Drum washing dryer and its control method

The technology of a drum washing machine and its control method is applied in the direction of washing machine control devices, household clothes dryers, washing machines with containers, etc., which can solve the problems of wrinkling of laundry, increased dehydration travel time, increased power consumption, etc., to prevent Effects of wrinkling, improvement of dehydration performance, and shortening of dehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

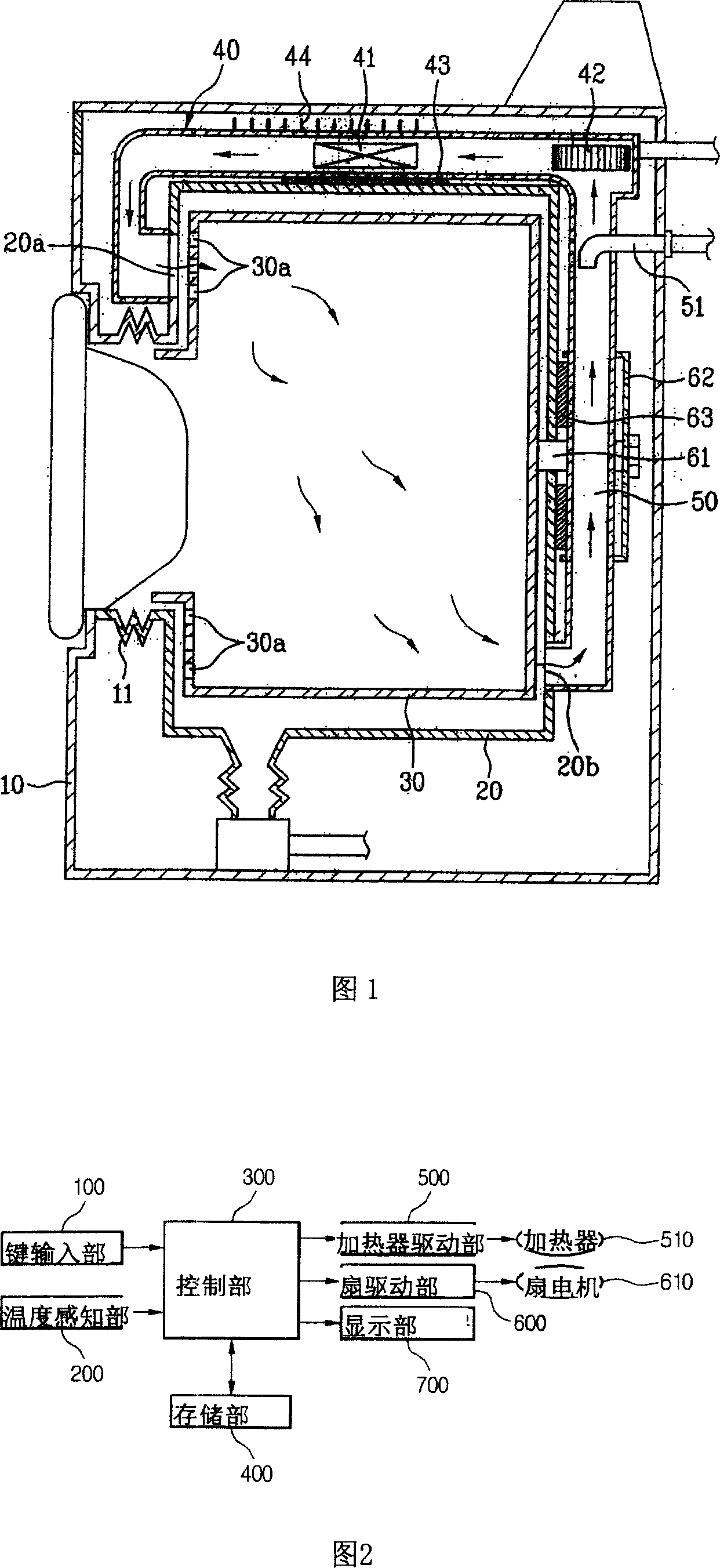

Image

Examples

Embodiment 1

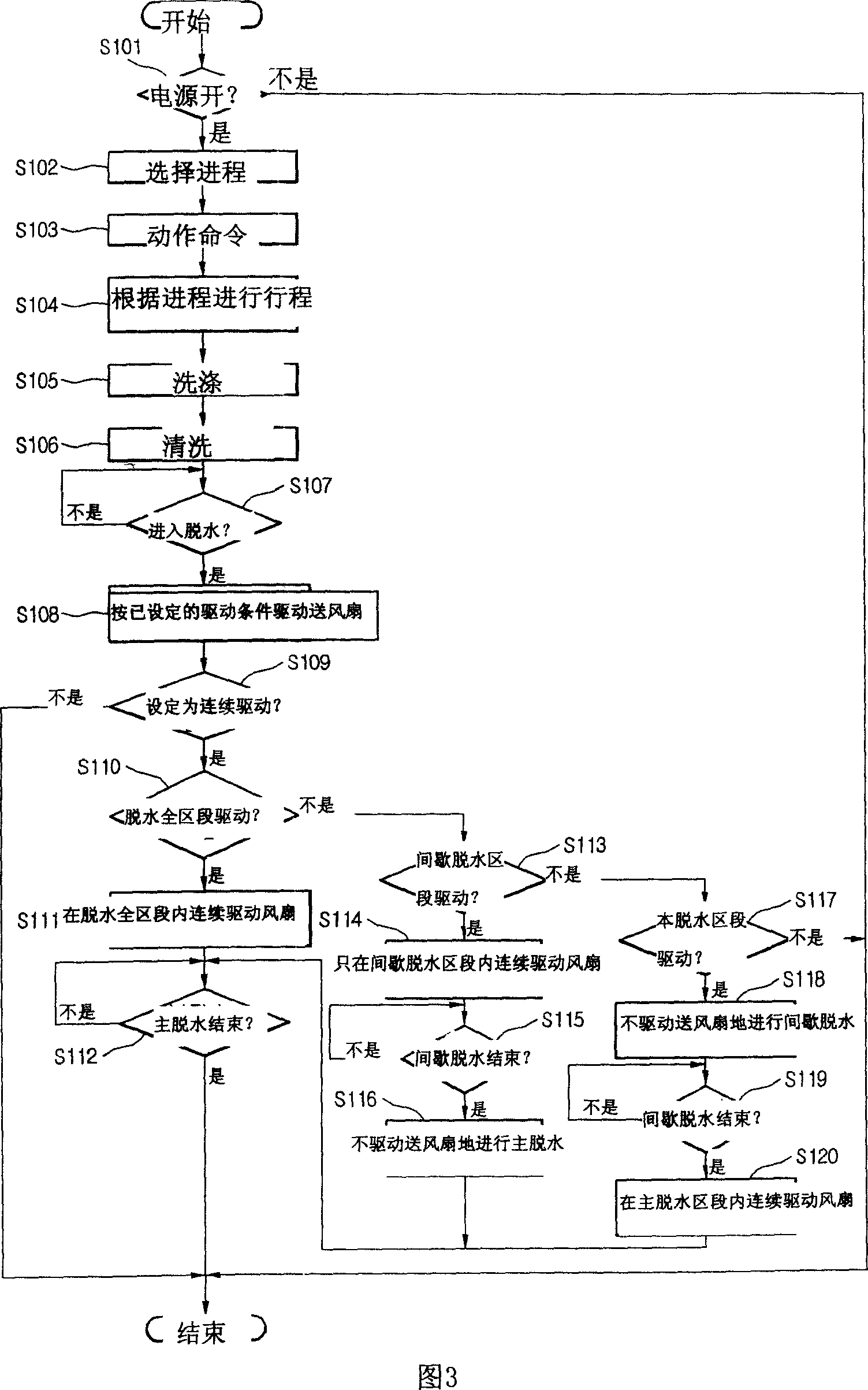

[0071] In the first embodiment of the control method of the dual-purpose washing machine of the present invention, in the dehydration process, the blower fan is selectively driven according to the set sections.

[0072] Next, with reference to FIG. 3, the first embodiment of the method for controlling the combined drying and washing machine of the present invention will be described. After turning on the power, the user selects the required processes S101-S102.

[0073] After the user selects a washing process and inputs an action command, the washing machine performs corresponding washing and cleaning processes S103 - S106 sequentially according to the selected washing process.

[0074] After the cleaning process is finished, it is judged S107 whether it is at the entry point of the dehydration process.

[0075] Judgment result S107, if it is at the entry point of the dehydration process, drive the blower fan according to the set driving conditions S108.

[0076] Next, it i...

