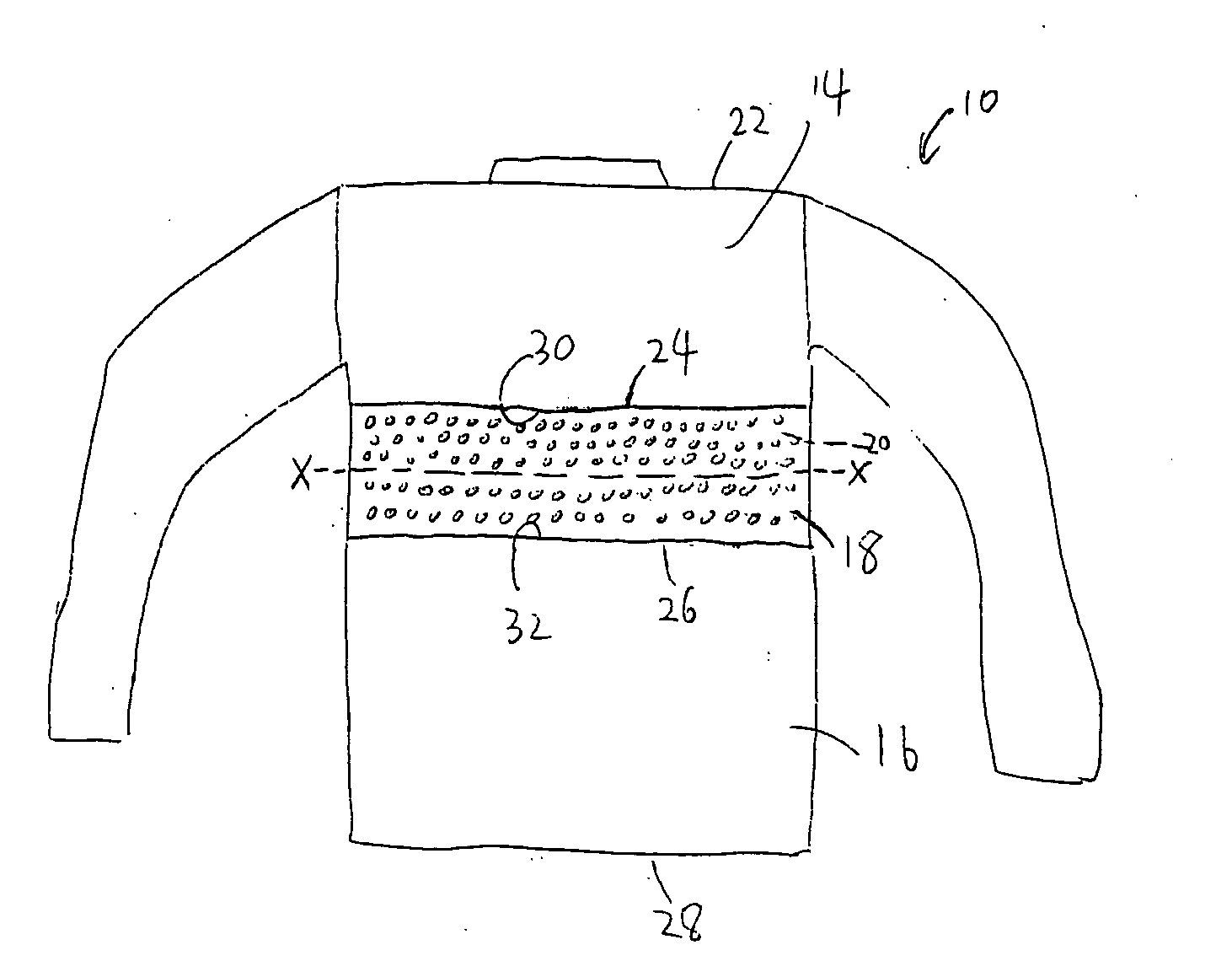

[0022]FIG. 1 shows a front view of a panel 12 designed with a ventilating assembly in accordance with the present invention, which is used as a back panel of a jacket. According to one preferred embodiment of the present invention, the panel 12 includes an upper air impervious panel 14, a lower air impervious panel 16, an air permeable vent panel 18 positioned between the upper air impervious panel 14 and the lower air impervious panel 16 and joining the two air impervious panels 14 and 16 together, and an air impervious underlay panel 20 underlying and spanning the vent panel 18.

[0023] According to one aspect of the present invention, the upper air impervious panel 14 includes two opposing edges, a top edge 22 and a bottom edge 24. The lower air impervious panel 16 also includes two opposing edges, a top edge 26 and a bottom edge 28. The air permeable vent panel 18 extends along a vent axis X, and also includes a top edge 30 and a bottom edge 32 on either side of the vent axis X. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com