Method for monitoring resistant current in leakage current of an arrester

A technology of resistive current and leakage current, applied in the direction of measuring current/voltage, measuring electrical variables, instruments, etc., can solve problems such as insensitivity, error of measurement results, offset, etc., and achieve the effect of improving reliability and avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

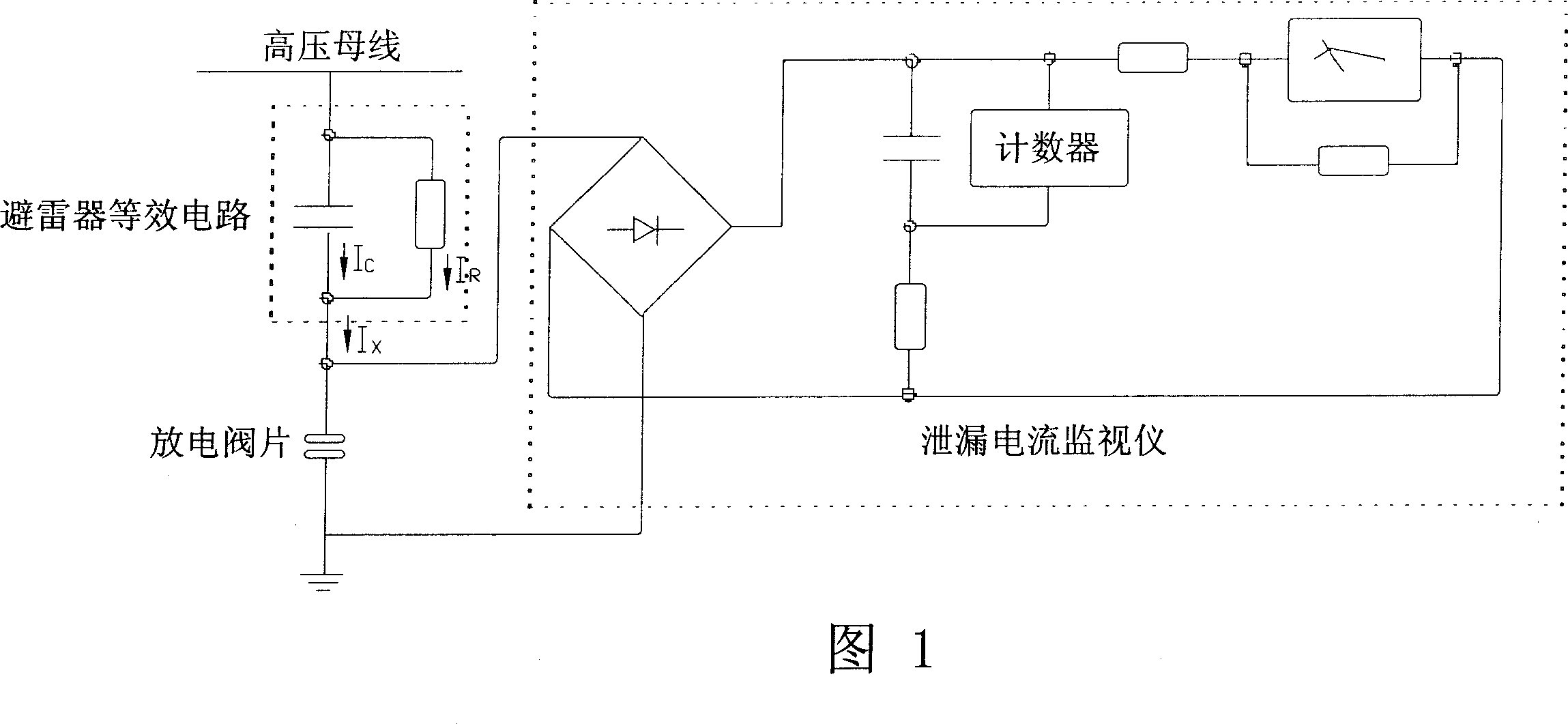

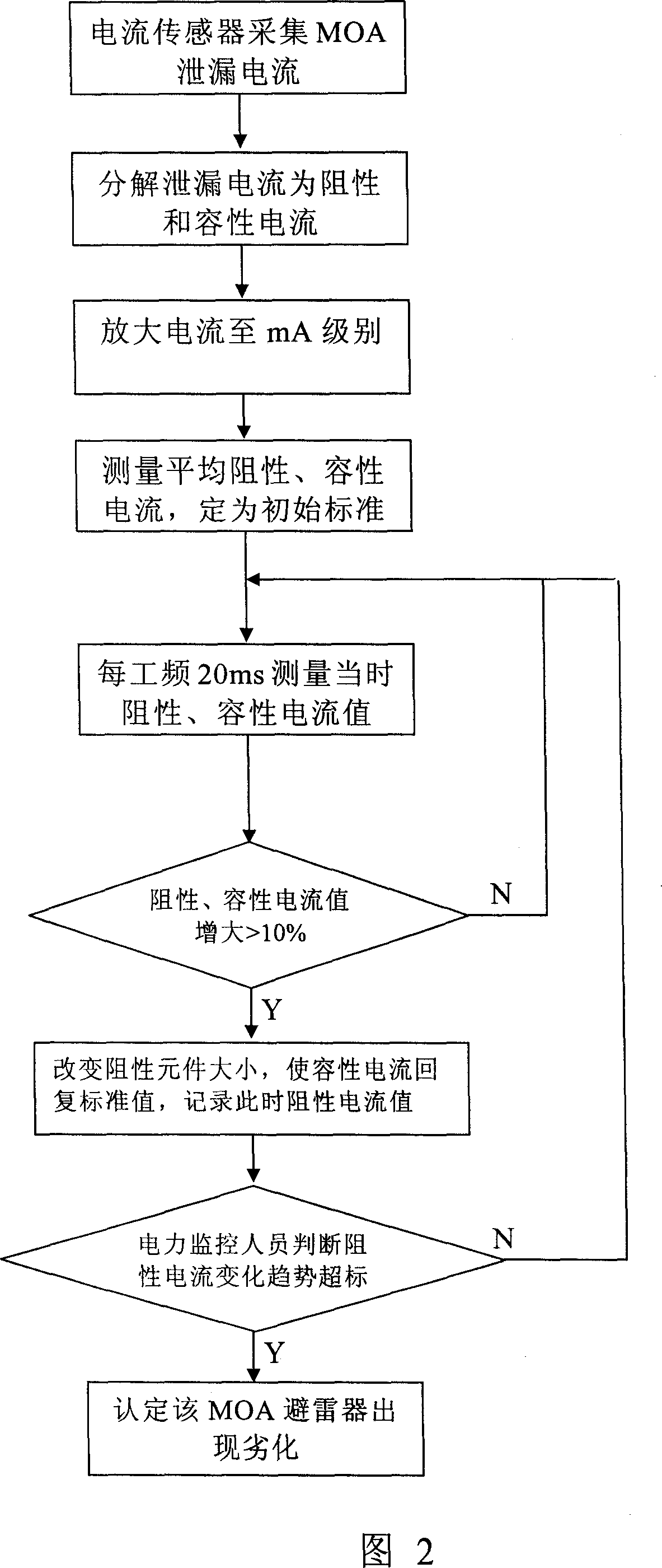

