Automobile control system

A hydraulic control valve and hydraulic braking technology, which is applied in the field of automobile control systems, can solve the problems of difficult control of braking amplitude, single control function, and difficult integration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

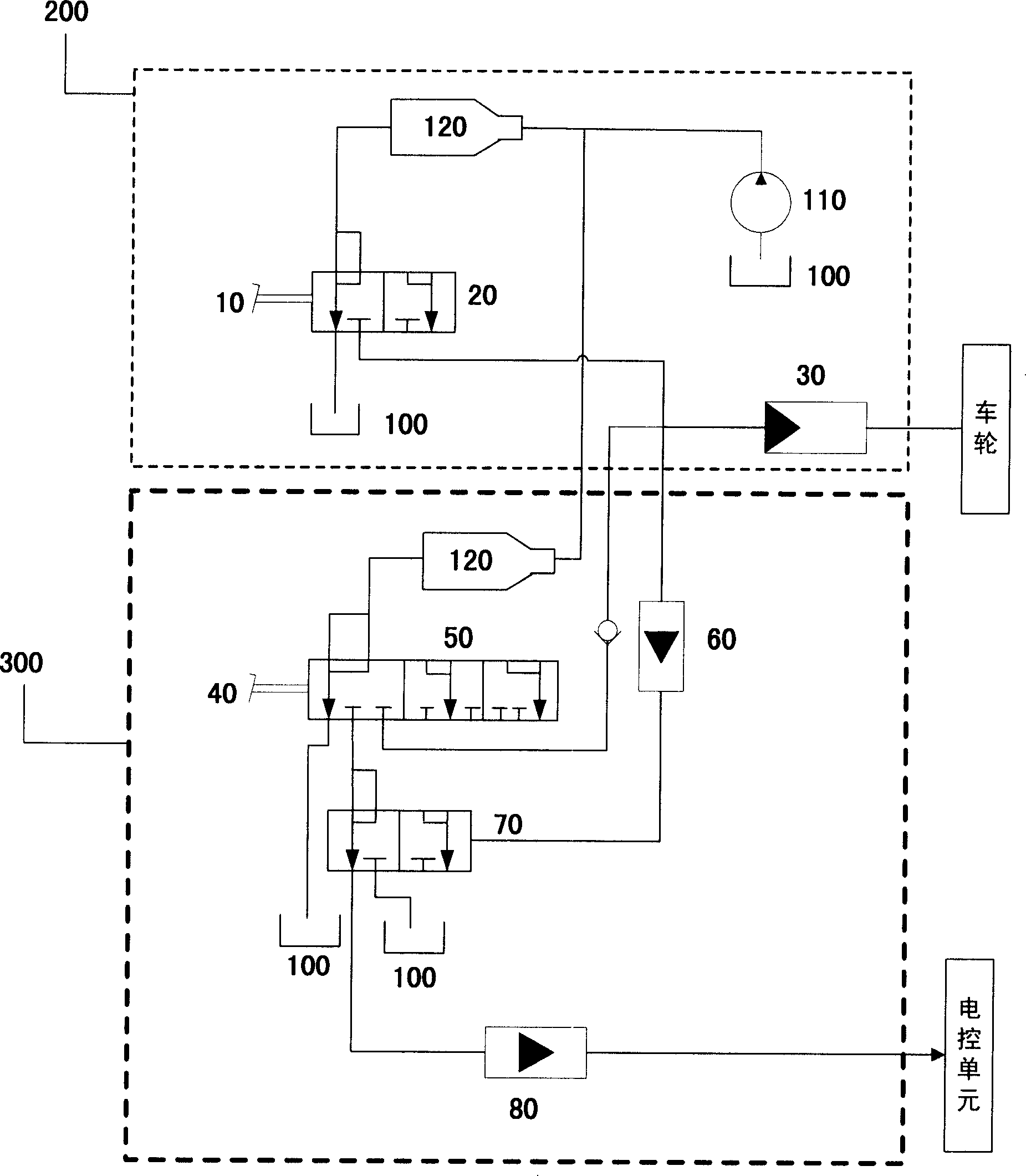

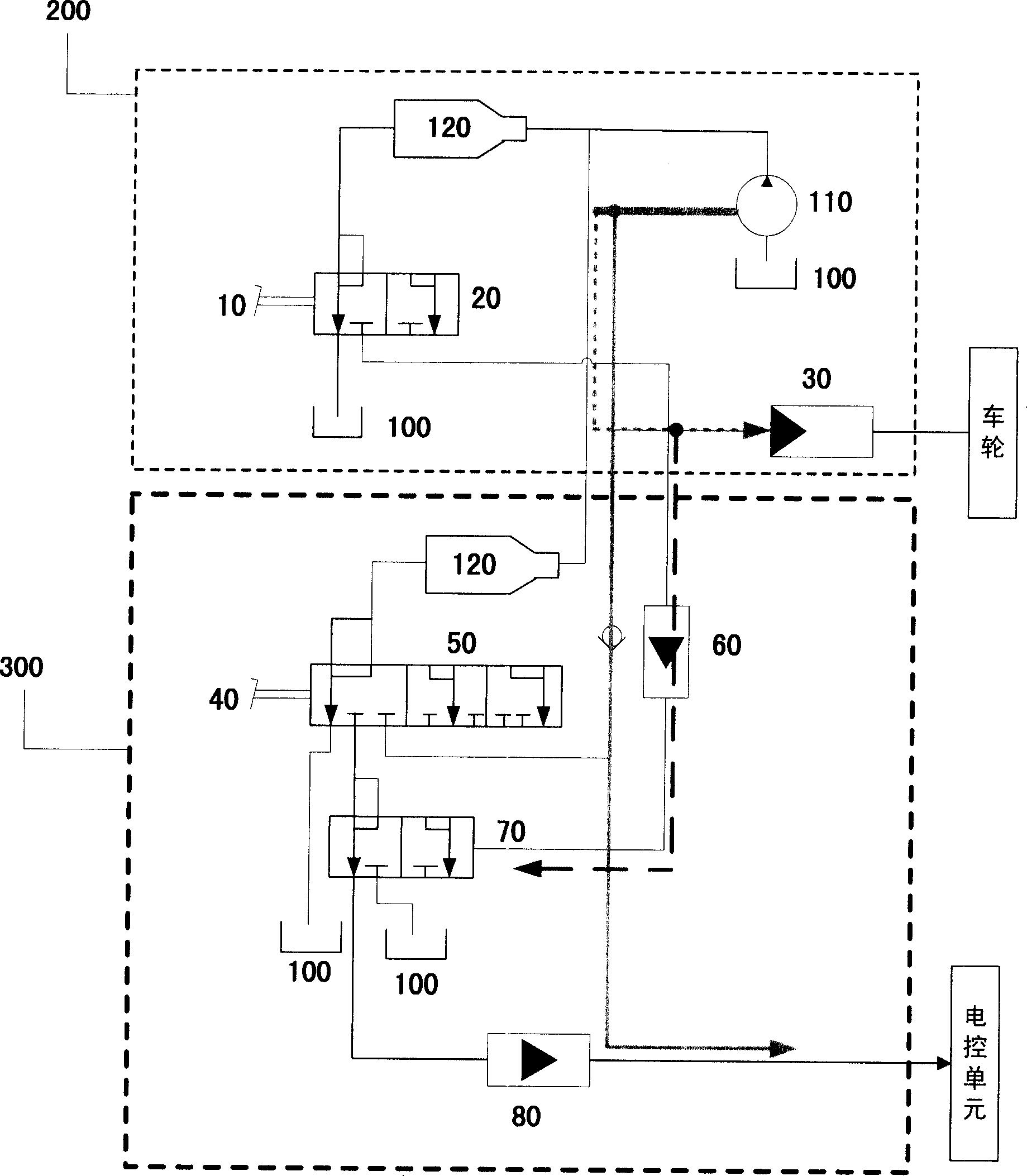

[0015] figure 2 A schematic diagram showing a vehicle control system according to the present invention. The vehicle control system includes a hydraulic acceleration unit 300 and a hydraulic braking unit 200, wherein the hydraulic acceleration unit 300 includes an accelerator pedal 40, a hydraulic control valve 50, a brake hydraulic pressure sensor 60, a solenoid valve 70, and an acceleration hydraulic pressure sensor 80, wherein the accelerator pedal 40 is mechanically connected to the spool of the hydraulic control valve, the first output position of the hydraulic control valve is connected to the hydraulic oil tank 100, the second output position of the hydraulic control valve is connected to the input position of the solenoid valve 70, and the hydraulic control valve The third output position of the solenoid valve 70 is connected to the inlet of the brake wheel cylinder 30 of the hydraulic brake unit 200, the first output position of the solenoid valve 70 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com