Aluminium belt cutting machine

A slitting machine, aluminum strip technology, applied in metal processing, coiling strips, sending objects, etc., can solve the problems of reducing production efficiency, uneven aluminum strip, wrinkling, etc., to achieve stable and reliable work, work efficiency High and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

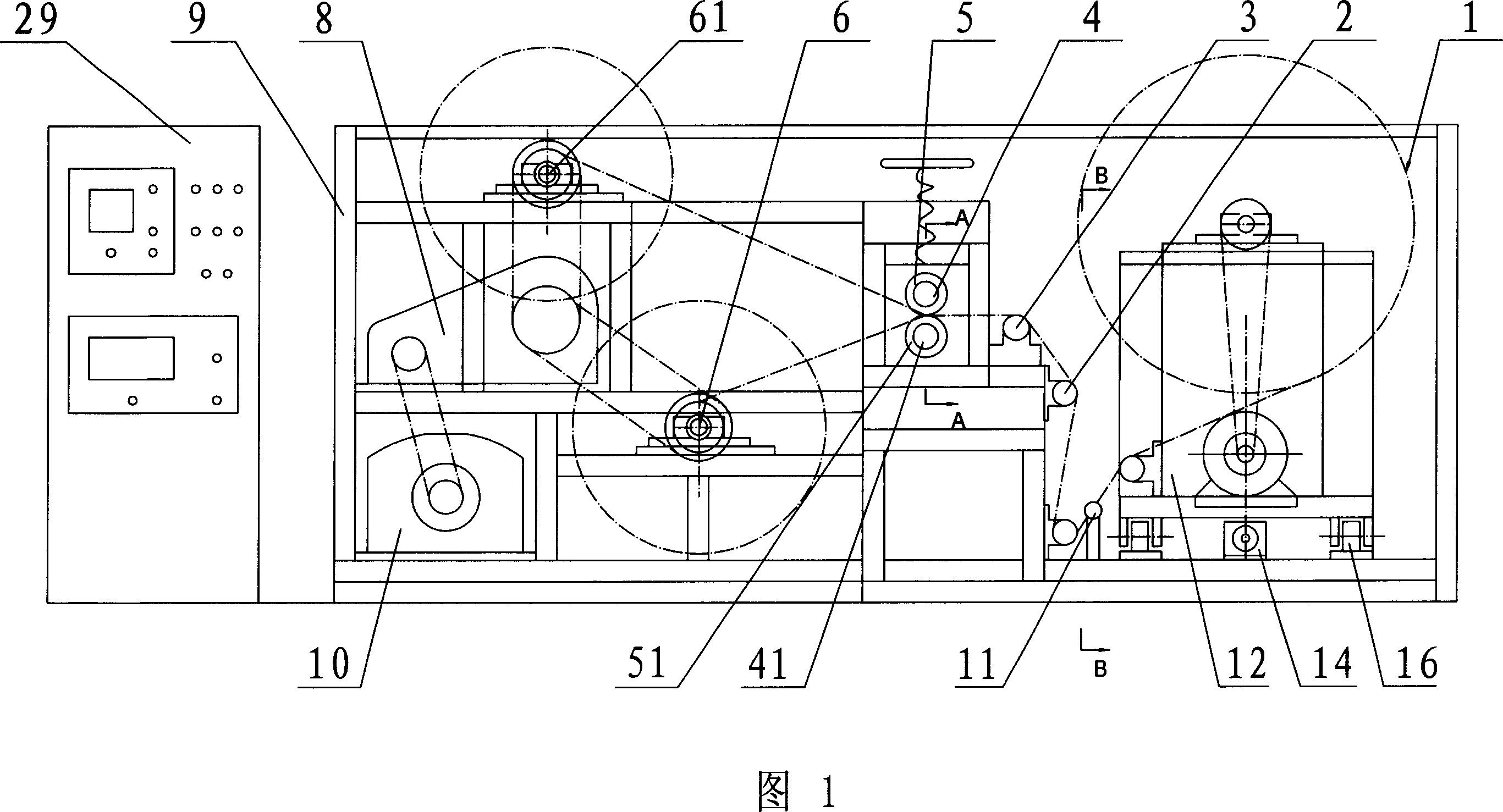

[0015] The present invention will be further described below in conjunction with the above-mentioned drawings and specific embodiments.

