Circuit board structure and making method

A circuit board and manufacturing method technology, which is applied in the direction of multilayer circuit manufacturing, including printed electrical components, and the formation of electrical connections of printed components, can solve the problems of increased process time, complicated process steps, and increased process costs, and achieve a reduction in process cost, shorten process time, and increase the effect of surface wiring density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

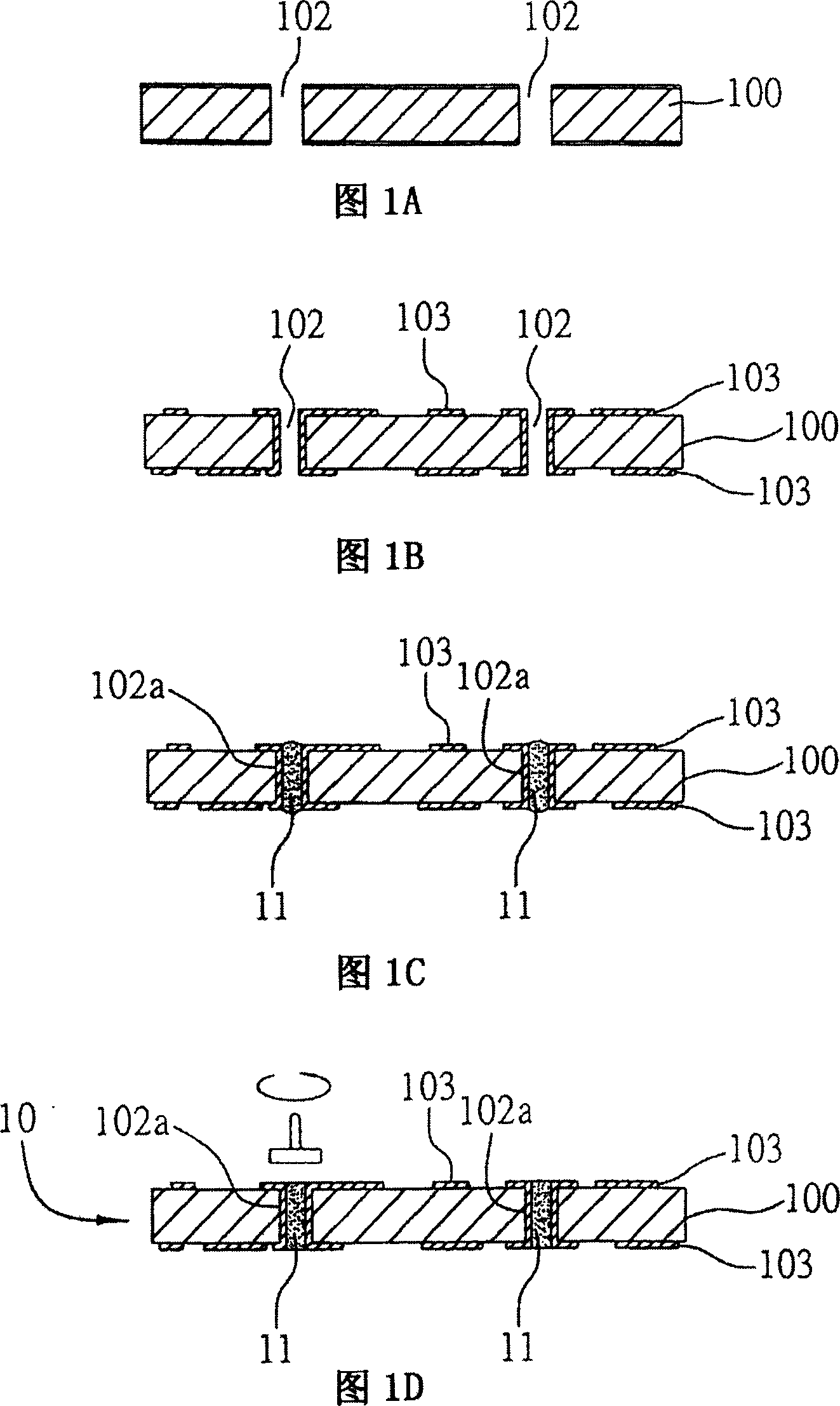

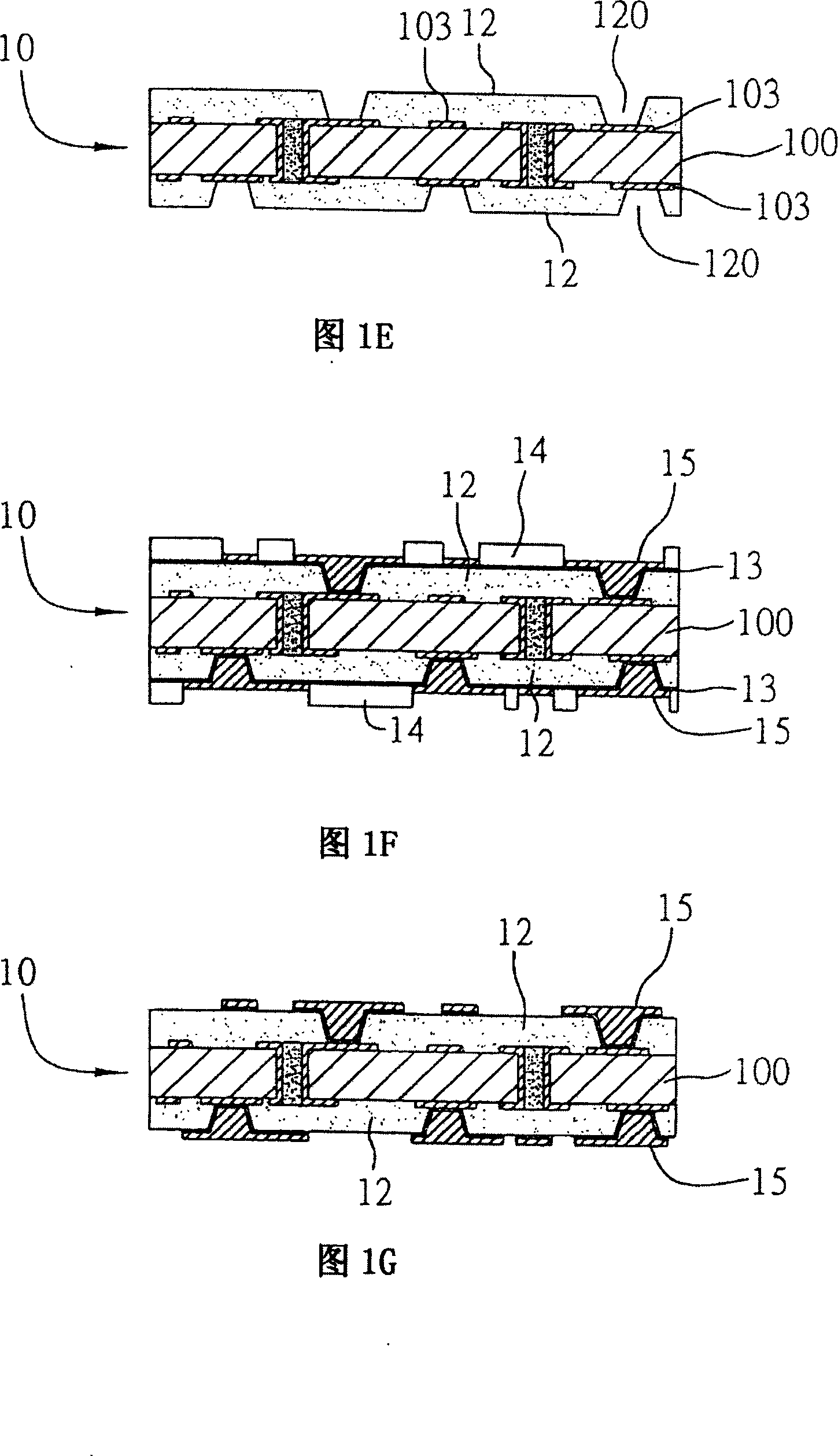

[0024] Please refer to FIGS. 2A to 2H , which are schematic cross-sectional views of the circuit board structure manufacturing method of the present invention.

