Pump protection system

a protection system and pump technology, applied in drinking water installation, borehole/well accessories, construction, etc., can solve the problems of affecting the production of methane, affecting the quality of methane,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

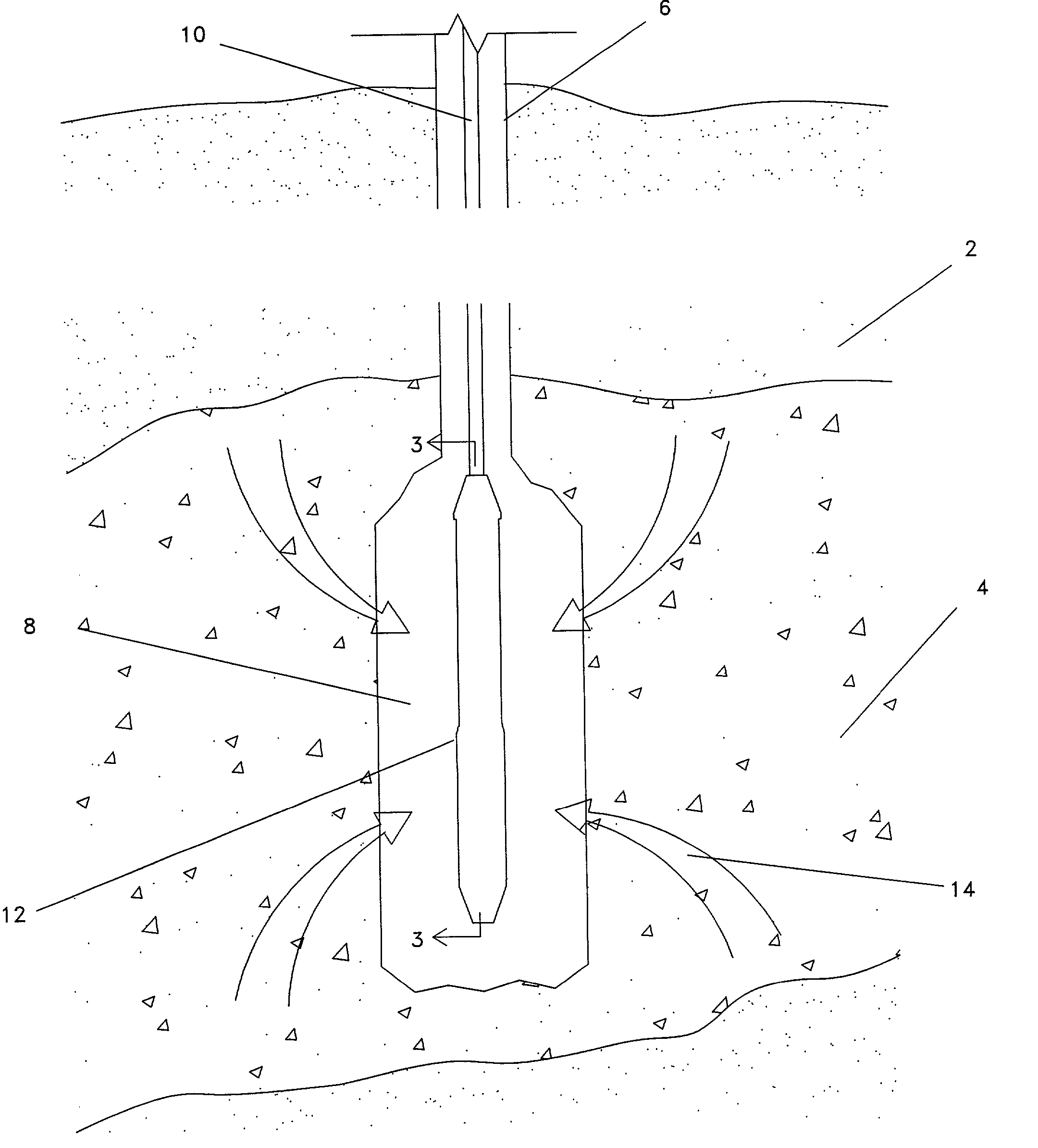

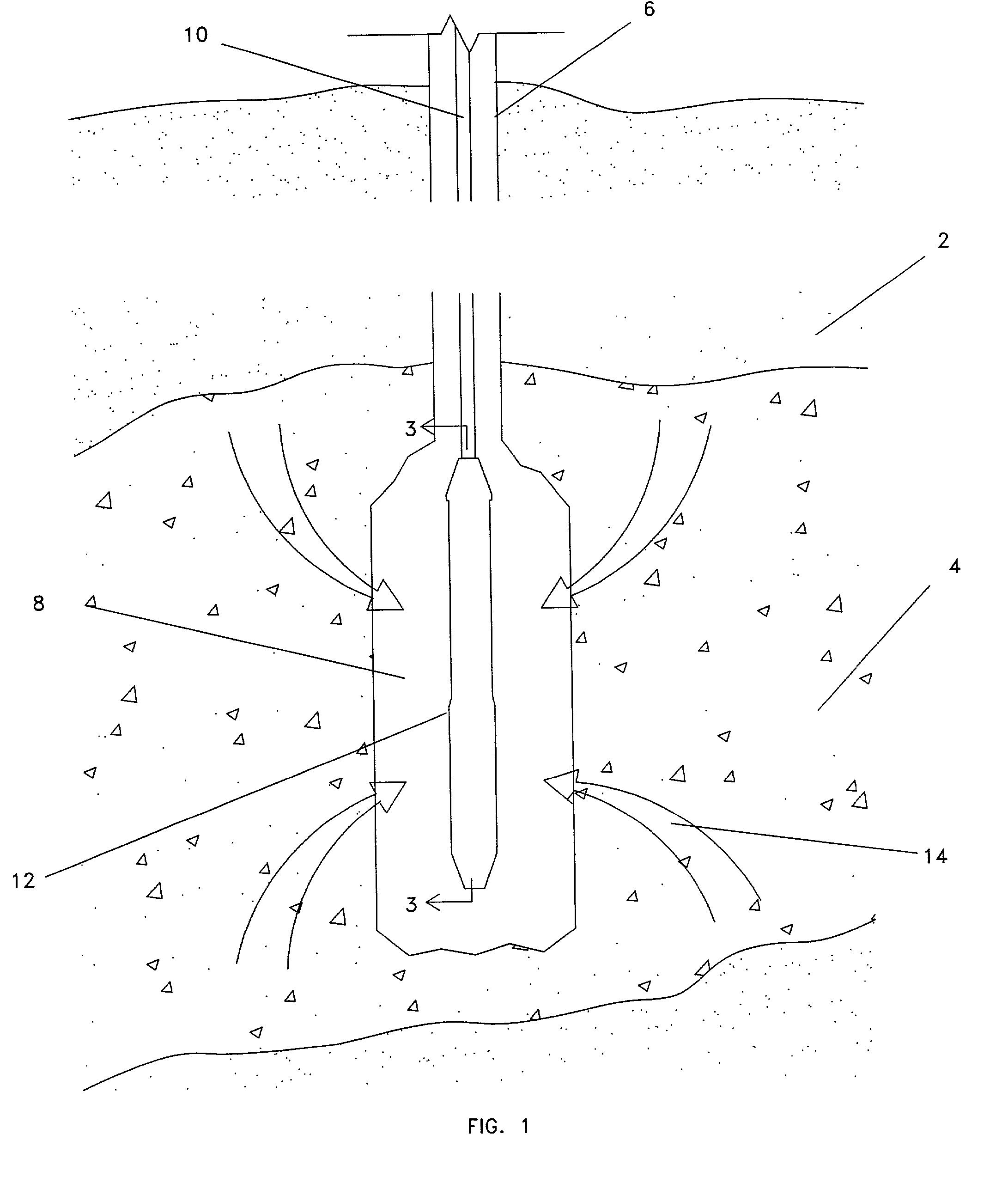

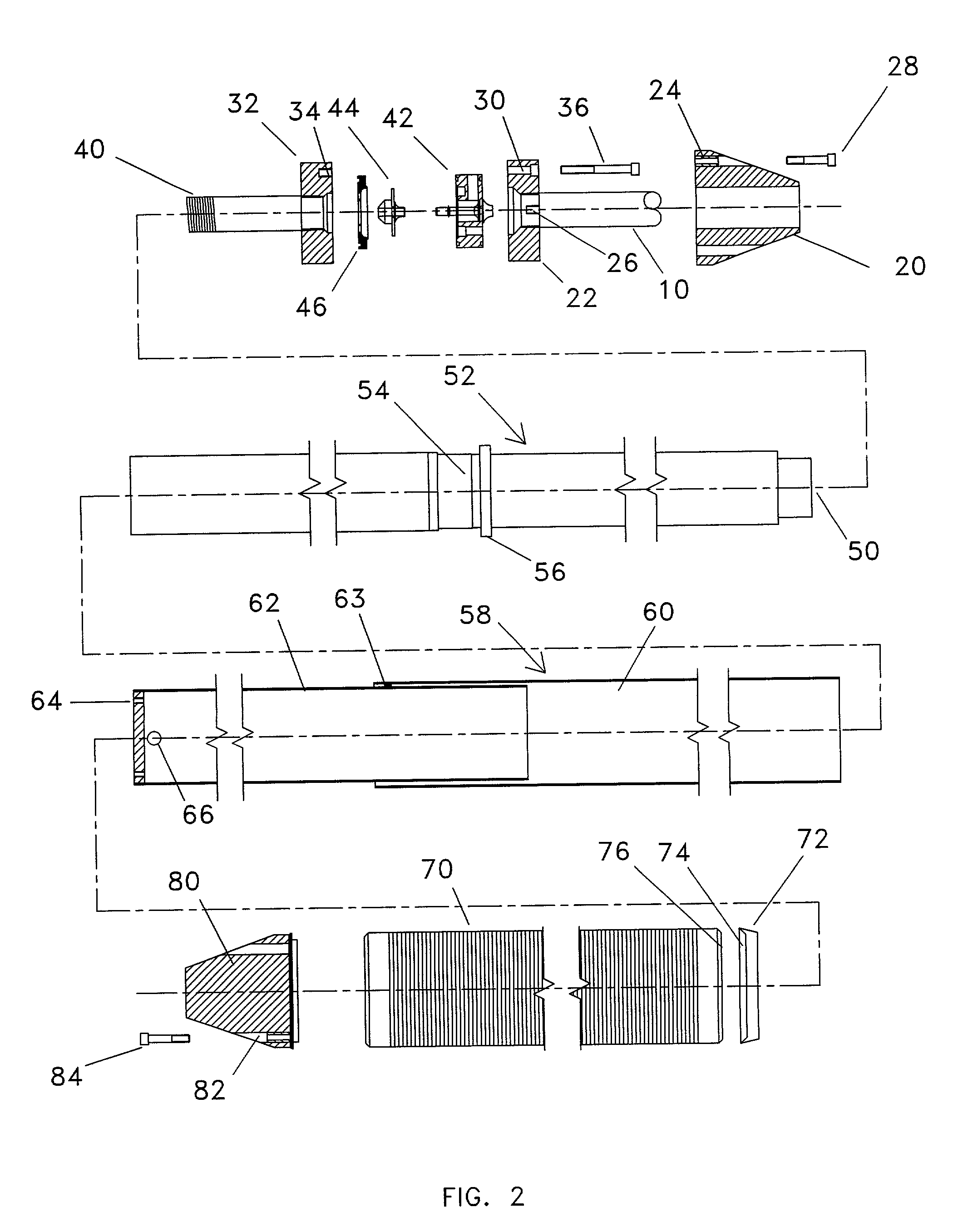

[0037] Referring to the drawings, FIGS. 1 through 5B and 7, there is shown a preferred form of the pump protection system embodying the present invention. The pump protection system of the instant invention may be used to prevent clogging, promote cooling, and self-clean any pumping system in which the pumping system includes a pump intake port which is susceptible to being clogged by unwanted solid particles.

[0038] Referring to FIG. 1, a side view of a well pumping system including the pump protection system of the instant invention is shown. Although the pump protection system could be used in a variety of situations, the system depicted in FIG. 1 will be used for a description of a preferred embodiment of the instant invention. Area 2 depicts any type of underground composition. Coal seam 4 depicts a coal seam within area 2 which is porous and permeable and contains water and methane. Well casing 6 is an enclosed section (usually by some type of pipe) which runs from the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com