Method for producing an engineered wood board and engineered wood board production installation

a technology of engineered wood and production installation, which is applied in the direction of lignocellulosic moulding material treatment, domestic articles, flat articles, etc., can solve the problems of complex visual detection of vapour distribution and is almost impossible to automate, and achieves fast recognition, reliable, and inhomogeneity monitoring of applied fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

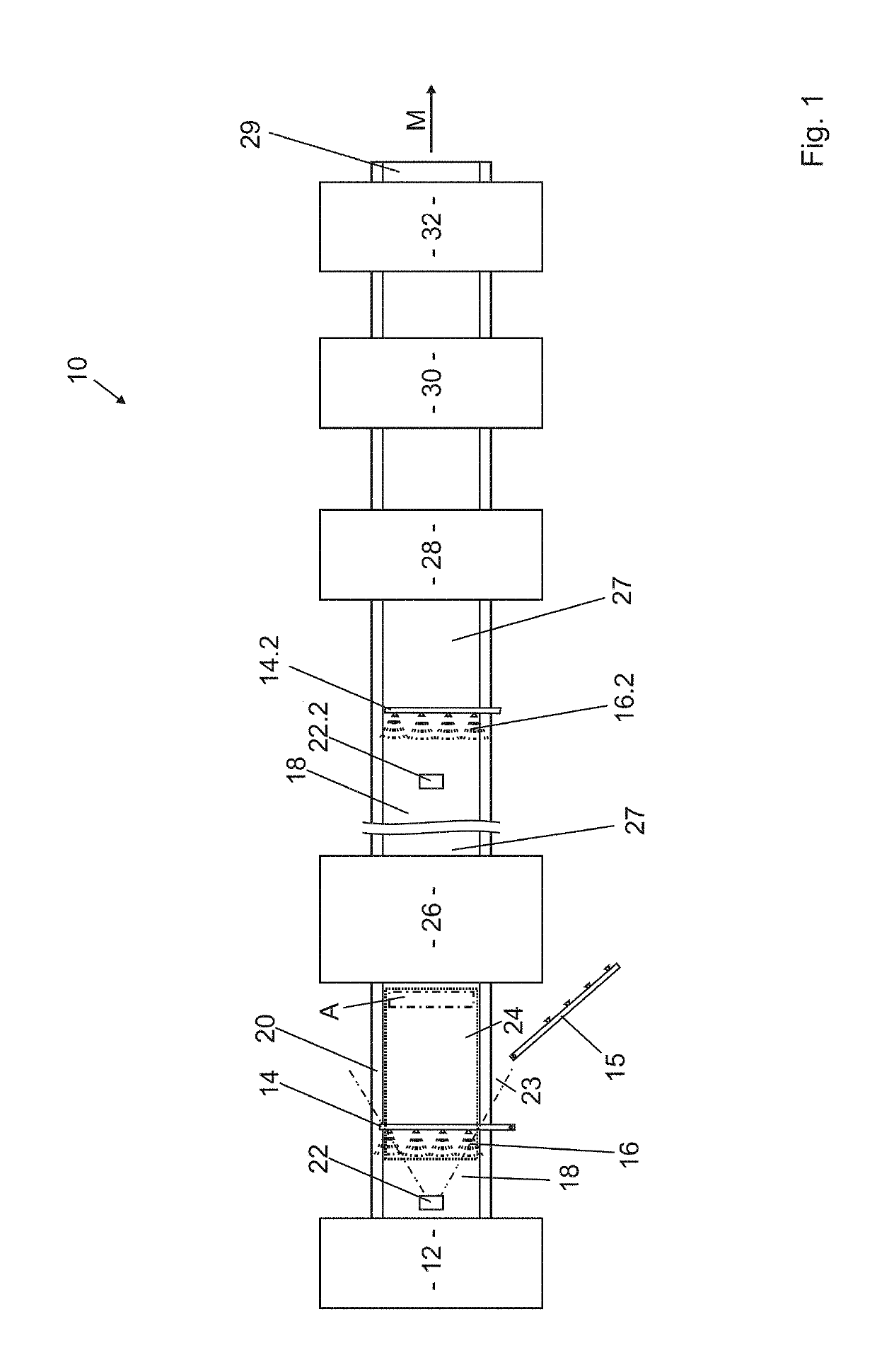

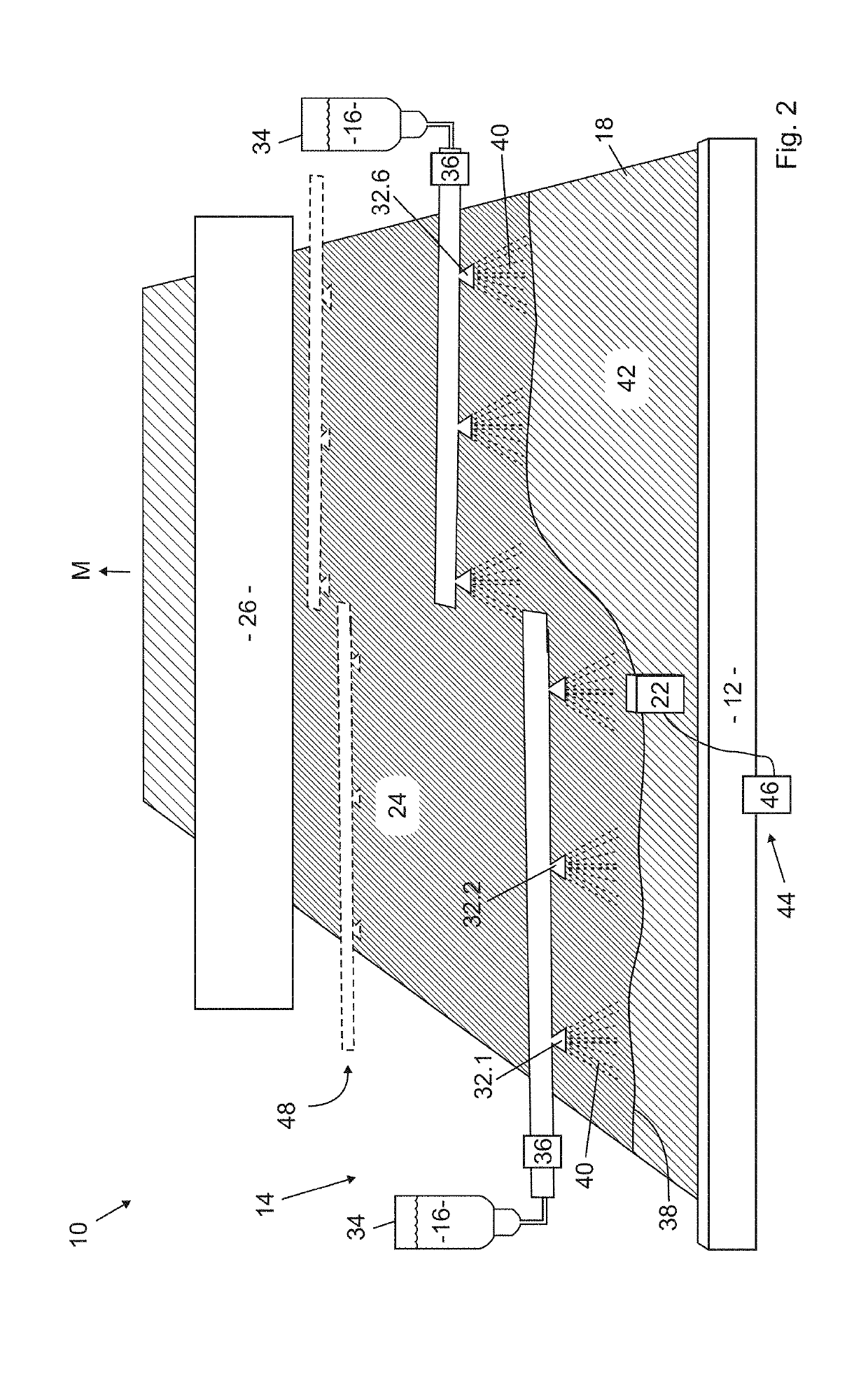

[0058]FIG. 1 schematically depicts an engineered wood board production installation 10 that comprises a substrate production installation 12 and an applicator 14 for applying a fluid 16 to a substrate 18. At this point the substrate 18 is a pressed fibre mat and is produced by the substrate production installation 12 by scattering wood fibres that have been coated in an adhesive onto a conveyor 20.

