Multi-lens hydrogen, electric and steam power plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

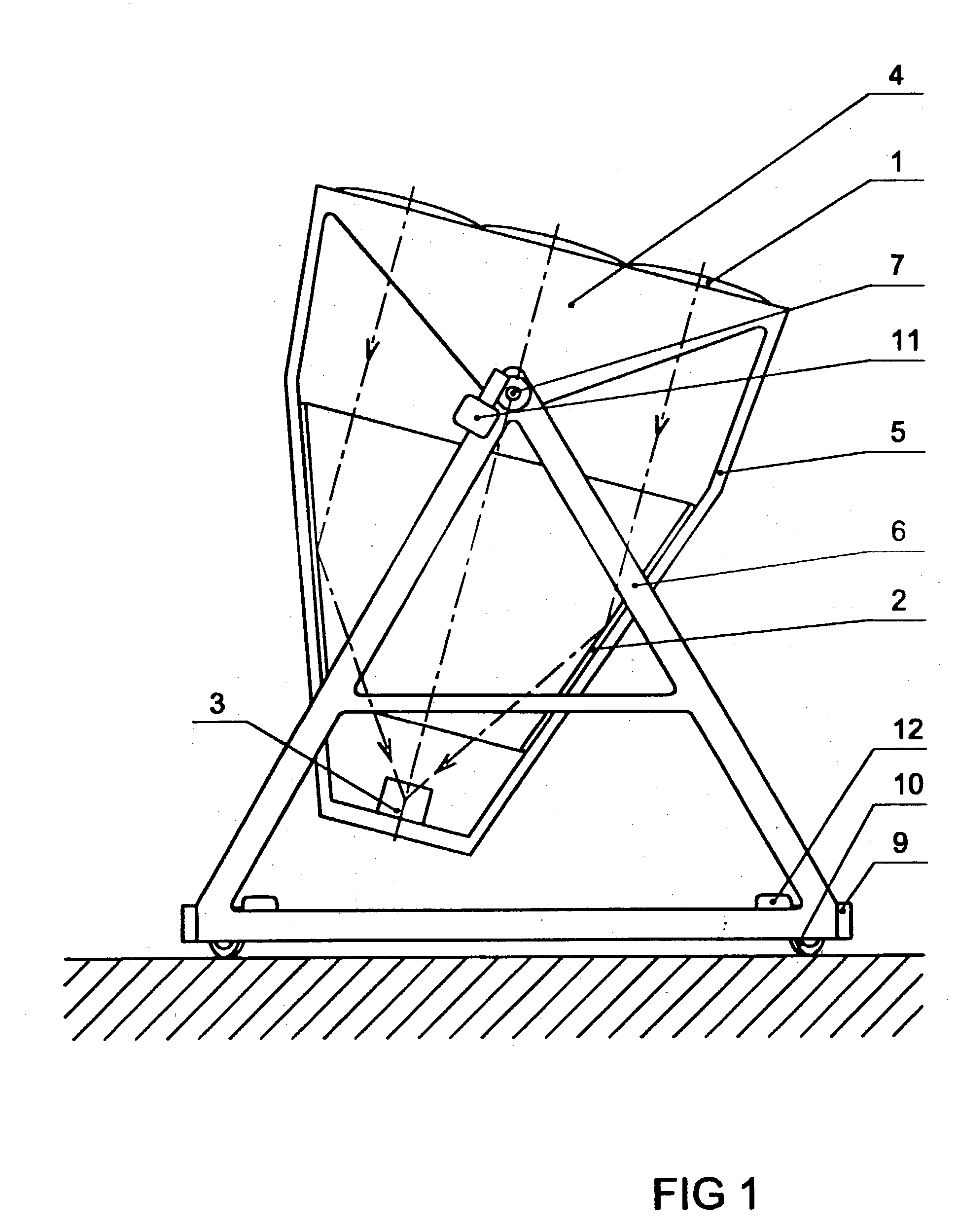

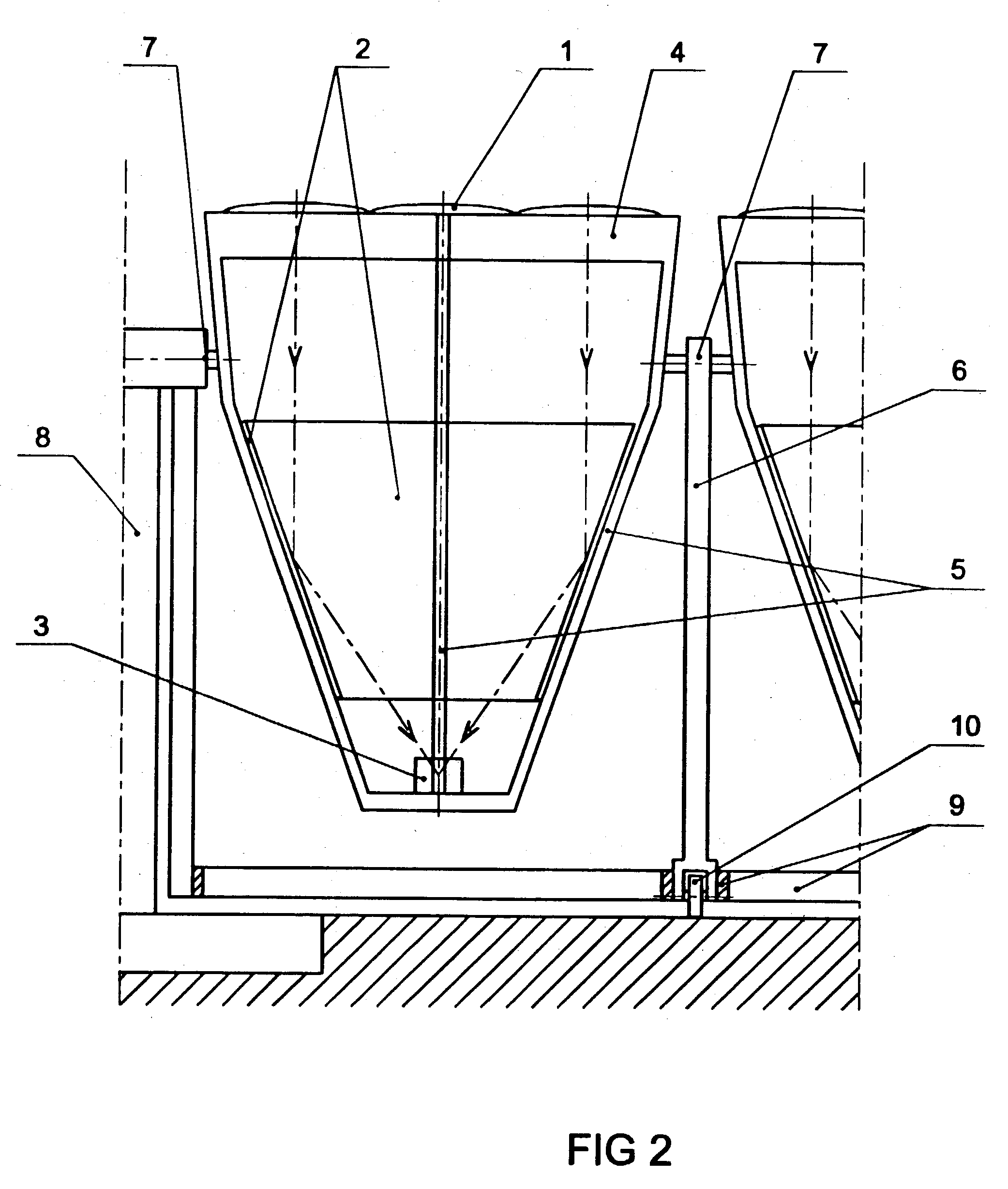

[0019] In a hydrogen power plant there are pillow lenses 1, diameter 1.8 meters. In a frame 4 there is a group of nine lenses. In the focal point there is an apparatus 3 where a ceramic water splitter is placed. In an electric / steam power plant there are, accordingly, 0.6-meter lenses, and the focal point apparatus 3 is provided with a vaporiser. Flat mirrors 2 reflect ray bundles from eight lenses into the apparatus 3 placed in the focal point of the ninth lens, which is in the middle of the group.

[0020] In a hydrogen power plant there are 2.times.12 frames and in an electric / steam power plant 6.times.36 frames side by side. The lens surfaces have a height of 10.8 meters, a length of 64.8 meters and an area of about 700 square. The effective output is about 400 kW.

[0021] In the middle of each frame 4 there is a column 8 provided with a bearing housing. The frames are mounted onto the columns and bases 6 by means of bearings 7. In vertical direction, the frames 4 are turned towards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com