Display panel filter for connection to a display panel

a technology for filtering and display panels, applied in the direction of identification means, television systems, instruments, etc., can solve the problems of electromagnetic interference (emi) emissions, the depth dimension of display requires a significant amount, and new problems have arisen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention relates to a plasma display panel filter, or shielding film for use therein, which functions to provide EMI and IR shielding capabilities. Preferably the filter also provides anti-reflective (AR) capability. Various features of the present invention have possible application other than for display panel filters. However, the description of the preferred embodiment will be for use in a plasma display panel filter.

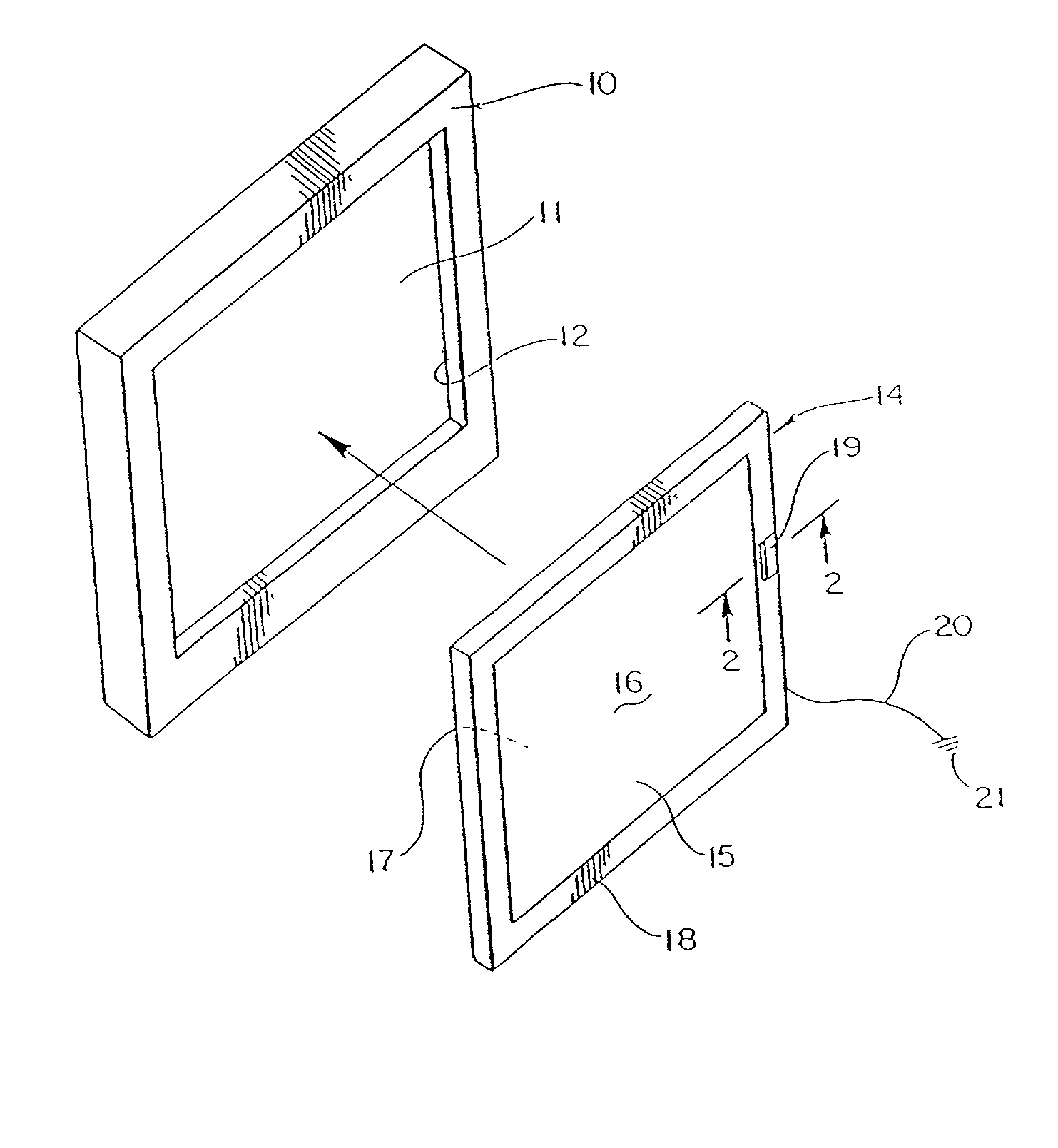

[0034] Reference is first made to FIG. 1 illustrating an exploded, isometric view of a plasma display panel 10 and associated filter 14 in accordance with the present invention. The display panel 10 as illustrated in FIG. 1 in accordance with the preferred embodiment is a generally rectangular configured device having a front viewing or display screen 11 and a recessed area 12 for receiving a display panel filter 14. It should be understood, however, that the possible relationships between a plasma display panel and a filter in accordance with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com