Temporary guard rail system

a guard rail and rail system technology, applied in the direction of fencing, building material handling, construction, etc., to achieve the effect of convenient installation, high efficiency and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

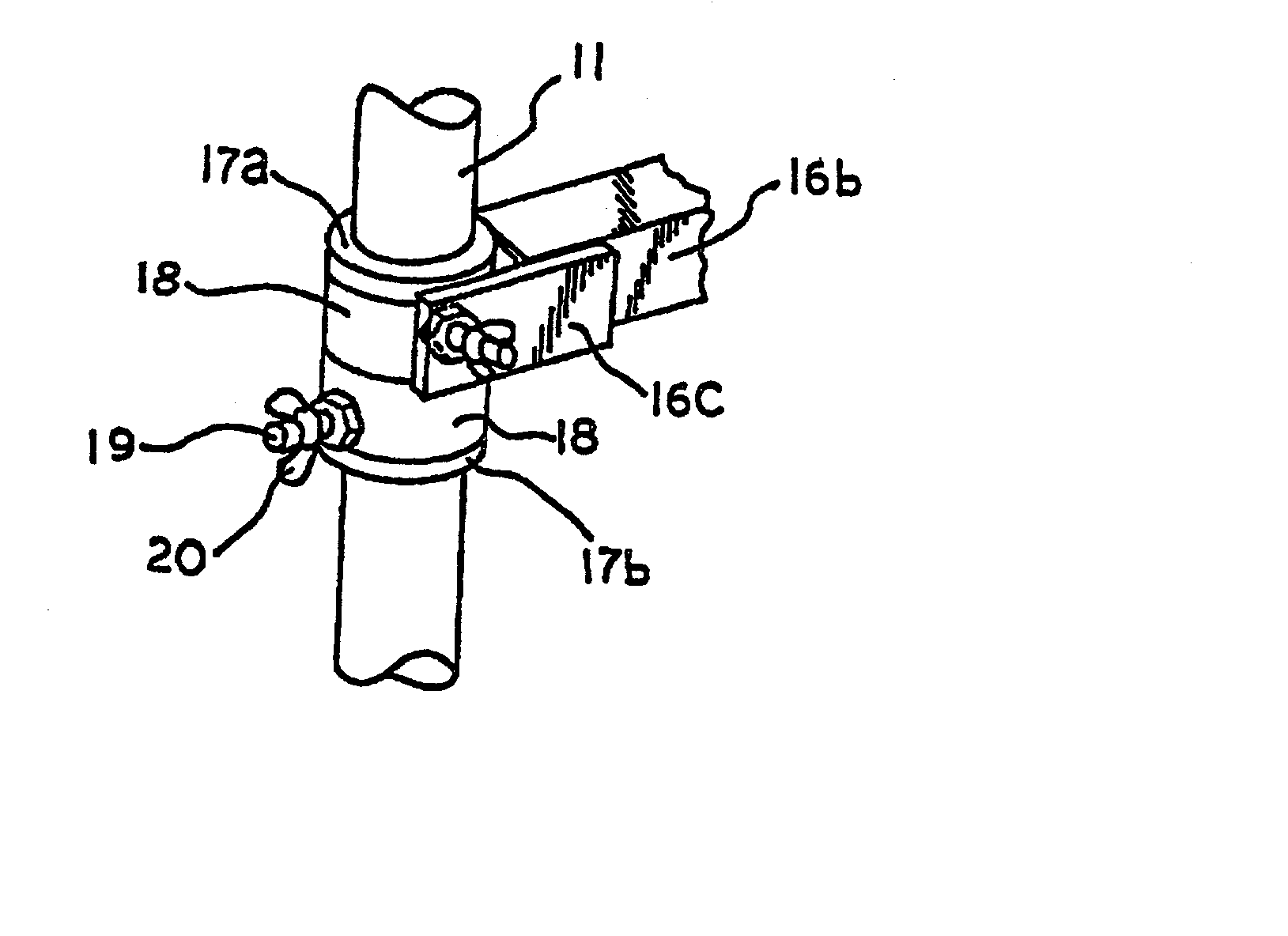

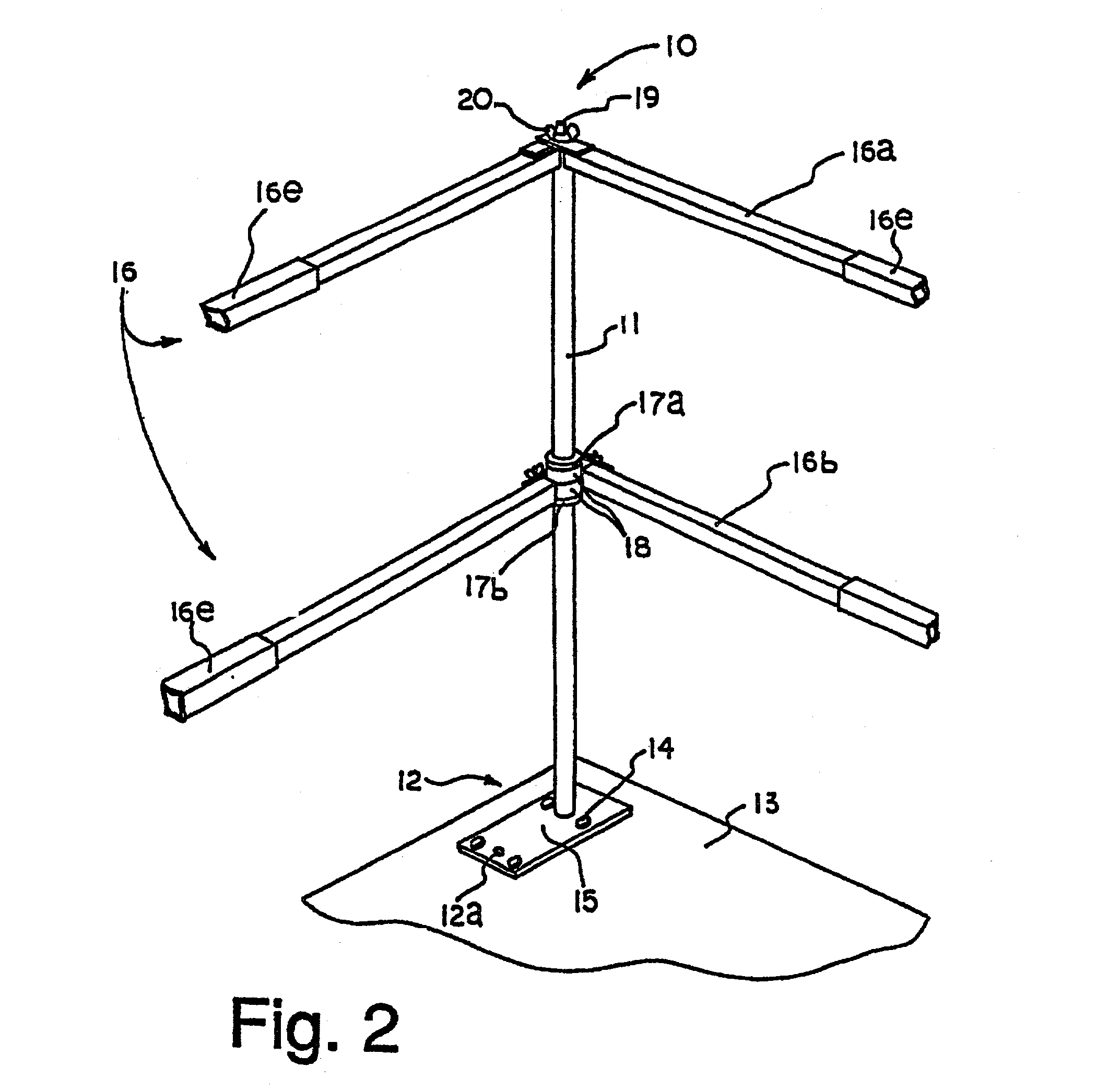

[0040] With further reference to the drawings, the temporary guard rail system in accordance with the present invention is illustrated in FIG. 2 and indicated generally at 10. The temporary guard rail system 10 comprises a plurality of upright stanchions 11 as shown in FIG. 1. In the preferred embodiment, stanchions 11 are formed from solid steel bars in order to comply with OSHA strength regulations. However, it will be appreciated that other materials such as aluminum, fiberglass and similar composites may be utilized in alternative embodiments.

[0041] The lower end of each stanchion 11 has integrally formed therewith or otherwise fixed thereto an anchor bracket, indicated generally at 12, for attaching each stanchion 11 to the building subfloor 13 or other suitable forming members (not shown). In the preferred embodiment, stanchion 11 is positioned in a predetermined location on anchor bracket 12 and is attached in perpendicular relation thereto by weldment or other suitable means...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com