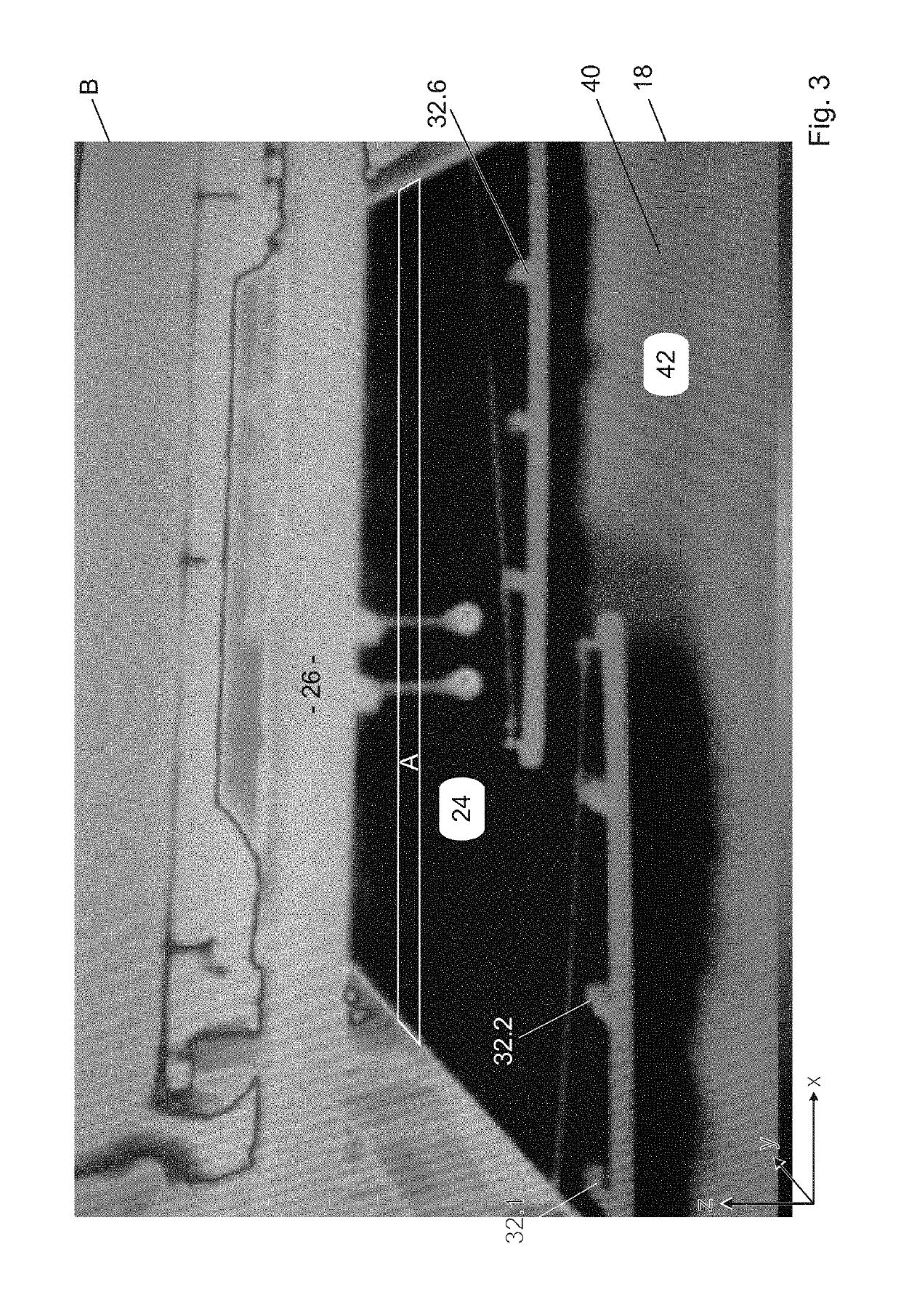

[0059]The engineered wood board production installation 10 comprises an infra-red camera 22 in whose field of vision 23 an application area 24 lies. The application area 24 is the area of the substrate 18 that is moistened with fluid 16. A press 26 is arranged in a material flow direction behind the applicator, which presses the pressed fibre mat 18 to form an engineered wood board 27. The press 26 is a double belt press having two belts made from stainless steel that are

[0060]A cutting device may be provided behind the press 26 in the material flow direction M that cuts the resulting engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com