Sealing structure of discharge lamp

A sealing structure and technology for discharge lamps, which are applied in the fields of discharge lamps, discharge tube/lamp manufacturing, gas discharge lamp parts, etc., can solve problems such as reduced work efficiency and difficulty in welding and winding foils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The best mode for carrying out the present invention will be described below with reference to FIGS. 1 to 10 .

[0030] 【Example】

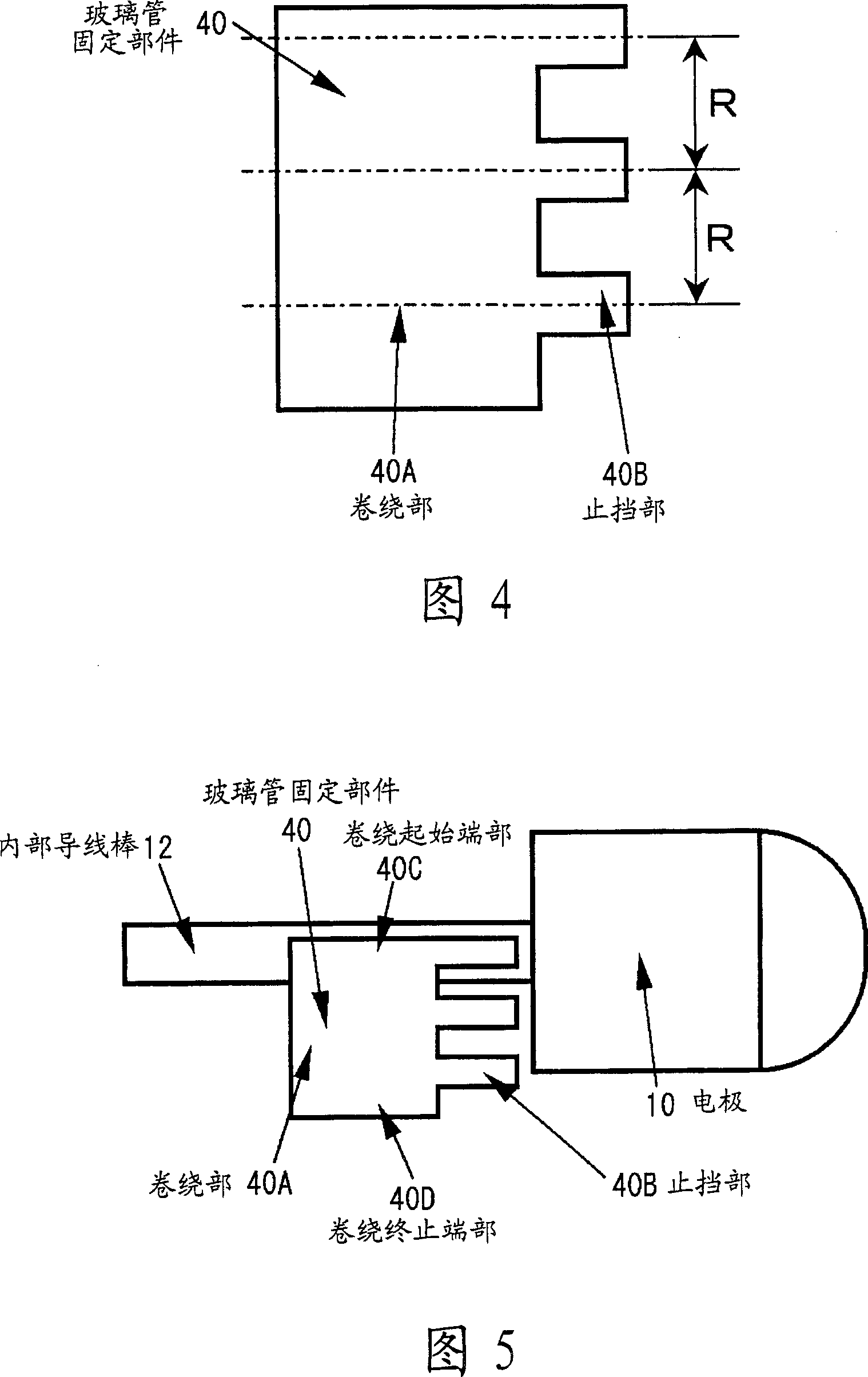

[0031] In the sealing part of the discharge lamp according to the embodiment of the present invention, the winding part of the glass tube fixing member is wound around the circumferential surface of the lead rod of the electrode, and the lead rod is inserted into the cylindrical glass tube and protrudes from the end surface of the glass tube. The extended portion of the coiling portion is bent to become a stopper that restrains the glass tube from moving along the tube axis.

