Battery connecting wafer structure

A battery connecting piece and battery technology, which is applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of liquid leakage, reduced adhesion, unstable configuration of the electrode cover 25, etc., to avoid displacement, protect adhesion, and buffer. Effects of inter-cell stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

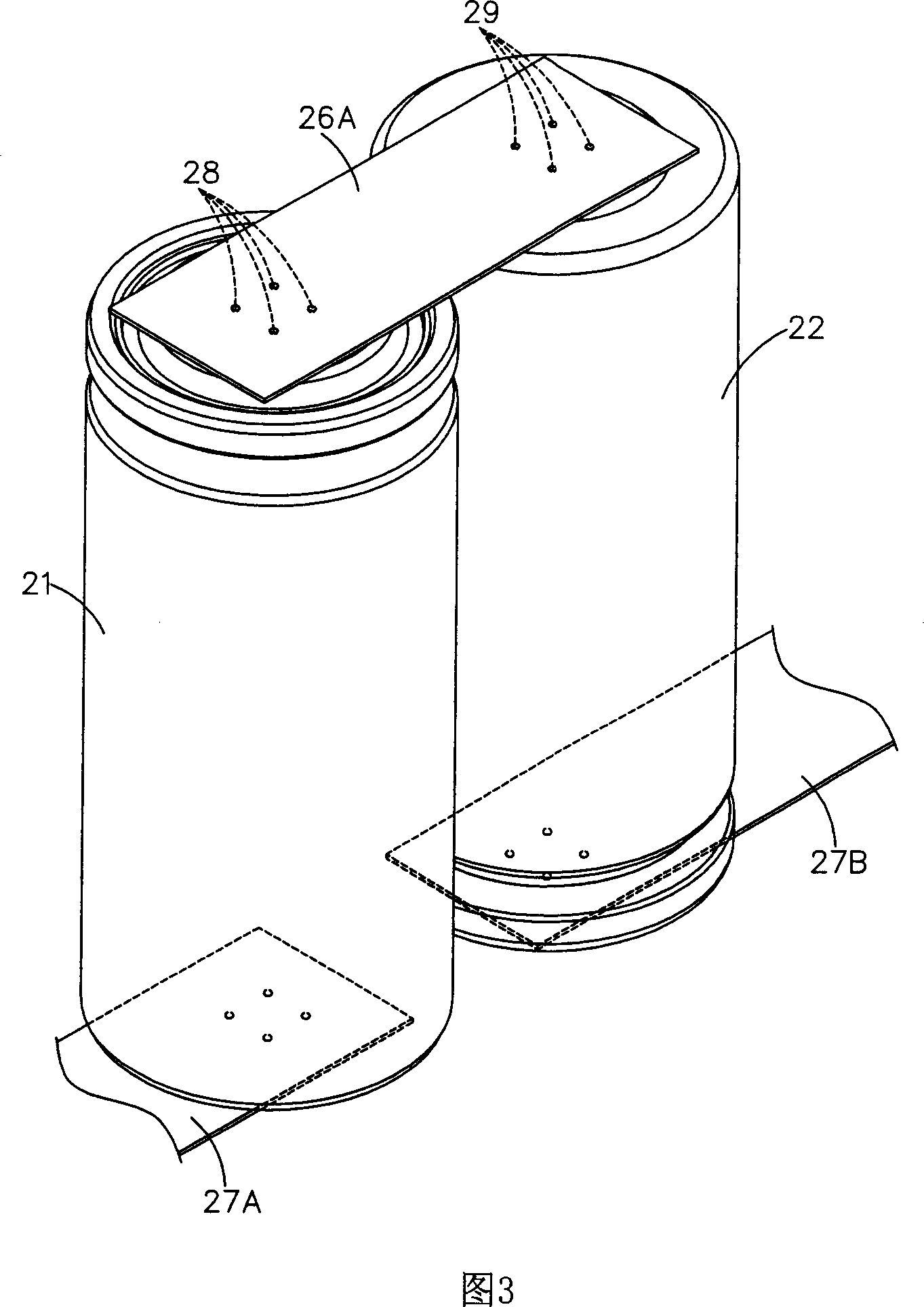

[0053] In order to clearly describe the structure and function of the present invention, the embodiments of the present invention will be described in detail below with reference to the drawings.

[0054]Please refer to FIG. 5 , which shows a battery connecting piece according to an embodiment of the present invention. The present invention provides an integrally formed battery connection sheet structure, which includes at least one bent portion 51 and connecting portions 52A, 52B connected to both sides of the bent portion 51, please refer to FIG. 6A, which is the battery connection in FIG. 5 The side view of the sheet fixed on the battery A, B, the battery connection sheet is fixed on the electrode cover 55 by the connection part 52A, 52B through the welding point 58, and in Fig. 6B, it shows that this embodiment can be used for both batteries at the same time end link.

[0055] Please refer to FIG. 7, which shows the variation of the embodiment of the present invention in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com