Magnetic head unit

A magnetic head device and magnetic function technology, applied in the configuration/installation of the recording head, supporting the head, magnetic recording, etc., can solve the problems of reducing the floating distance of the slider, reducing the magnetic function part, and reducing the floating amount of the magnetic head, so as to avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

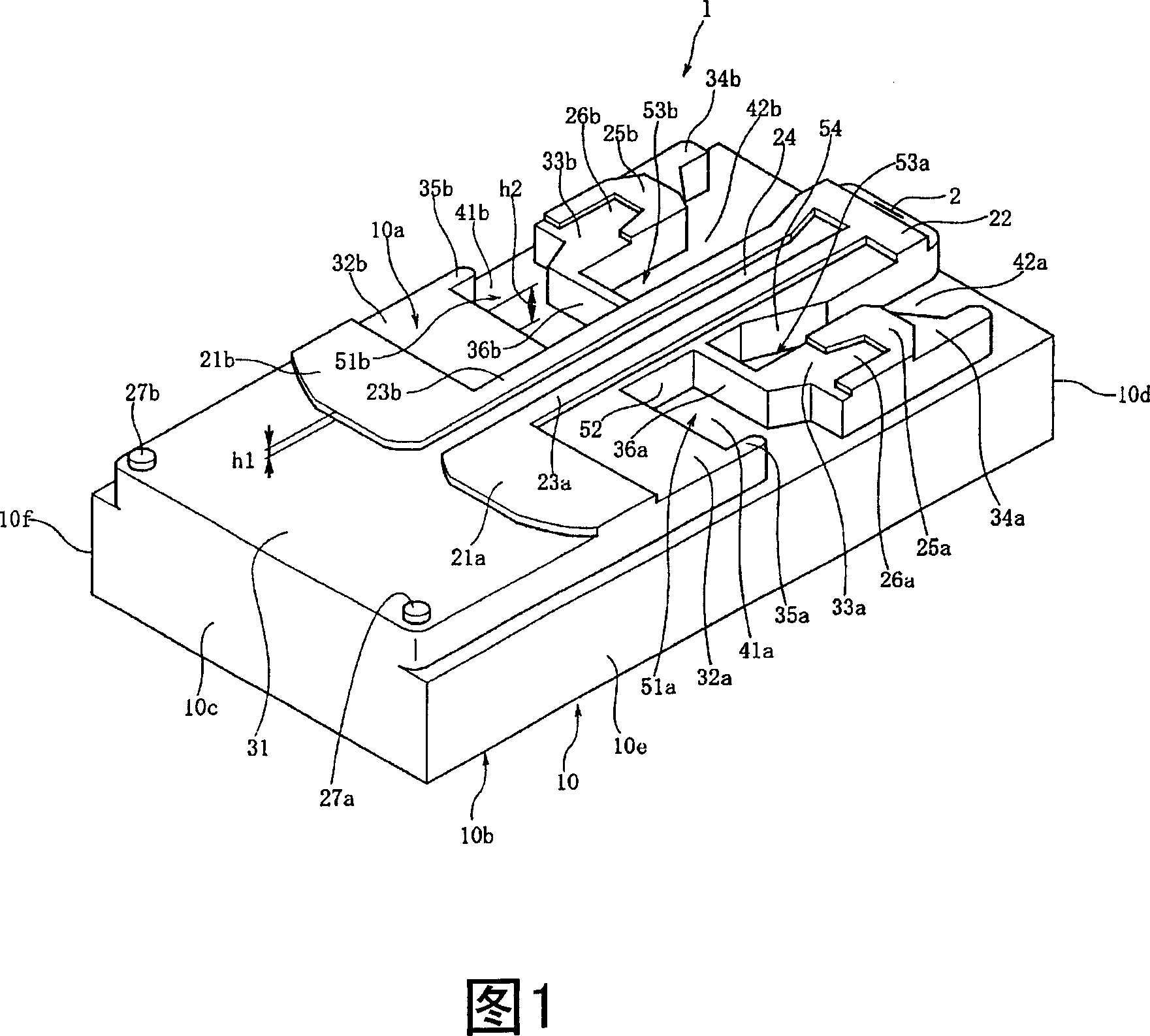

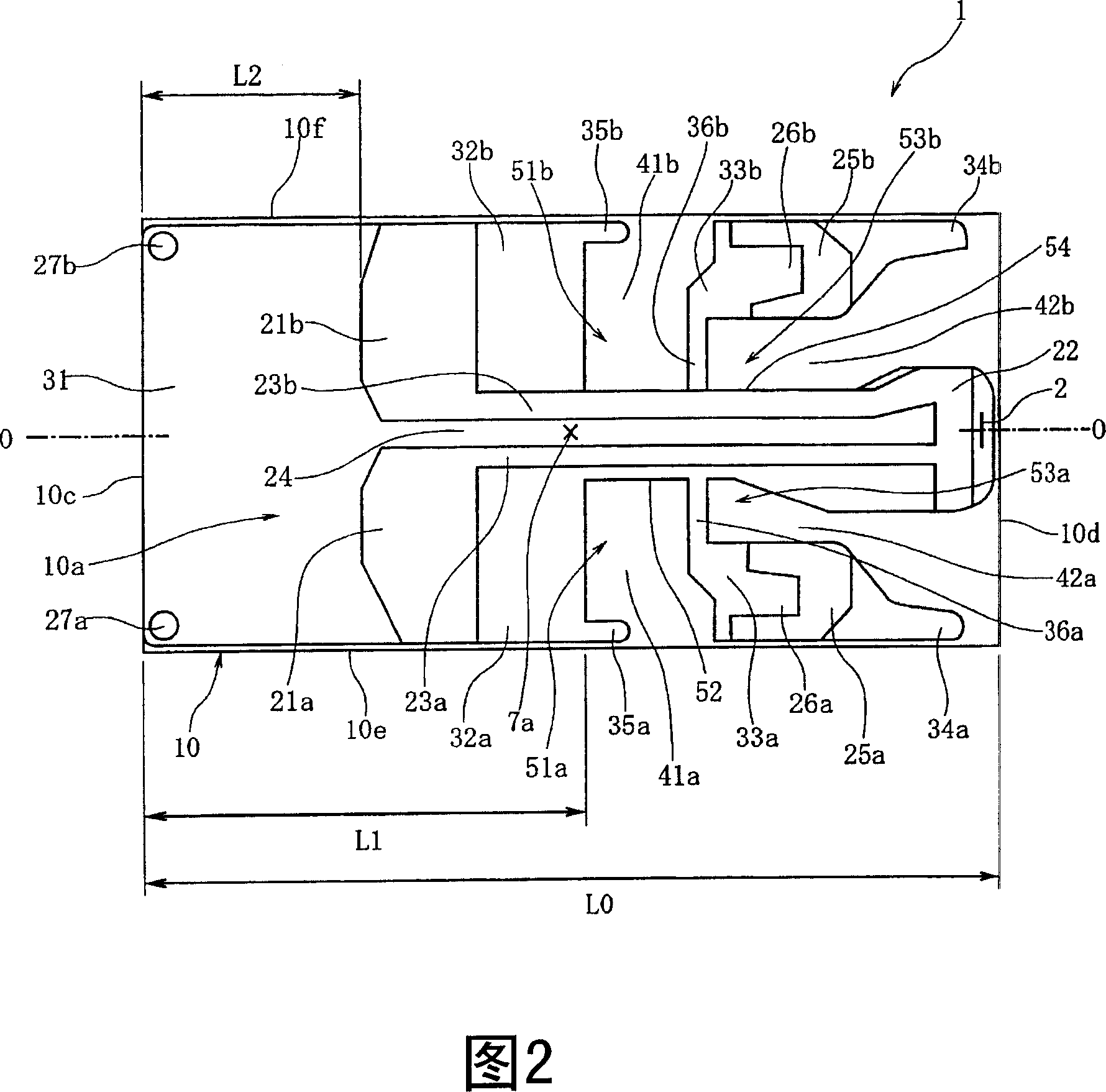

[0078] A slider having the same structure as the magnetic head device 1 of the embodiment and the magnetic head devices 1A and 1B of the modified examples was simulated by computer analysis. In this simulation, the slider 10 of the magnetic head device 1 has a long side of 124 mm, a short side of 0.70 mm, a depth h1 of 0.15 μm, and a depth h2 of 3 μm. The pressing force (load pressure) acting on the contact point 7a toward the recording medium D was 19.6 mN, and the rotational speed of the recording medium D was 3600 rpm.

