Pressing roller holder for stretching structure

A technology of press roller support and double press rollers, which is applied in drafting equipment, spinning machines, textiles and papermaking, etc., can solve the problems of troublesome manufacturing process, and achieve the effect of economical manufacturing cost and simplified processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

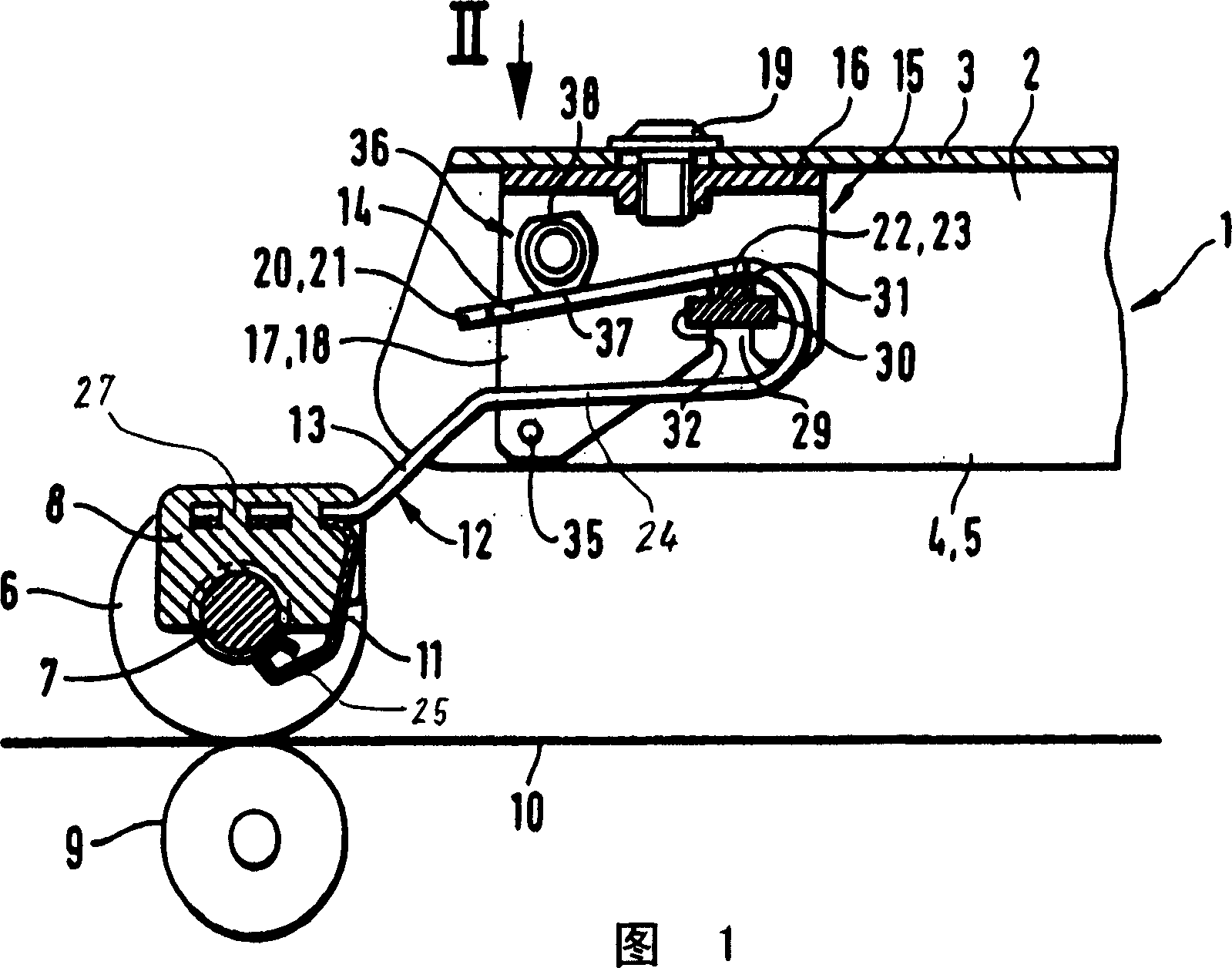