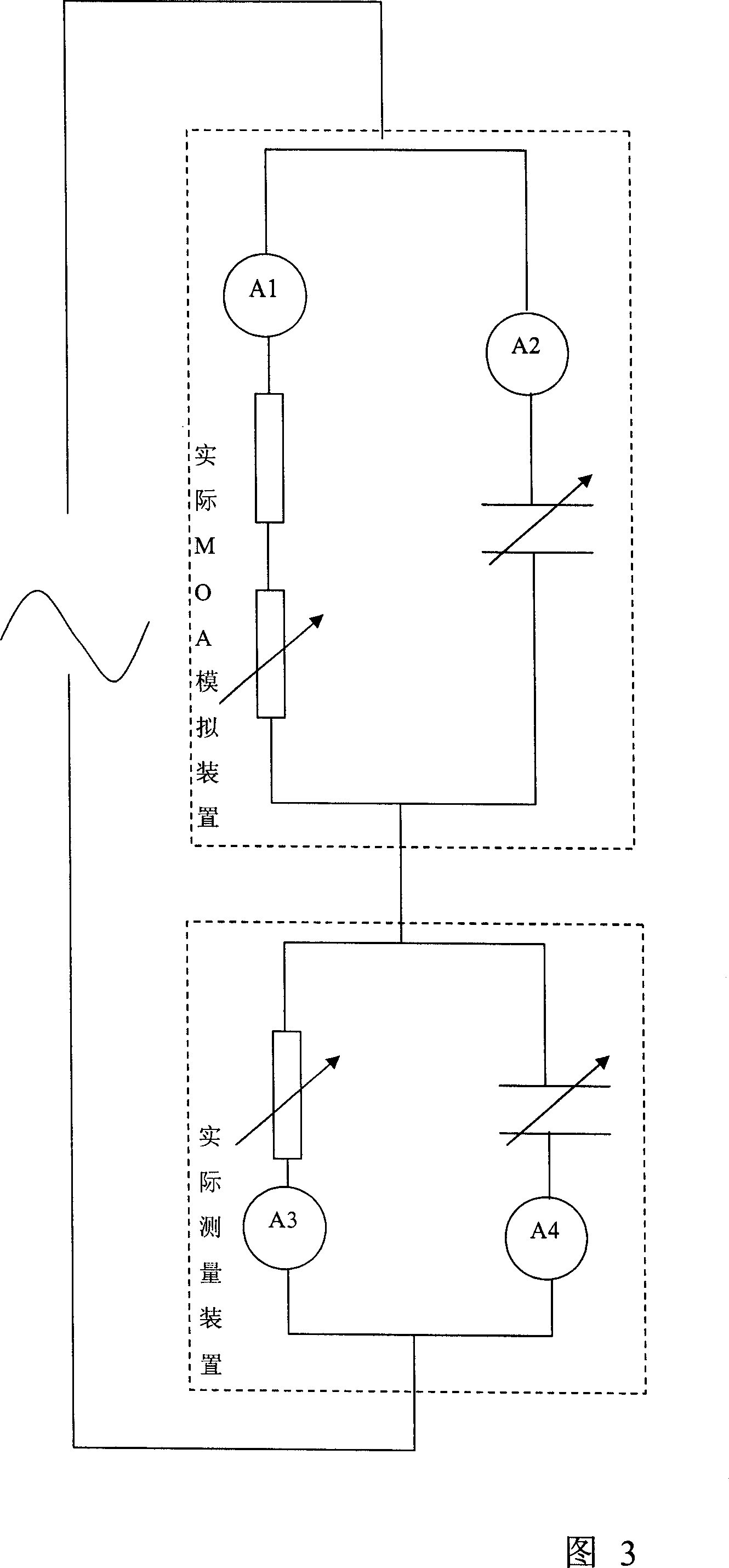

[0025] The present invention provides a method for monitoring the resistive current value in the leakage current of a lightning arrester, in which an actual measuring instrument composed of a precision resistive element, a capacitive element and an ammeter is used. The method includes the following steps (see Figure 2):

[0026] (1) Use a current sensor to introduce the full leakage current flowing through the arrester into the actual measuring instrument;

[0027] (2) Use the selected precision resistive components and capacitive components to decompose the total leakage current flowing through the arrester into resistive current and capacitive current;

[0028] (3) Amplify resistive current and capacitive current to mA level through current amplifier;

[0029] (4) Use a high-precision data collector to determine the zero-crossing time of the resistive current and capacitive current, and measure the values of the average resistive current and capacitive current at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com