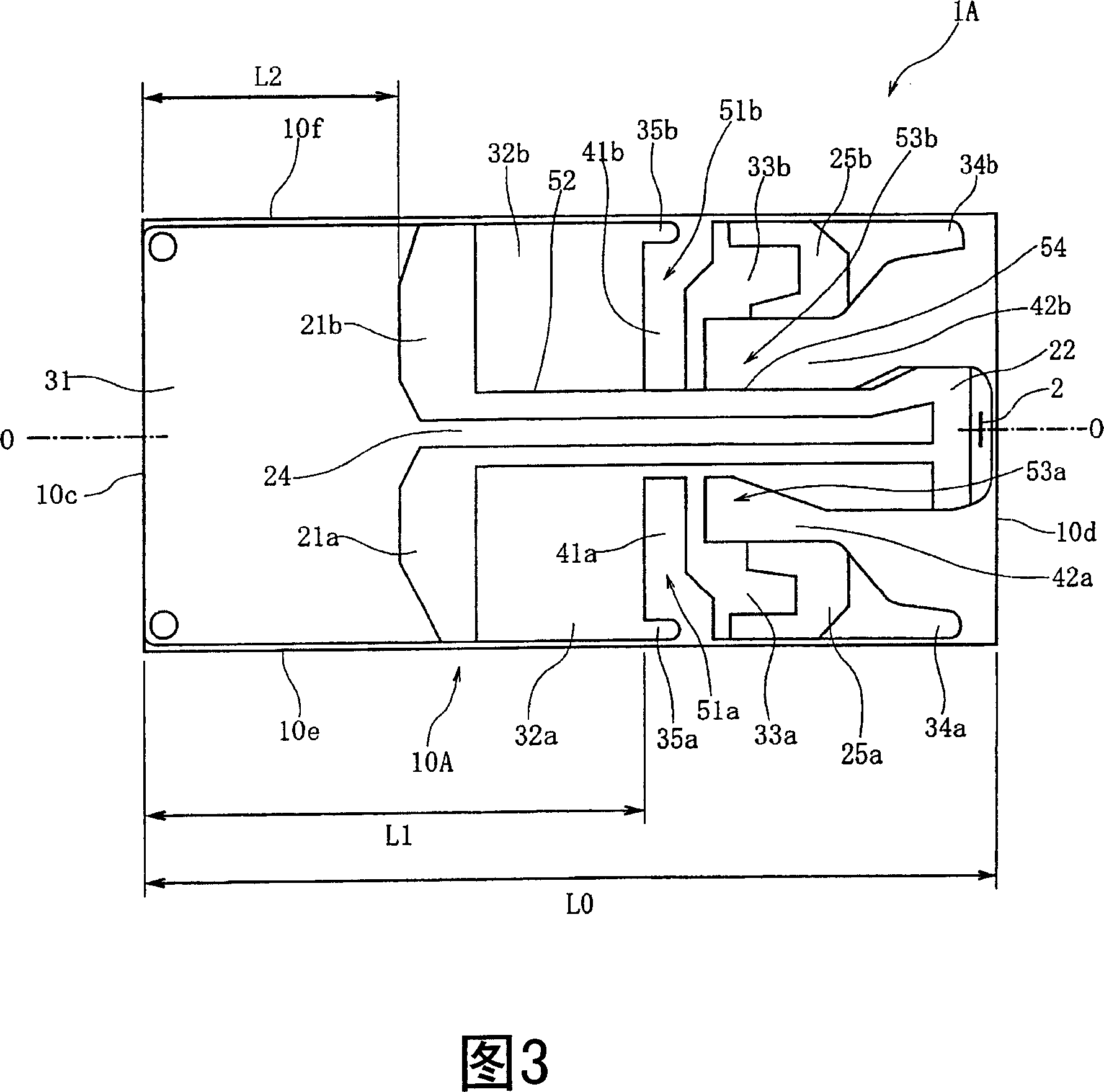

[0079] Simulations were performed for Comparative Examples and Examples in which the ratio L1 / L0 of the distance L1 from the guide-side end surface 10c to the tips of the first negative pressure generating portions 51a, 51b and the total length L0 of the slider 10 was changed. As described with reference to the relationship between the embodiment shown in FIGS. 1 and 2 and the modified examples shown in FIGS. 3 and 4, the first front positive pressure surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com