Magnetic steel disc classifier

A magnetic steel sheet and sorting machine technology, used in solid separation, wet separation, sieve and other directions, can solve the problems of collision, low product qualification rate, edge damage of magnetic steel sheet, etc., and achieve obvious economic benefits and screening process. Extend and reduce the effect of collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

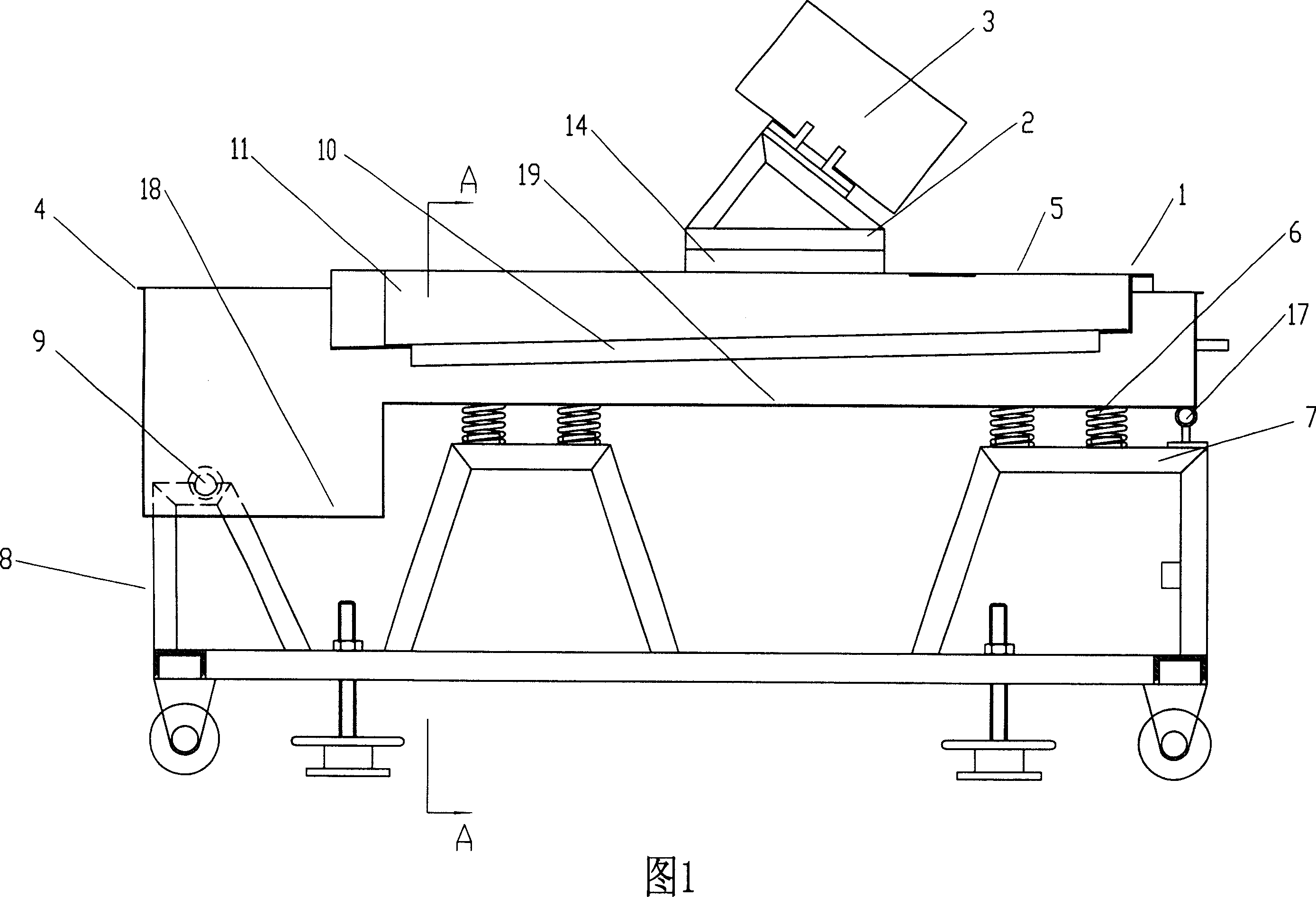

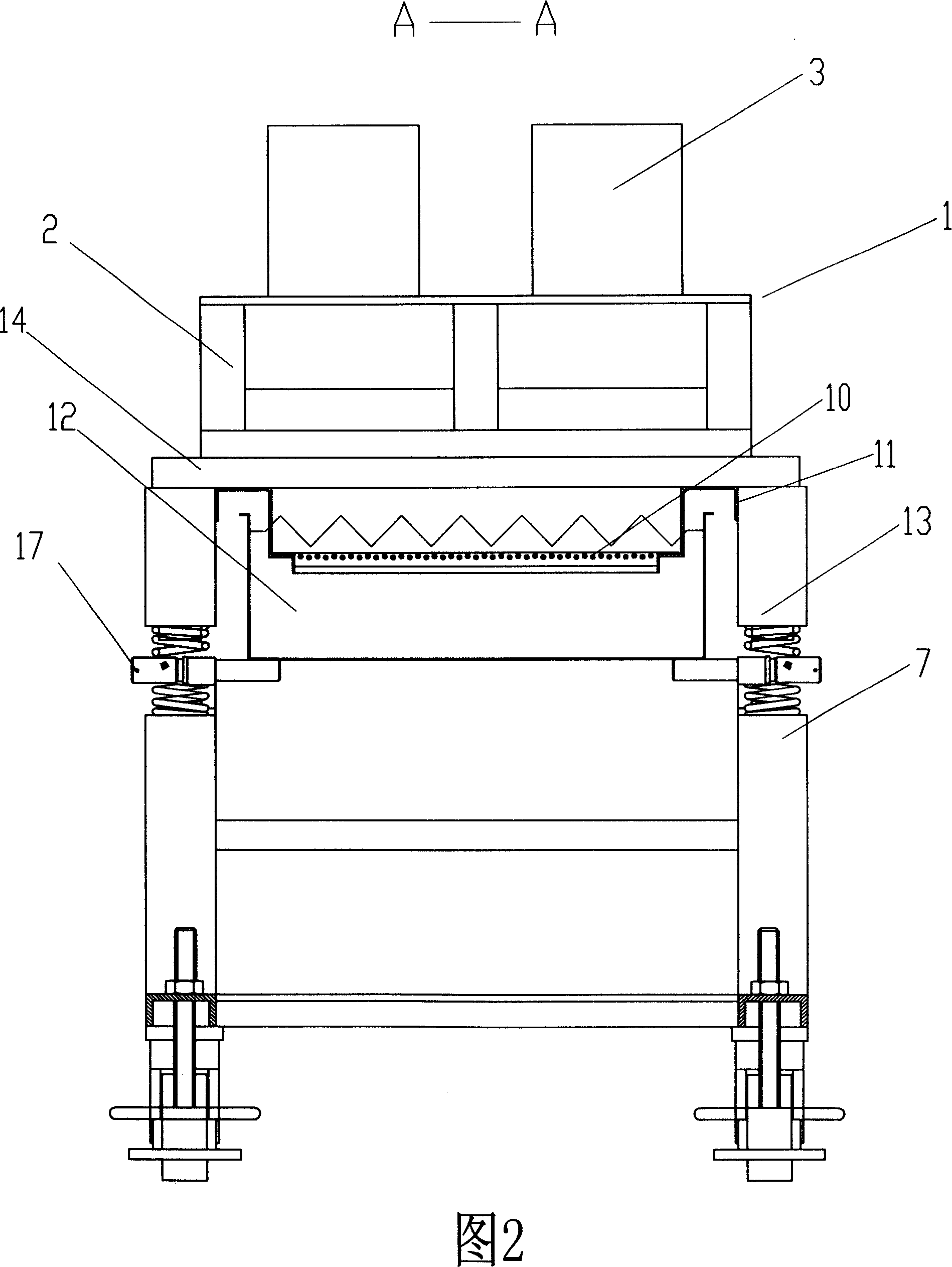

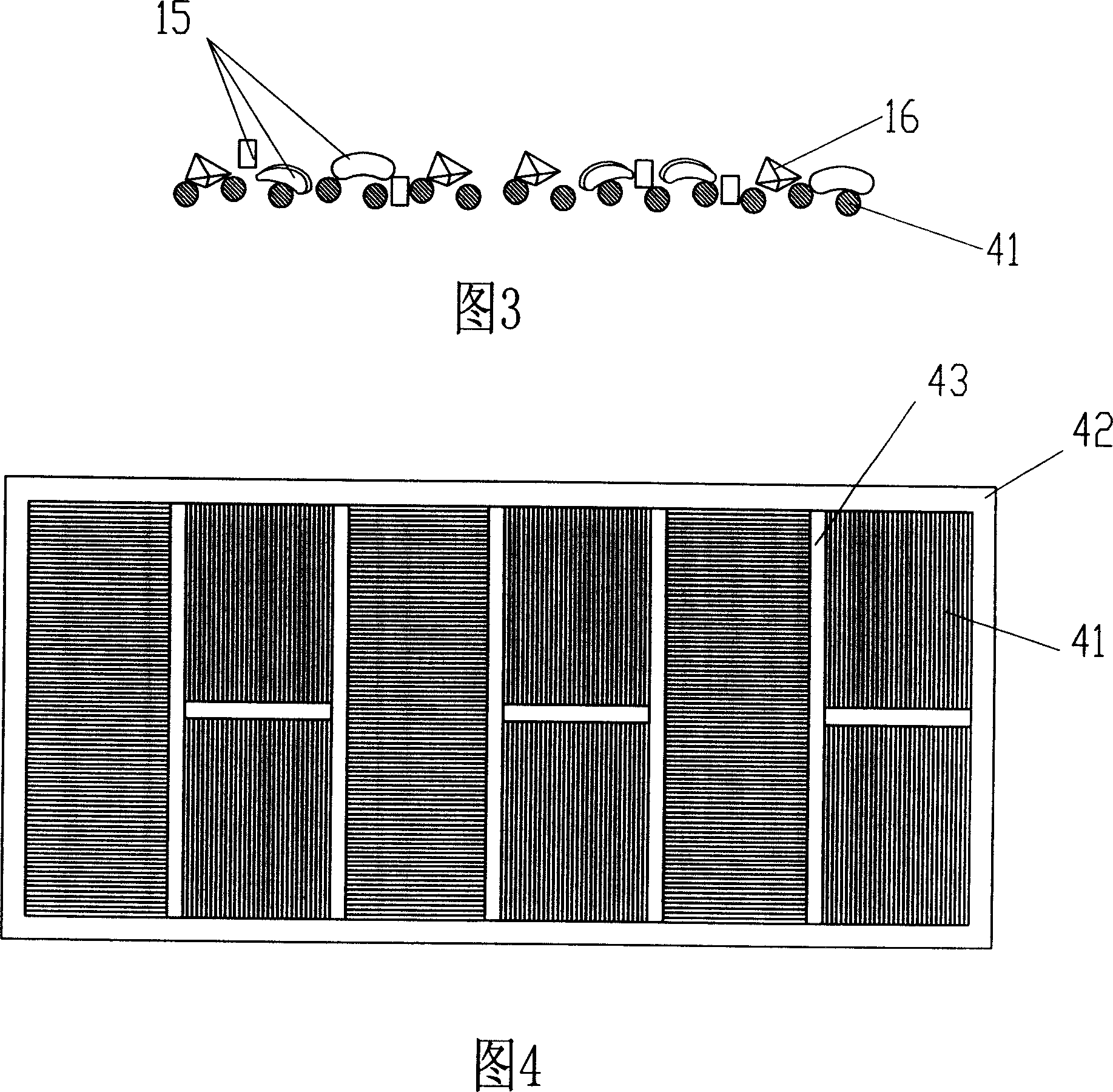

[0012] The magnetic steel sheet separator is mainly a separation device for separating obtuse and acute-angle NdFeB magnetic steel sheet products and mixing with polygonal abrasives for vibrating and rolling. It is to ensure that the magnetic steel sheet products are separated on the vibrating screen. Softer, less broken corners, less cracks, so as to ensure the qualified rate of finished products of magnetic steel sheet products, so that the qualified rate of magnetic steel sheet products is always stabilized within a relatively constant index range. The magnetic steel sheet sorting machine designed by the present invention immerses the screen and the sorted objects in the liquid storage receiving box filled with liquid to carry out vibration sorting, so that the liquid can act as a buffer and reduce the direct friction between the magnetic steel sheet and the abrasive , reduce the damage of the magnetic steel sheet caused by direct hard collision, and improve the qualified ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com