Embodiment 2

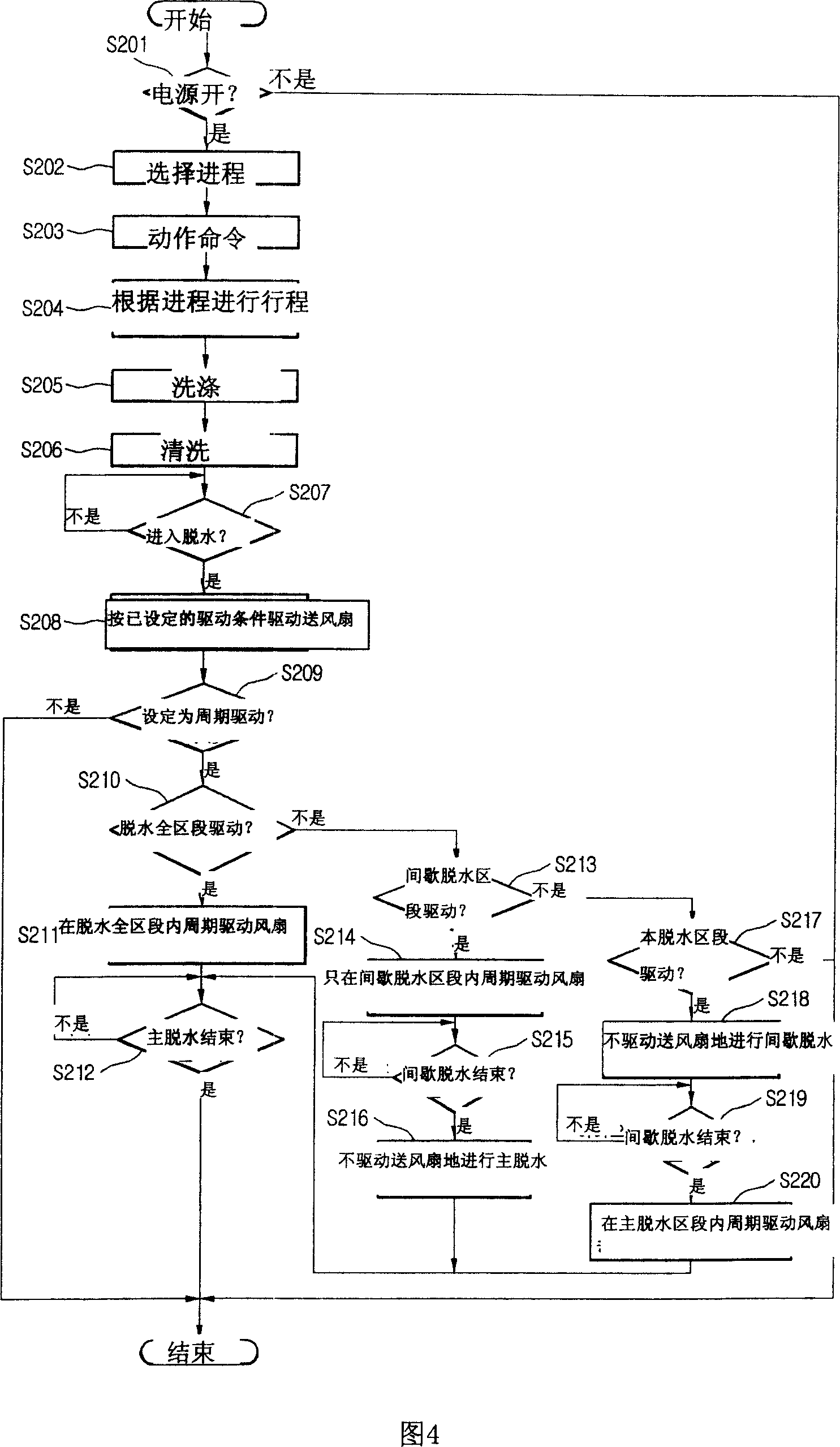

[0084] Next, referring to FIG. 4, the second embodiment of the method for controlling the combined drying and washing machine of the present invention will be described. After turning on the power, the user selects the required processes S201-S202.

[0085] After the user selects a washing course or inputs an action command, the washing machine sequentially performs corresponding washing and cleaning procedures S203-S206 according to the selected washing course.

[0086] After the cleaning process is finished, it is judged S207 whether it is at the entry point of the dehydration process.

[0087] Judgment result S207, if it is at the entry point of the dehydration process, drive the blower fan according to the set driving conditions S208.

[0088] Next, it is judged S209 whether the driving condition of the blower fan is periodic driving.

[0089] Judgment result S209, if it is periodic driving, then judge whether to drive in the entire dehydration section or not S210.

[0...

Embodiment 3

[0103] In the third embodiment of the control method of the dual-purpose washing machine of the present invention, the blower fan is continuously driven in the dehydration stroke according to the set section; the heater is driven according to the set temperature condition.

[0104] Fig. 5 is a flow chart of the third embodiment of the control method of the dual-purpose drum washing machine of the present invention.

[0105] Next, with reference to FIG. 5, a third embodiment of the method for controlling the combined drying and washing machine of the present invention will be described. After turning on the power, the user selects the required processes S101-S102.

[0106] After the user selects a washing course and inputs an action command, the washing machine sequentially performs corresponding washing and cleaning procedures S103-S106 according to the selected washing course.

[0107] After the cleaning process is finished, it is judged S107 whether it is at the entry point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com