Follow-up detector for two dimension moving point steel cable tension and displacement

A detection device, wire rope technology, applied in the direction of tension measurement, the use of optical devices to transmit sensing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

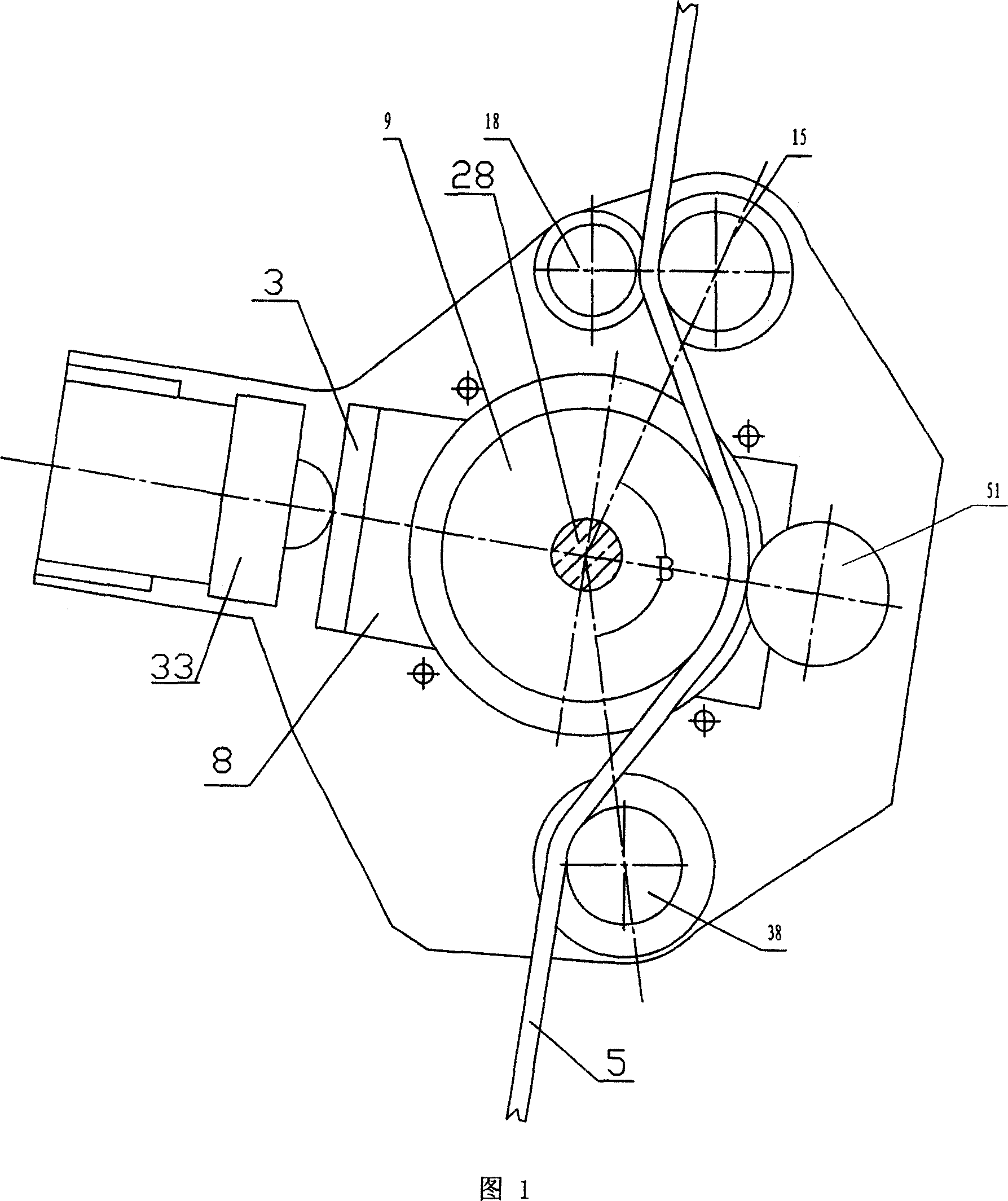

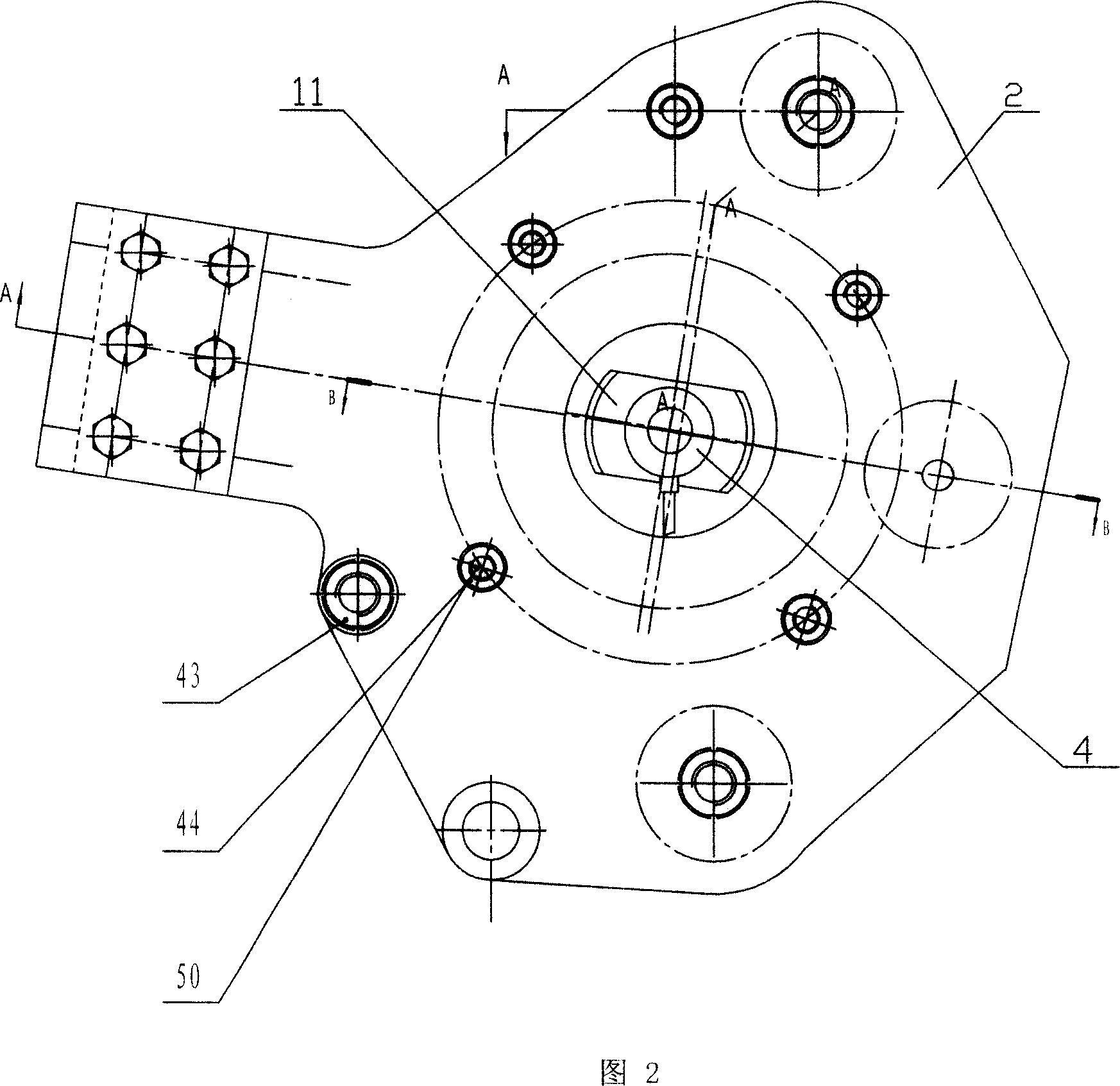

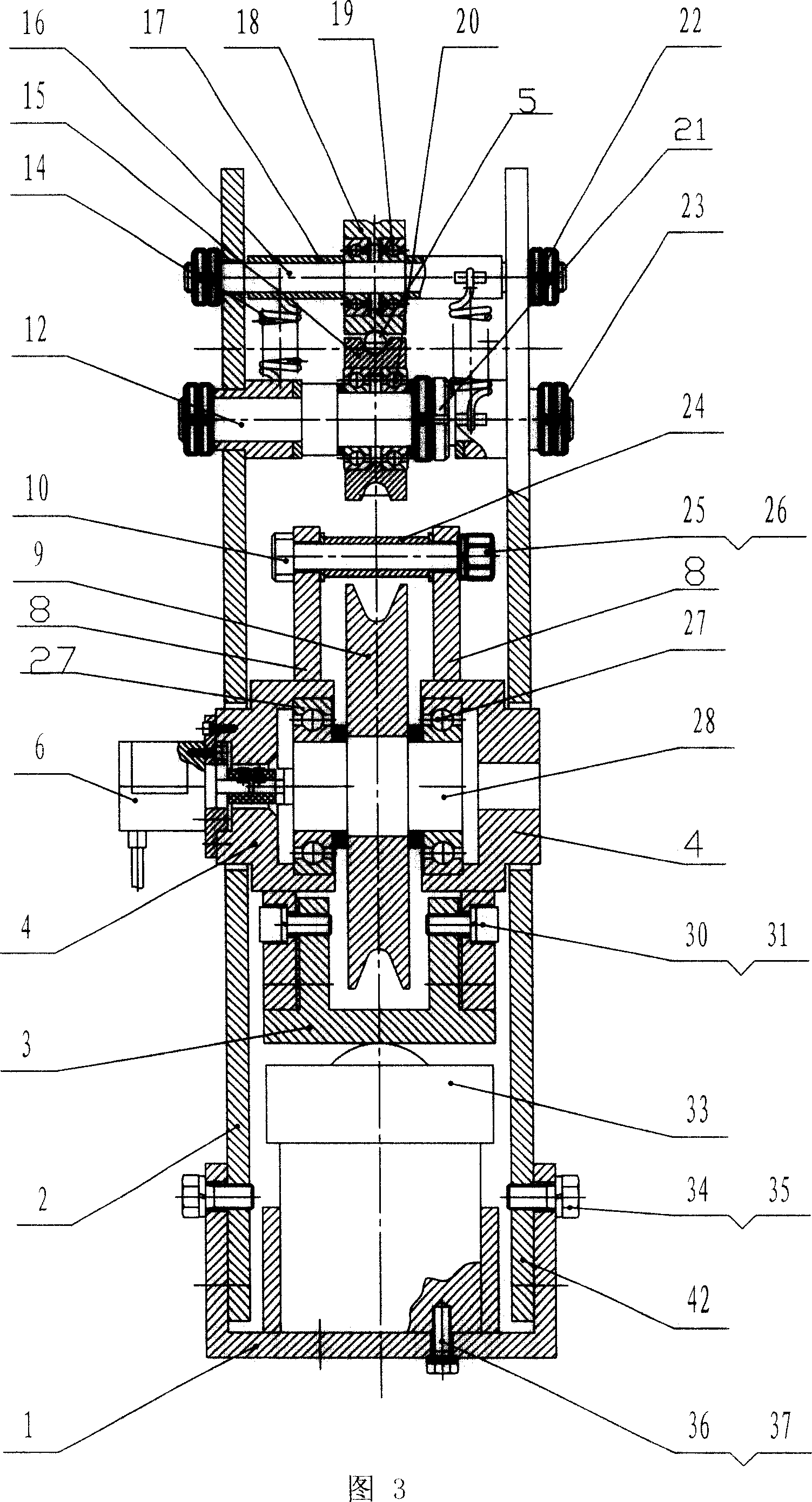

[0016] Further illustrate the embodiment of the present invention below in conjunction with accompanying drawing, as Fig. 1, the technical scheme that the present invention solves the problems of the technologies described above is: steel wire rope 5 penetrates from lower pulley 38, reaches upper pulley 15 through large pulley 9 and passes through, and large pulley 9 is fixed on the big wheel shaft 28, and the rotary encoder 6 is fixed on one end of the big wheel shaft 28. When the steel wire rope 5 moves up and down, it drives the big pulley 9 and the moving disk of the rotary encoder 6 to rotate. In theory, every time the big pulley 9 rotates , the wire rope 5 will move the large pulley 9 for a distance of circumference s, and the rotary encoder 6 will send n pulses, so the length L=k that the steel rope moves can be measured according to the number m of pulses sent by the rotary encoder 6 · m (the coefficient k=s / n in the formula). Of course, due to slipping between the wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com