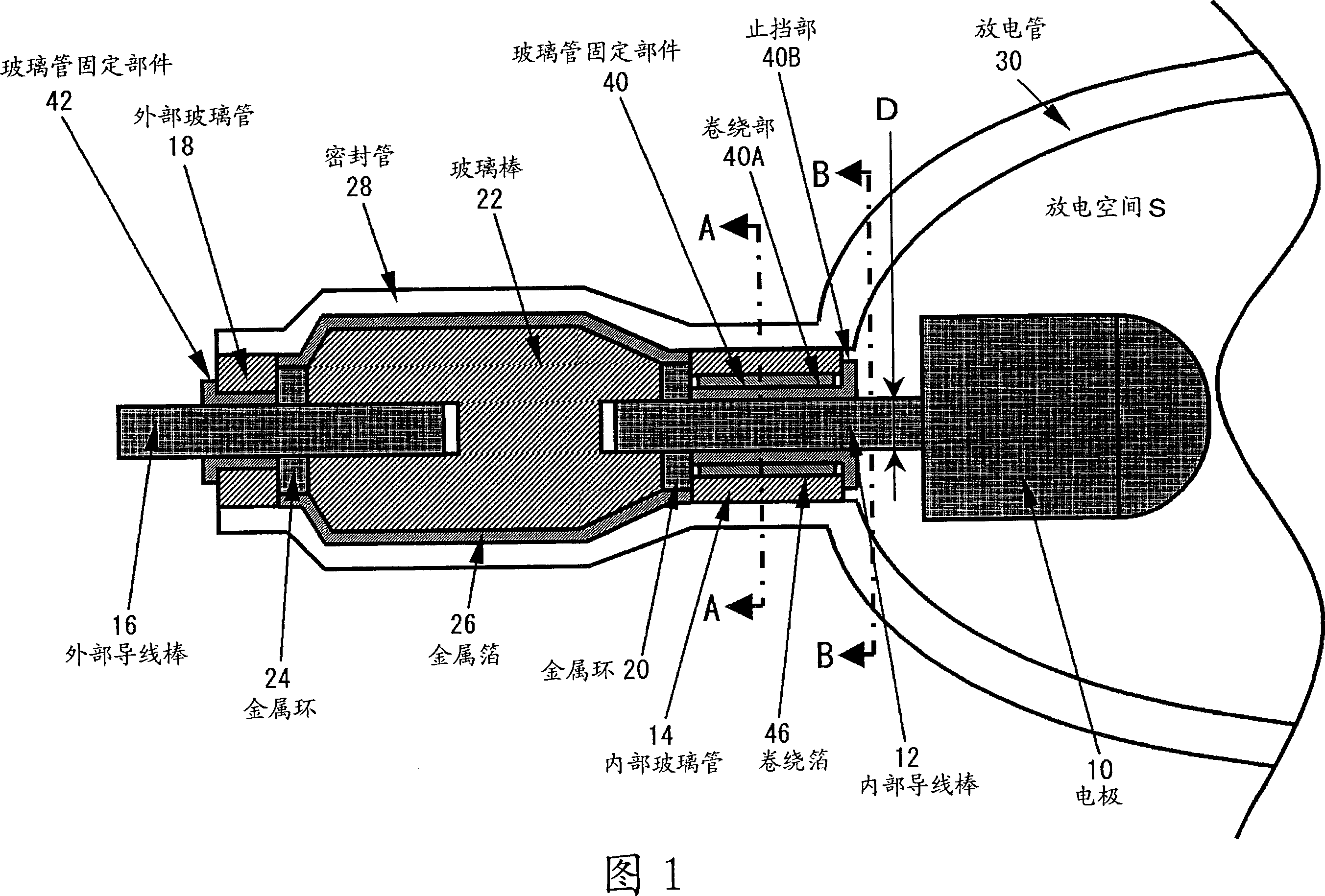

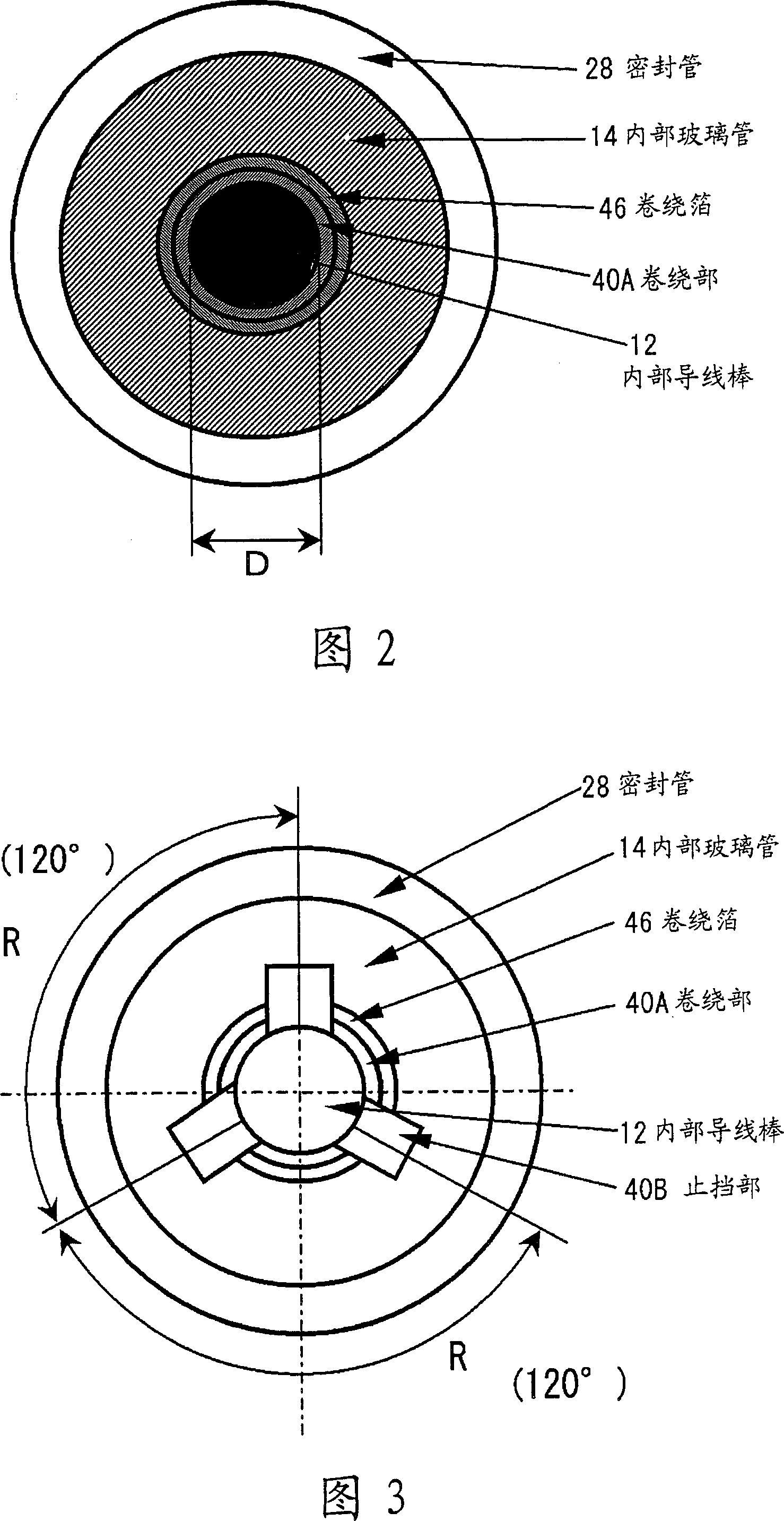

[0032]Fig. 1 is a sectional view along the axis of a sealing portion of a discharge lamp in an embodiment of the present invention. As an example, a sealing portion of a short-arc discharge lamp is shown. Fig. 2 is a sectional view along A-A of Fig. 1 . Fig. 3 is a B-B sectional view of Fig. 1 . In FIG. 1 , FIG. 2 and FIG. 3 , the discharge space S is filled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com