Crane cabin

A driver's cab and crane technology, applied in the field of driver's cab, can solve problems such as unfavorable driver's health and heat energy loss, and achieve the effects of avoiding human injury, happy and convenient work, and broadening the field of vision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

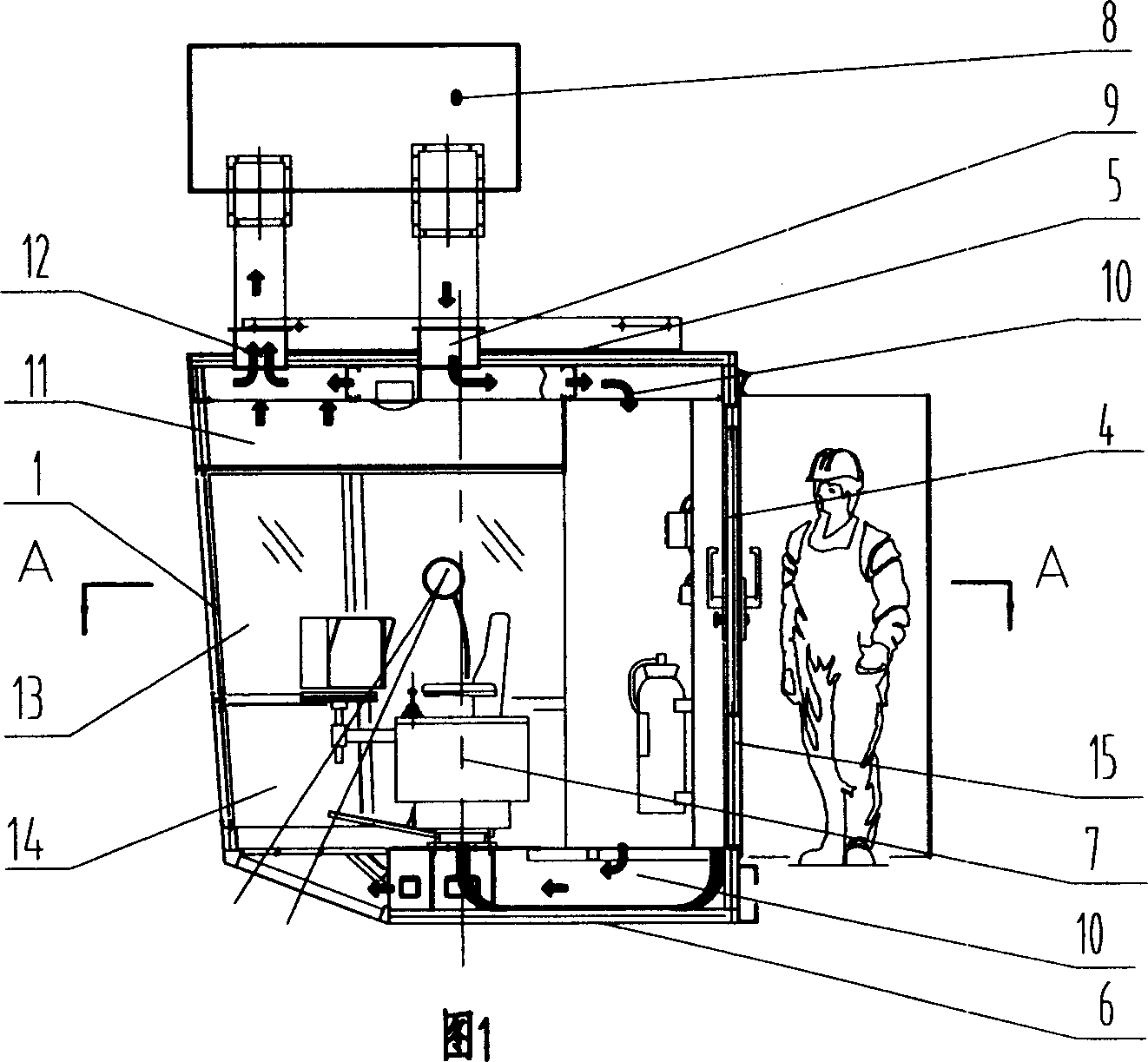

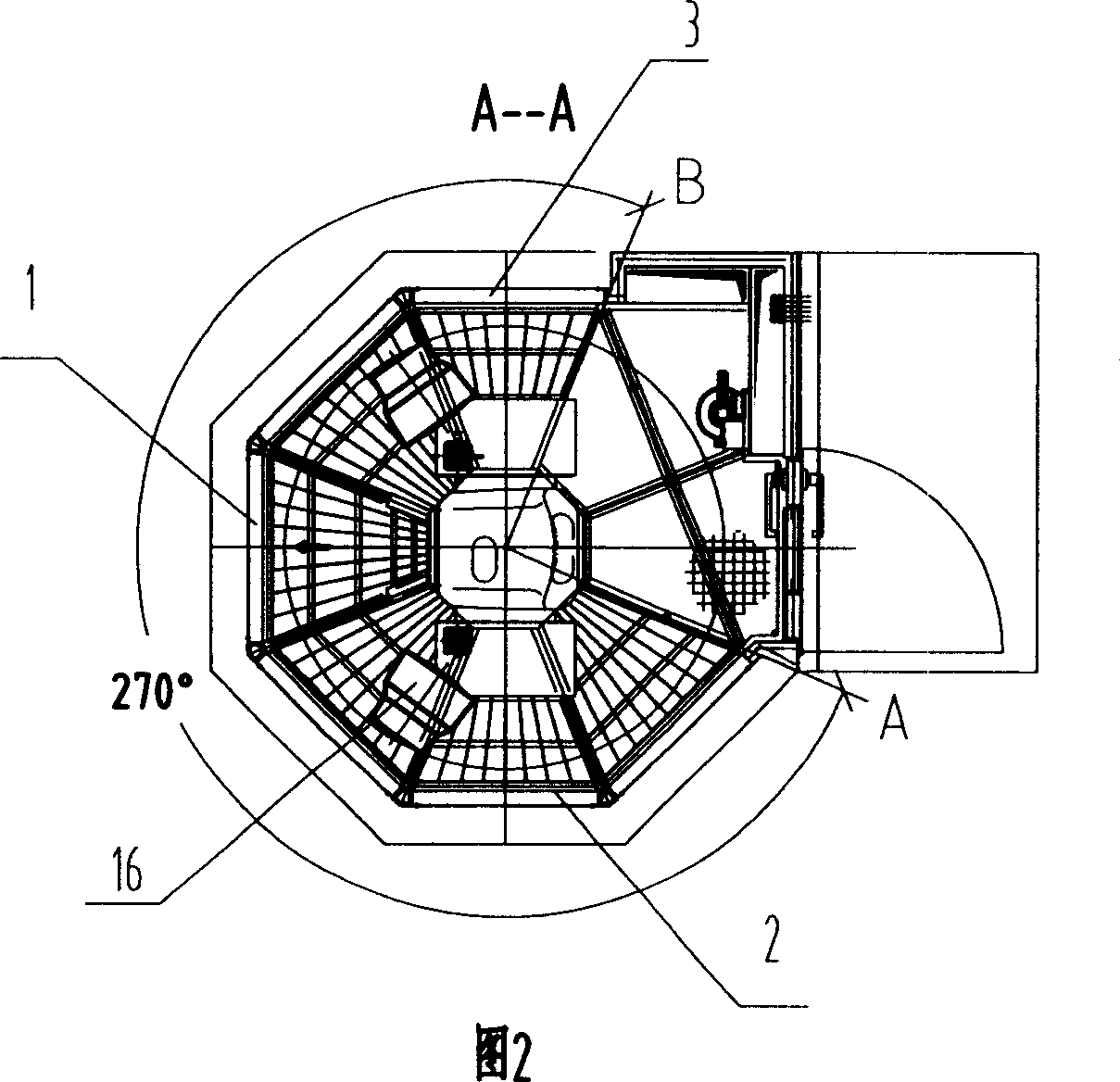

[0022] As shown in Figures 1 and 2, a crane cab is composed of a front side panel 1, a left side panel 2, a right side panel 3, a rear side panel 4, a top cover 5, and a bottom panel 6. The front window and the lower window are provided with side windows on the left and right side panels, doors are provided on the rear side panels, and a driver's seat 7 and an operating console are provided on the bottom panel in the driver's compartment. The crane driver's cab is provided with an integral air conditioner 8 above the top cover 5, and the air-conditioning cold air outlet 9 goes down to the bottom plate along the vertical wall along the top floor through the cold air duct 10, then to the seat 7 of the driver's cab, and then from the seat. The space is gradually filled from bottom to top to avoid harm to the human body. The hot air is sent from the hot air channel 11 to the air conditioner outlet 12, and the hot air is imported into the hot air channel from the ceiling in a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com