Liquid droplet ejecting apparatus

a technology of ejecting apparatus and liquid droplets, which is applied in the direction of typewriters, printing apparatus, printing, etc., can solve the problems of ink spraying into the air, inadvertent ejecting of ink in unintended situations, and undesired pollution of the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

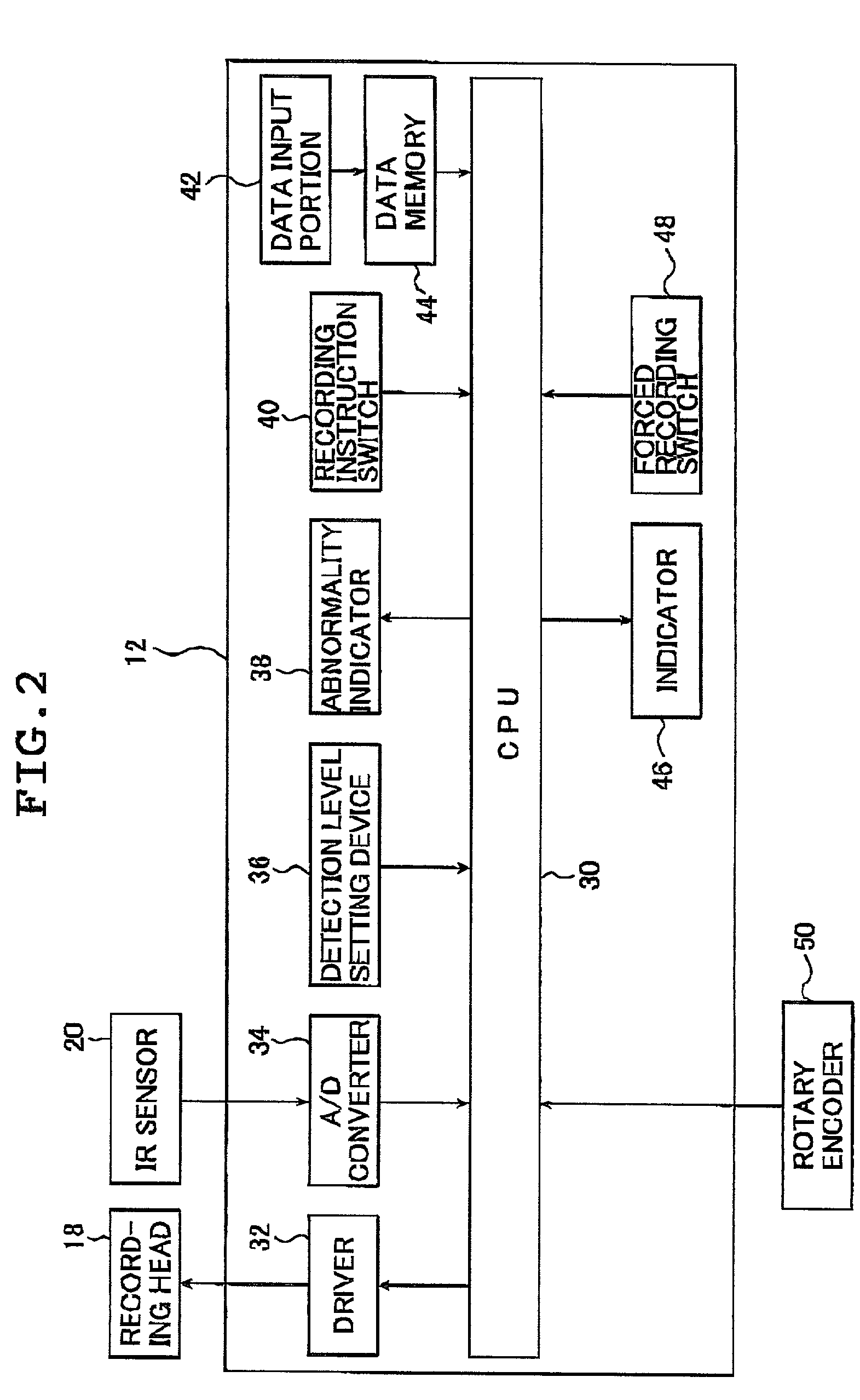

[0027] Preferred embodiments of the liquid droplet ejecting apparatus of the present invention will now be described in detail with reference to the accompanying drawings.

