Liquid crystal panel, liquid crystal television, and liquid crystal display device

A liquid crystal panel and liquid crystal technology, applied in the directions of optics, instruments, nonlinear optics, etc., can solve the problems that the display characteristics of liquid crystal display devices cannot meet the needs of large fixed TVs, reduce the oblique contrast ratio, etc., to reduce oblique light leakage and improve oblique Towards contrast, reducing the effect of oblique shading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0398]

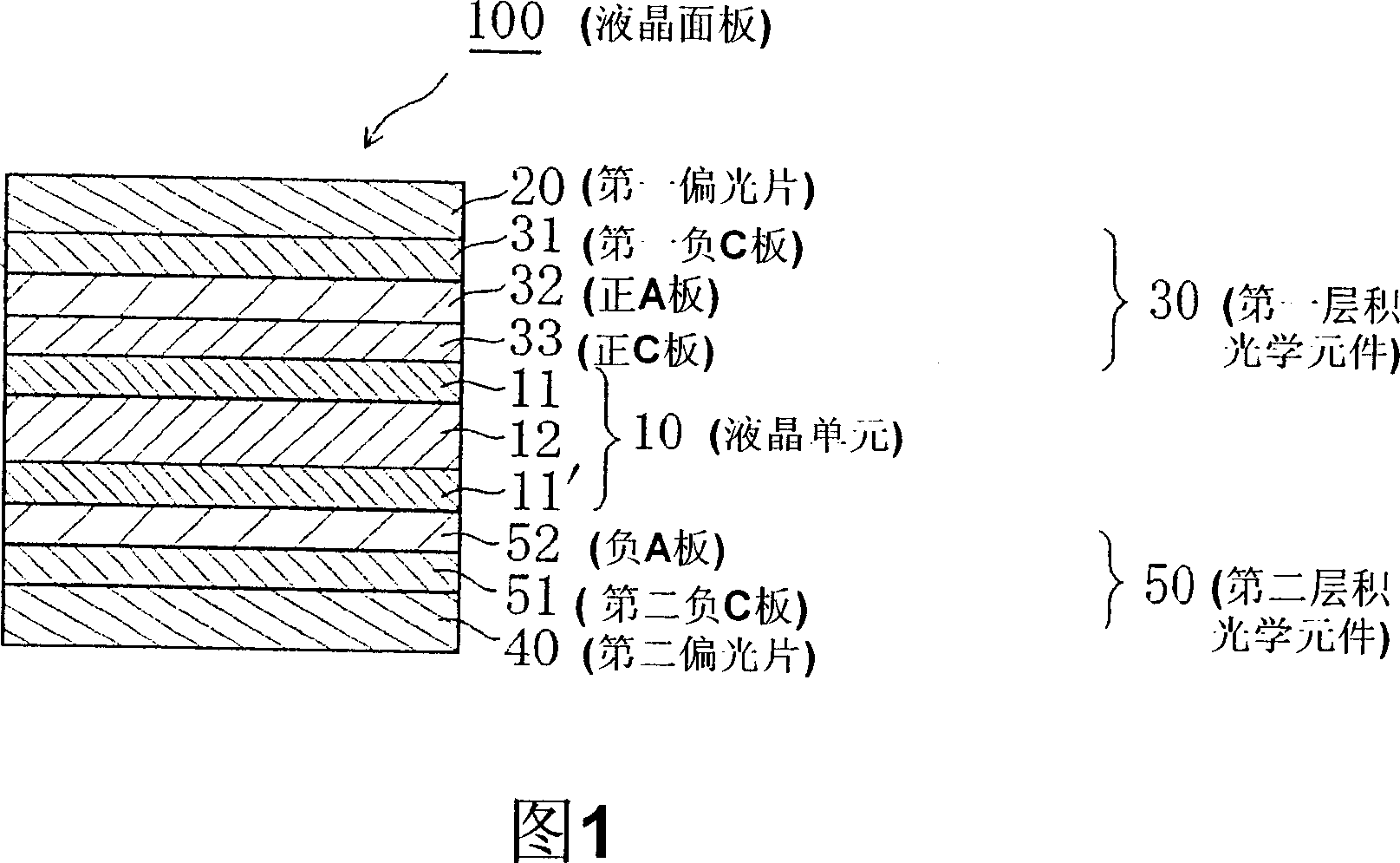

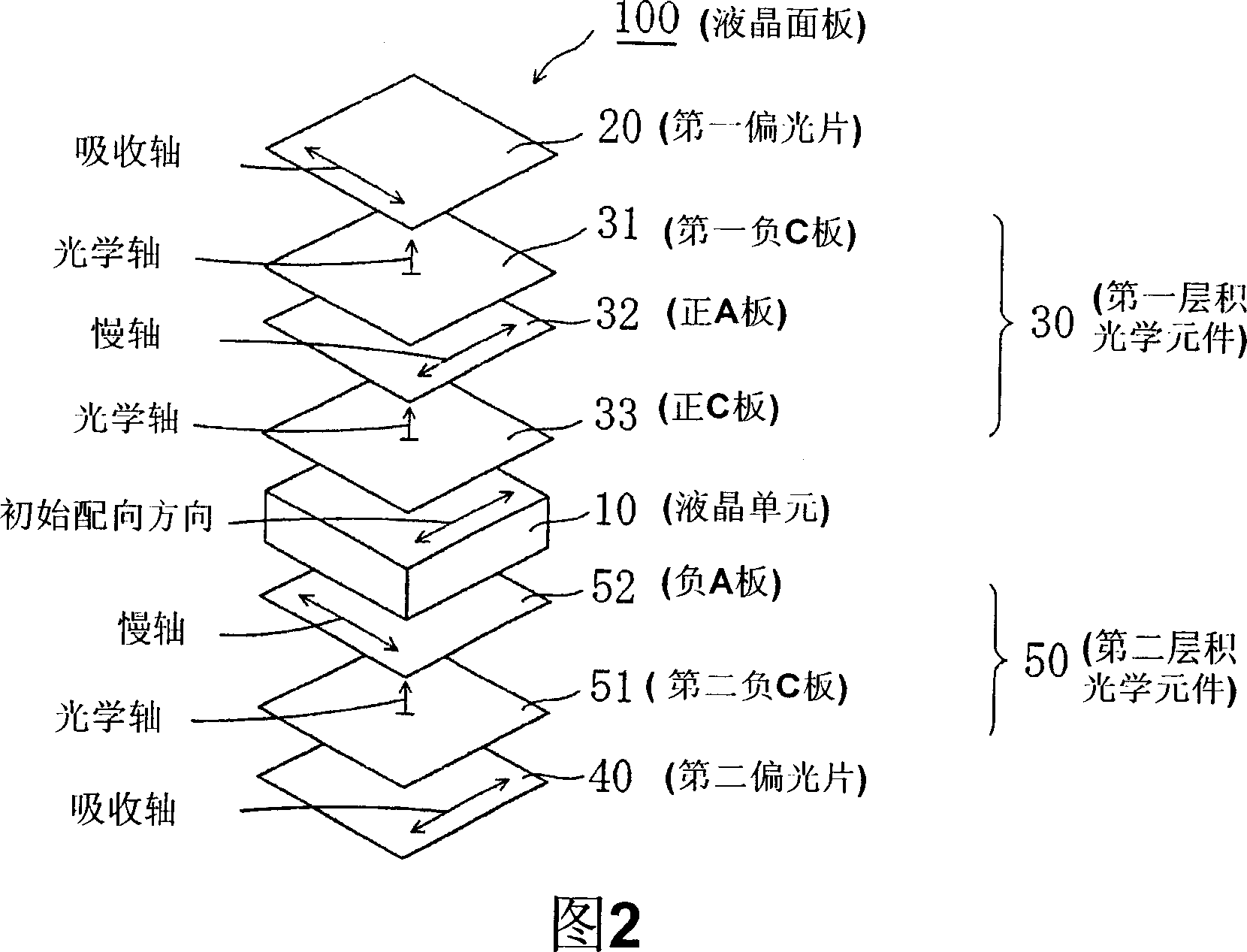

[0399] The retardation film C-2 obtained in Reference Example 8 (i.e., positive C plate) was adhered to Reference Example 12 through an adhesive layer formed of an acrylic pressure-sensitive adhesive having a thickness of 20 μm. The resulting viewing-side surface of the liquid crystal cell provided with a uniformly aligned liquid crystal layer was such that its slow axis was substantially parallel to the long side of the liquid crystal cell (ie, 0° ± 0.5°). Next, the retardation film B-2 (ie, positive A plate) obtained in Reference Example 5 was adhered to the retardation film through an adhesive layer formed of an acrylic pressure-sensitive adhesive with a thickness of 20 μm. The surface of film C-2 was such that its slow axis was substantially perpendicular to the long side of the liquid crystal cell (ie, 90° ± 0.5°). Then, the phase difference film A-2 (ie, the first negative C plate) obtained in Reference Example 2 was adhered to the The surface of the retardat...

Embodiment 2

[0403] The liquid crystal panel (ii) and the liquid crystal display device (ii) are manufactured by the same method as in Example 1, except that retardation film C-3 is used as the positive C plate, retardation film B-1 is used as the positive A plate, and phase difference film B-1 is used as the positive A plate. The difference film A-3 was used as the first negative C plate, and the retardation film A-3 was used as the second negative C plate. Table 5 shows the characteristics of the liquid crystal display device (ii).

Embodiment 3

[0405] The liquid crystal panel (iii) and the liquid crystal display device (iii) were manufactured by the same method as in Example 1, except that retardation film C-1 was used as the positive C plate, retardation film B-3 was used as the positive A plate, and phase difference film B-3 was used as the positive A plate. The difference film A-1 was used as the first negative C plate, and the retardation film A-1 was used as the second negative C plate. Table 5 shows the characteristics of the liquid crystal display device (iii).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com