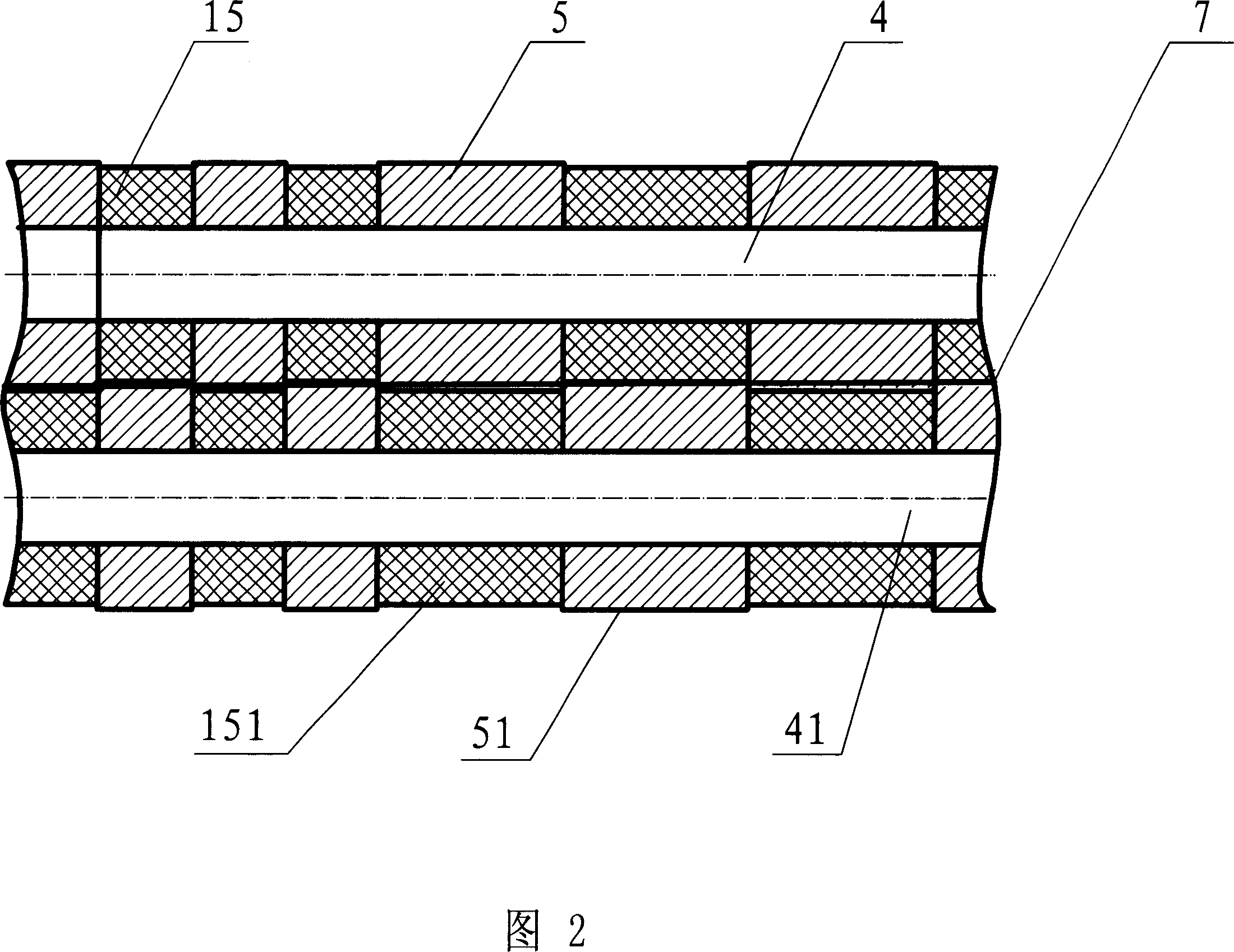

[0016] As shown in Fig. 1 and Fig. 2, the aluminum strip slitting machine according to the present invention includes: a frame 9, and a power transmission device is arranged in the frame 9—mainly including a main motor 10 and a reduction box 8 in this embodiment , the reduction box 8 drives the relevant parts to run again, and two receiving shafts 6 and 61, two cutting blade shafts 4 and 41, some guide shafts 3 and the discharge rack 12, and the controller are also arranged in the frame 9 29. The distance between the two rewinding shafts 6 and 61 can be set according to the size of the frame 9 and the size of the material roll after rewinding, and the number of guide shafts 3 can also be set according to the size of the frame 9 Size and actual working conditions are set; On the cutting blade shafts 4 and 41, disc-shaped cutting blades 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com