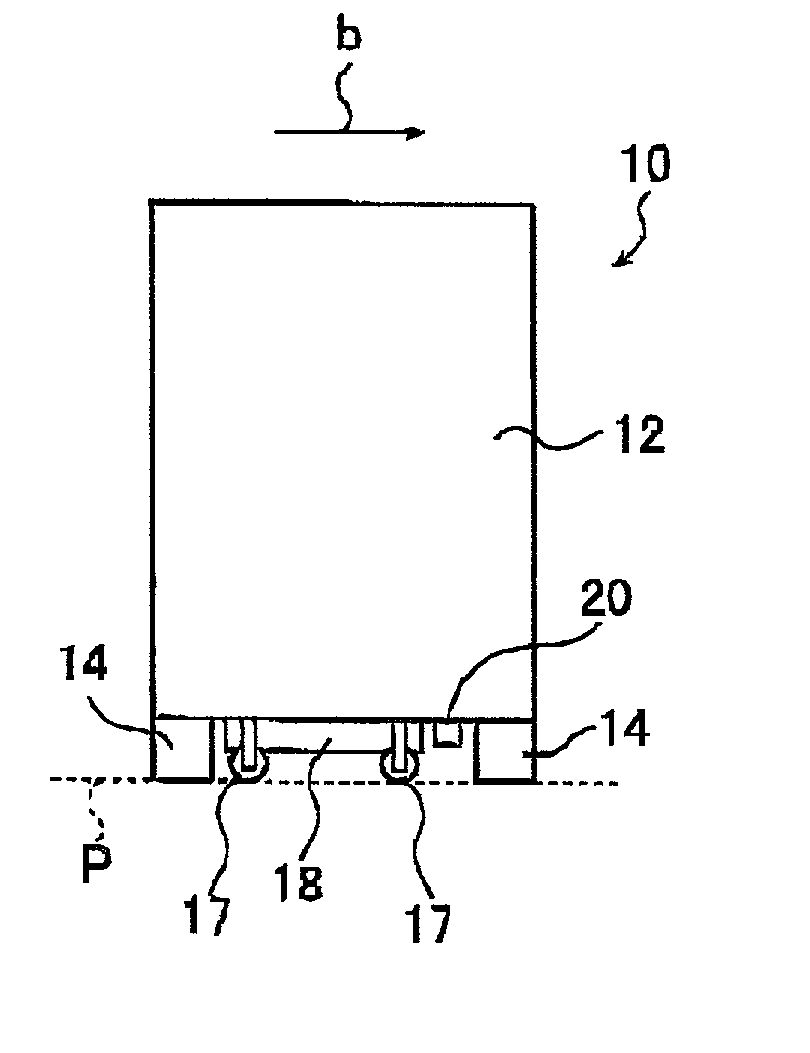

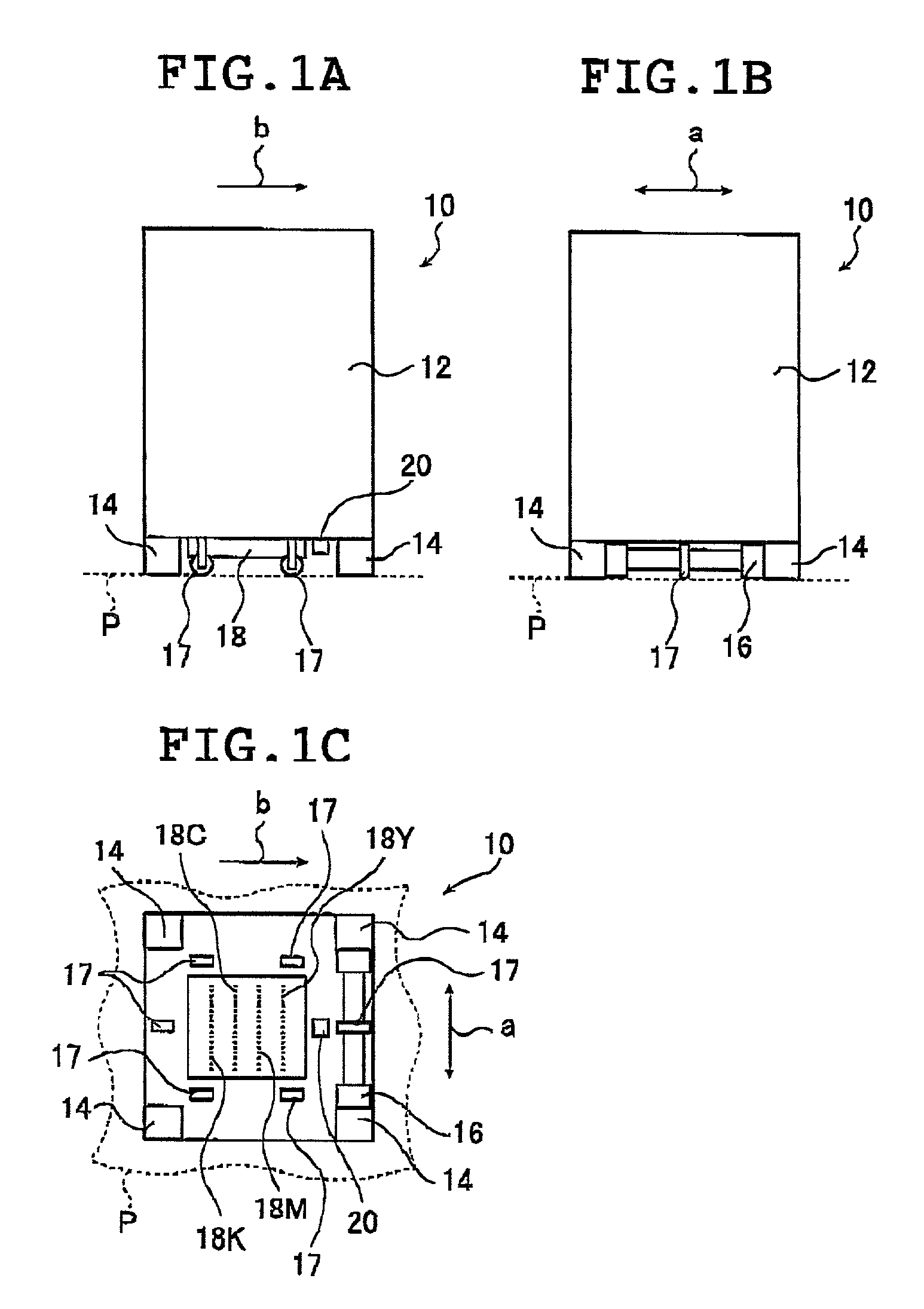

[0028] FIGS. 1A, 1B, and 1C are conceptual drawings showing an embodiment of an ink jet printer utilizing the liquid droplet ejecting apparatus of the present invention. FIGS. 1A is a side view (as seen from the direction of the nozzle row described below), FIG. 1B is a front view (as seen from the direction of scanning described below), and FIG. 1C is a bottom view (as seen from the image receiving sheet).

[0029] The ink jet printer (hereinafter referred to as printer) 10 shown in FIGS. 1A, 1B, and 1C basically comprises a main body 12, leg portions 14, rollers 16, auxiliary wheels 17, an ink jet recording head (hereinafter referred to as recording head) 18, and an IR (infrared rays) sensor 20.

[0030] The printer 10 records images an a recording medium other than a human body (a recording sheet P in the example show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com