Method for processing salted black-fungus

A processing method and technology of black fungus, applied in application, food preparation, food science and other directions, can solve the problems of dissolution of solids, softening of fungus, no mention of product shelf life, etc., to reduce dissolution, improve quality and shelf life, maintain The effect of crispness and mouthfeel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

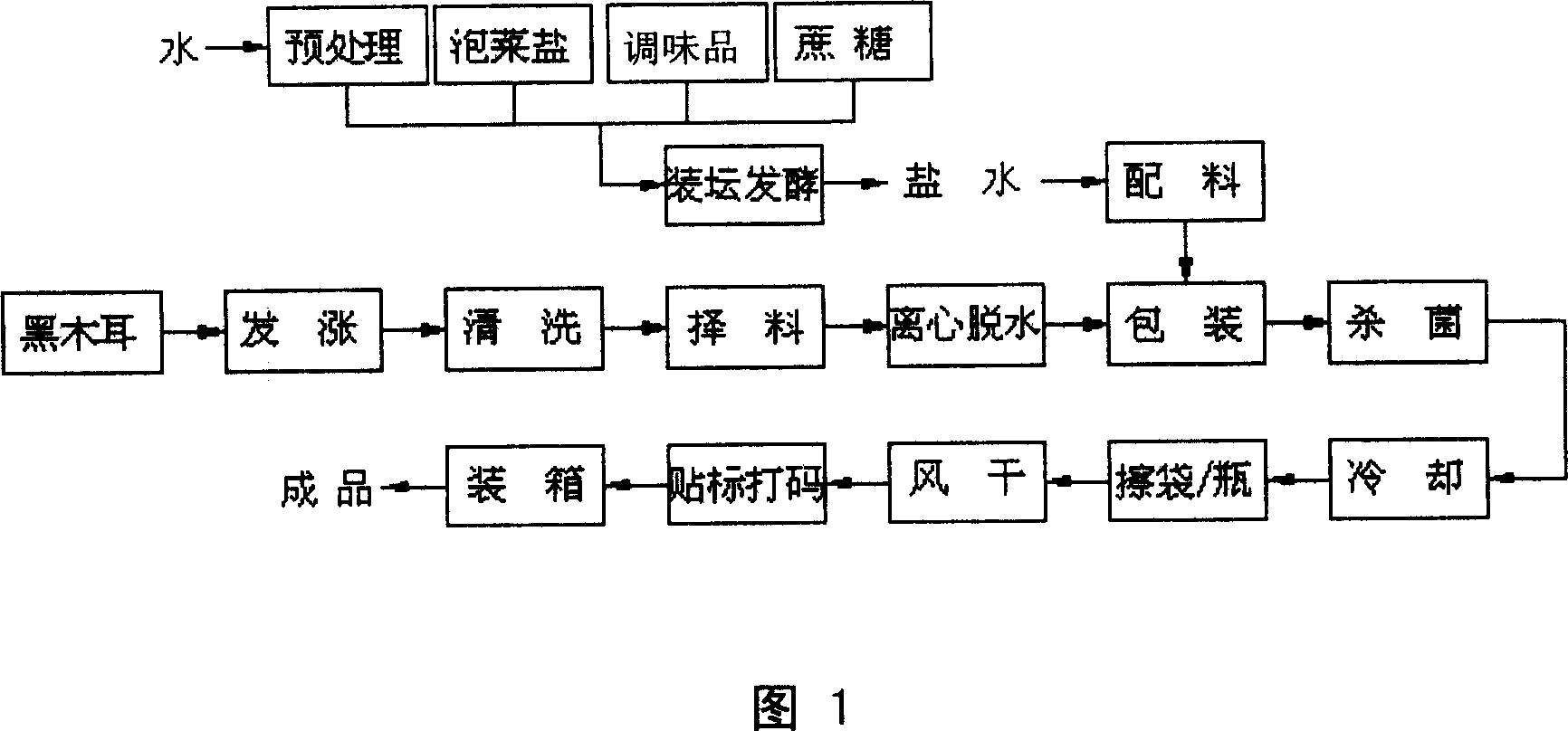

Image

Examples

Embodiment 1

[0023] 1. The making of salt water: adopt filter and sterilizer to process tap water into 100 kilograms of sterile process water, add 5ωt% pickle salt, 2ωt% sucrose, add 1ωt% condiment (capsicum, Chinese prickly ash, star anise and row grass) , packed into a kimchi jar for sealed fermentation, and fermented for 5 days at a temperature of 37° C. to obtain aseptic technical brine.

[0024] 2. Pretreatment of black fungus: first soak 100 kg of black fungus in 0.75ωt% sodium alginate for 1 hour, then rinse with water, soak in 1.5ωt% calcium chloride for 3 hours, and then rinse repeatedly with water. Eliminate impurities and dehydrate with a centrifuge.

[0025] 3. The black fungus processed by the above method is mixed with the prepared brine in a ratio of 1:2, and vacuum bottled.

[0026] 4. The packaged product is sterilized by pasteurization at a temperature of 85°C and a time of 30 minutes.

[0027] 5. Cool the sterilized product in sections, wipe off the moisture on the sur...

Embodiment 2

[0029] 1. The making of salt water: adopt filter and sterilizer to process tap water into 100 kilograms of aseptic process water, add the kimchi salt of 10ωt%, the sucrose of 5ωt%, add 2ωt% seasoning (capsicum, Chinese prickly ash, star anise and row grass) , put it into a kimchi jar for sealed fermentation, and make acid for 30 days at a temperature of 20° C. to obtain sterile process saline.

[0030] 2. Pre-treatment of black fungus: first soak 100 kg of black fungus in 0.5ωt% sodium alginate for 1 hour, then rinse with water, soak in 0.5ωt% calcium chloride for 3 hours, and then rinse repeatedly with water. Eliminate impurities and dehydrate with a centrifuge.

[0031] 3. The black fungus processed by the above method is mixed with the prepared brine in a ratio of 1:5, and vacuum bottled or bagged.

[0032] 4. Use the pasteurization method with a temperature of 95°C and a time of 25 minutes to sterilize the packaged products.

[0033] 5. Cool the sterilized product in sec...

Embodiment 3

[0035] 1. The making of salt water: adopt filter and sterilizer to process tap water into 100 kilograms of aseptic process water, add the kimchi salt of 8ωt%, the sucrose of 4ωt%, add the spices of 3ωt% (capsicum, Chinese prickly ash, star anise and row grass) , packed into a kimchi jar for sealed fermentation, and fermented for 3 days at a temperature of 37° C. to obtain aseptic technical brine.

[0036] 2. Pretreatment of black fungus: first soak 100 kg of black fungus in 1ωt% sodium alginate for 2 hours, then rinse with clean water, then soak in 2ωt% calcium chloride for 5 hours, then rinse repeatedly with clean water to remove impurities , dehydrated with a centrifuge.

[0037] 3. The black fungus processed by the above method is mixed with the prepared brine in a ratio of 1:3, and vacuum bottled or bagged.

[0038] 4. Sterilize the packaged products by pasteurization at a temperature of 90°C and a time of 30 minutes.

[0039] 5. Cool the sterilized product in sections, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com