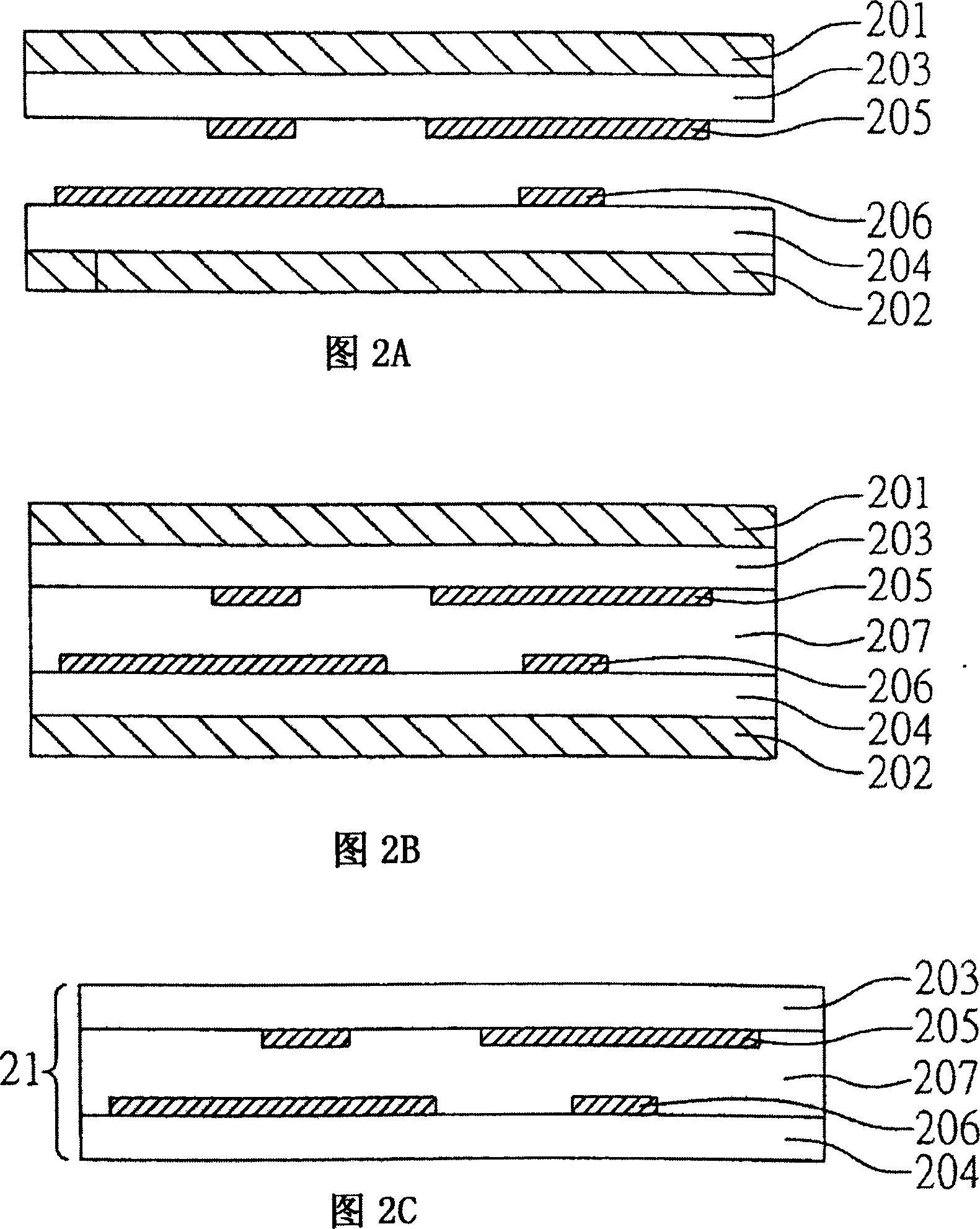

[0025] Please refer to FIG. 2A , first a first carrier board 201 and a second carrier board 202 are provided, a first dielectric layer 203 is formed on the first carrier board 201, and a first dielectric layer 203 is formed on the first dielectric layer 203. Circuit layer 205 ; forming a second dielectric layer 204 on the second carrier board 202 , and forming a second circuit layer 206 on the second dielectric layer 204 . The above-mentioned first and second dielectric layers 203, 204 can be, for example, epoxy resin (Epoxy resin), polyimide (Polyimide), cyanate ester (Cyanate ester), glass fiber (Glass fiber), bisbutene Bismaleimide triazine (BT, Bismaleimide triazine) or mixed glass fiber and epoxy resin and other materials. The first dielectric layer 203 and the second dielectric layer 204 are made of the same ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com