Fast tongue groove assembling sectional furniture

A technology of combining furniture and tongue and groove, applied in the field of furniture, can solve the problems of inconvenient disassembly, poor permanent firmness, and high cost, and achieve the effect of convenient disassembly and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

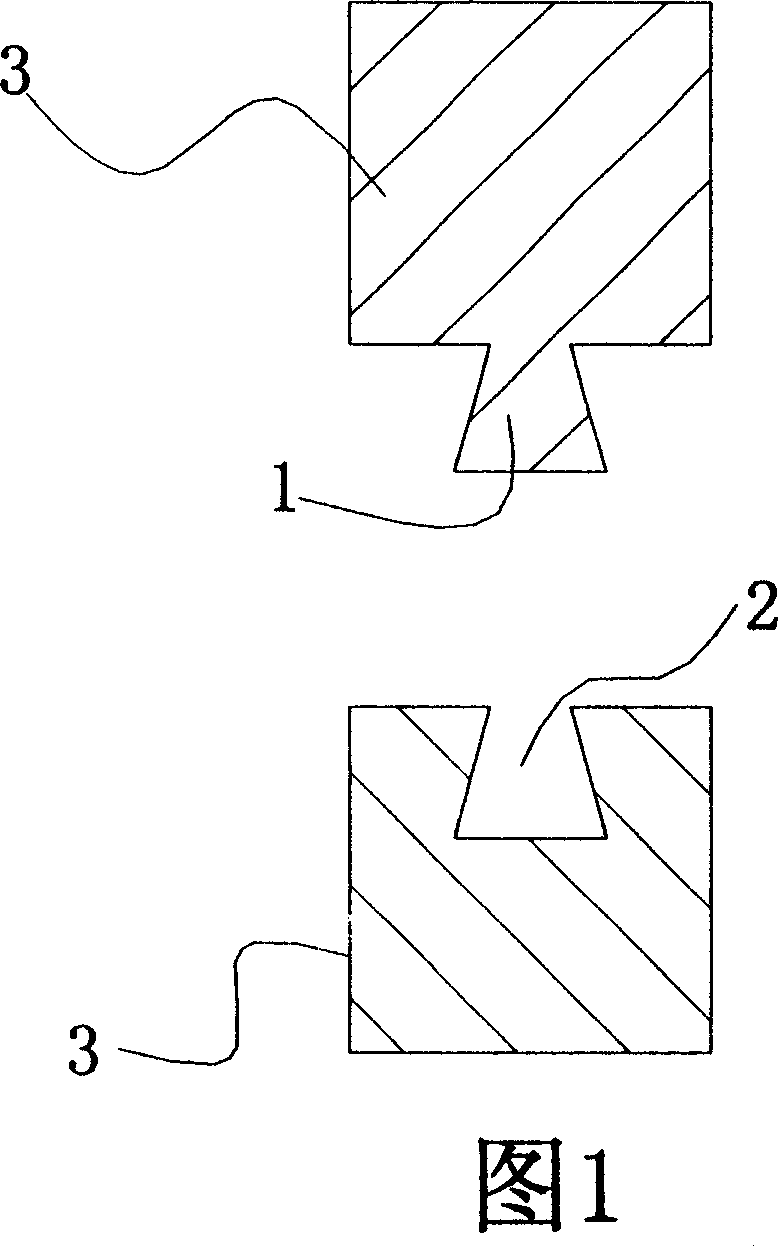

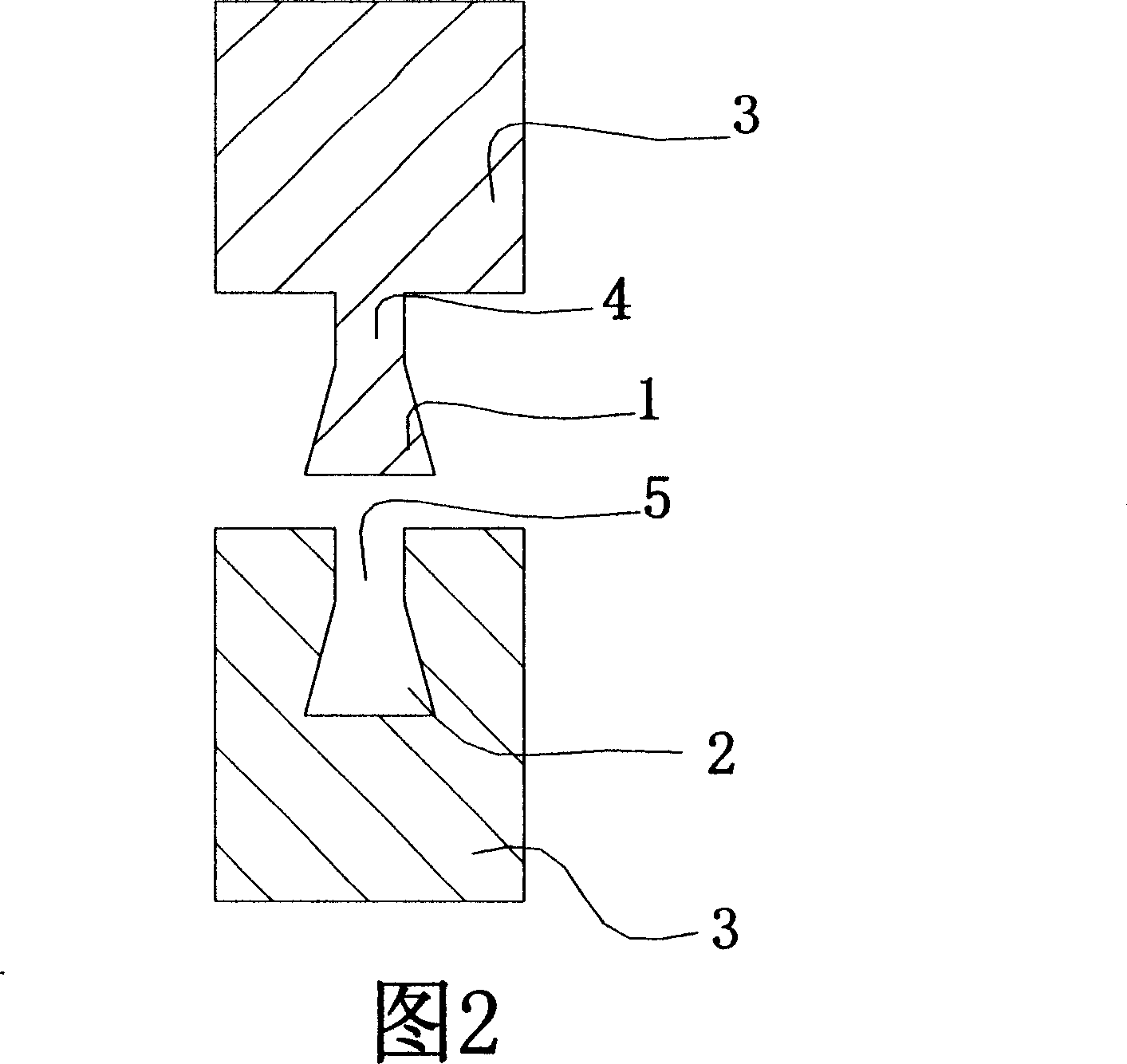

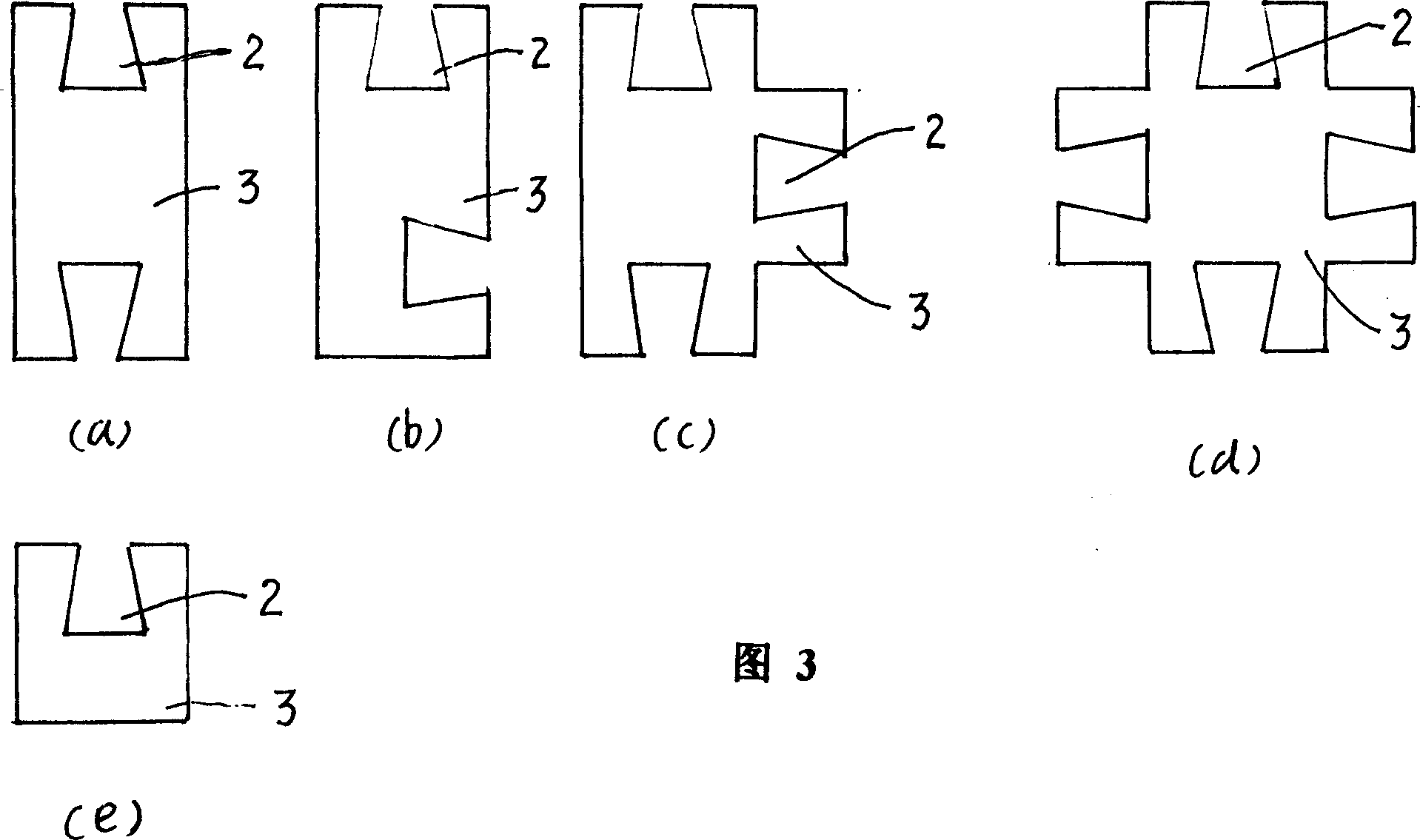

[0016] The fast tongue-and-groove assembly furniture assembly of the present invention includes components in various existing furniture. The components can be made of wood, plastic, aluminum alloy, metal and other materials suitable for furniture. The shape and structure of this kind of furniture are different, and its component parts are also different, but these parts are all the prior art, so the present invention will not be described in detail, and the purpose of the present invention is not in each component part of the furniture, but in each component The connection relationship between. In the present invention, the various parts of the furniture are connected by the tenon 1 and the groove 2, as shown in Figure 1, that is, the tenon 1 is directly inserted from the side of the groove 2, because the cross section of the tenon 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com