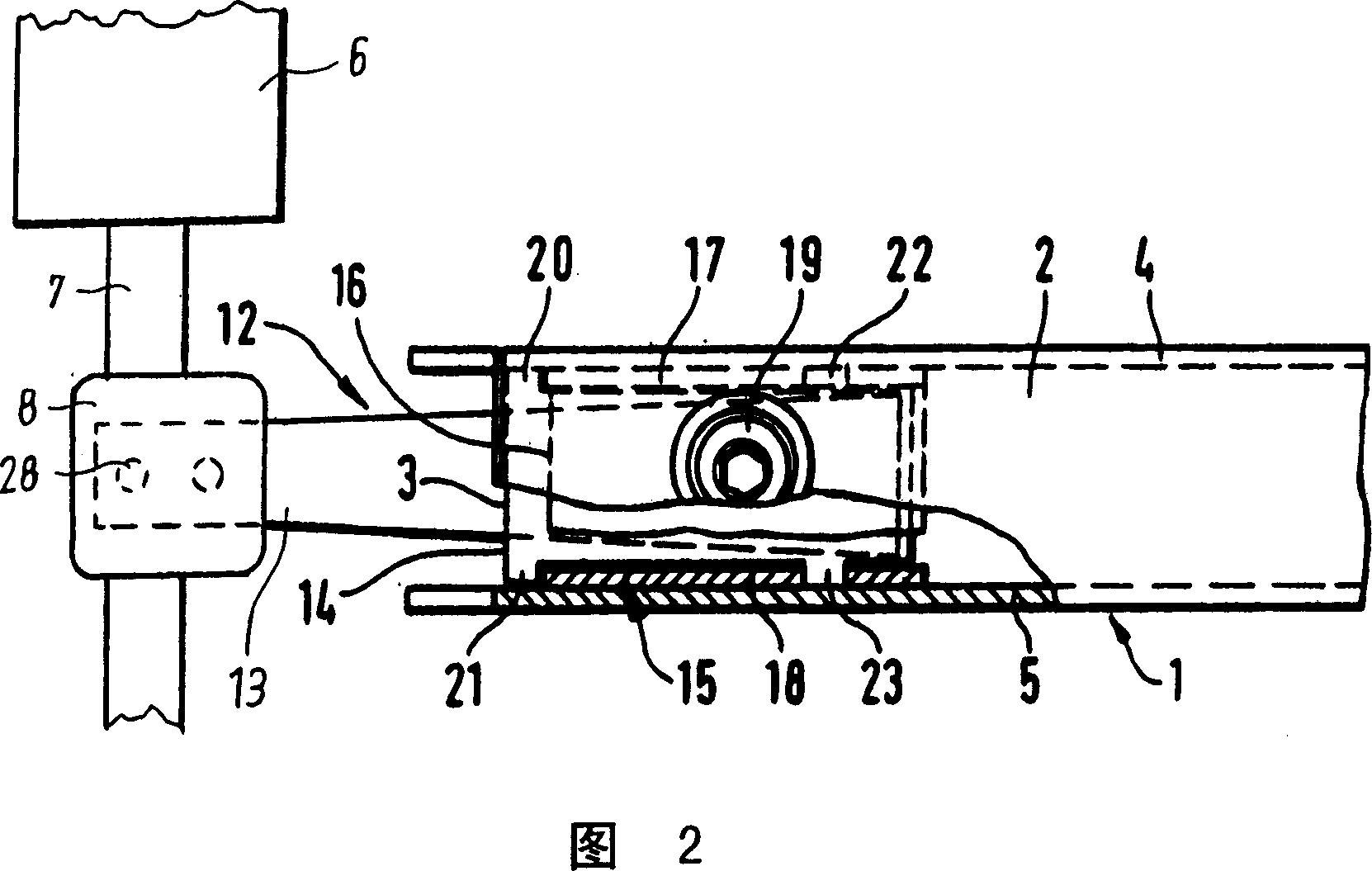

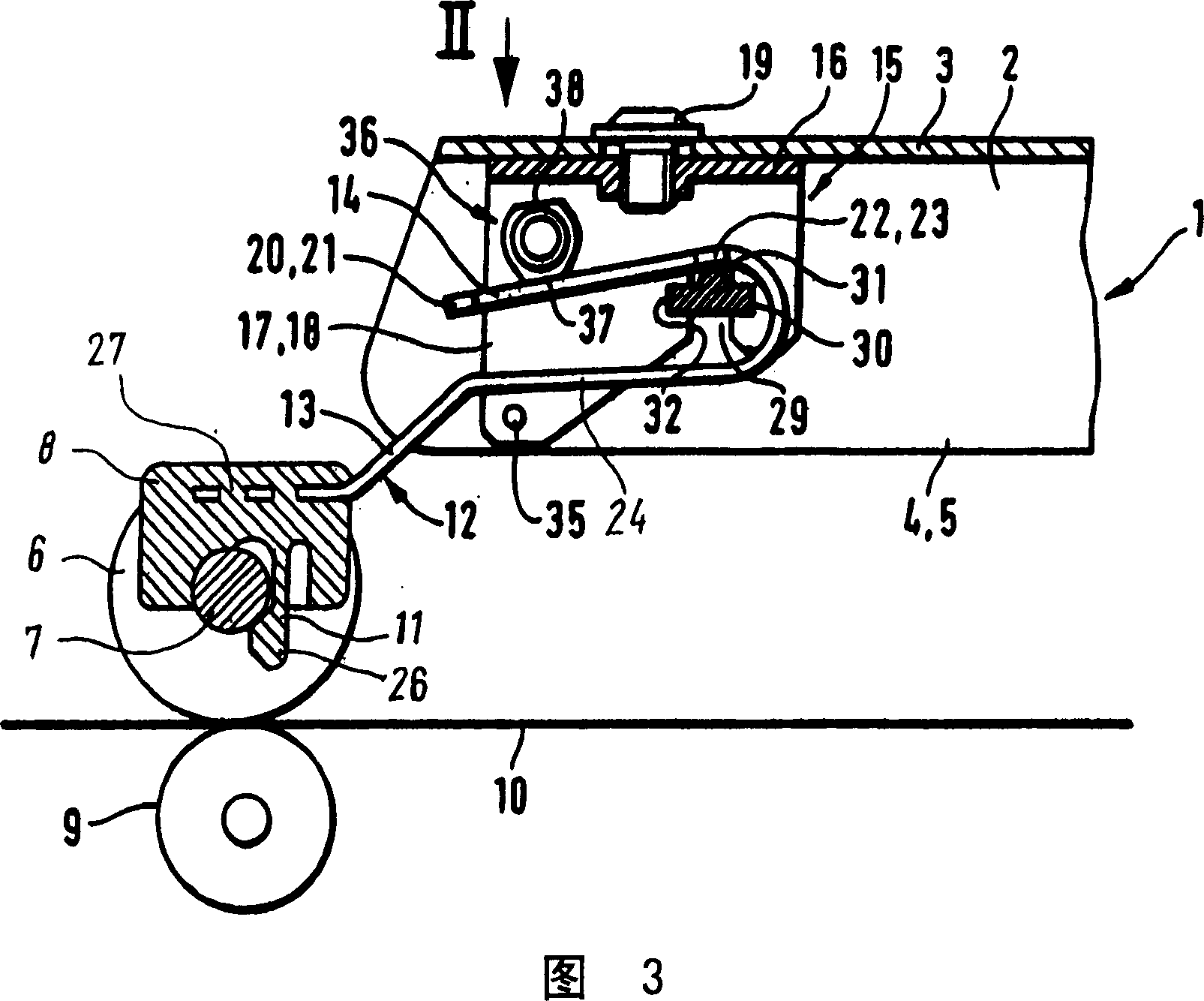

[0016] 1 and 2 partially show a drafting mechanism, in particular a load arm 1 of a drafting mechanism for a ring spinning machine. The load arm 1 has a U-shaped profile 2 . The load arm is supported at its not-shown end on a support rod parallel to the lower rollers of the drafting mechanism, one of which is shown here as the lower roller 9 . The load arm 1 is guided on a support rod and is rigidly constructed such that it can pivot in a plane perpendicular to the lower roller 9 . The load arm 1 supports a plurality of upper rollers in the form of double pressure rollers 6 , of which only one double pressure roller 6 is shown, and which are allocated in corresponding numbers to the lower rollers. The double pressure roll 6 comprises two roller core top rollers which are supported on a common roller shaft 7 and which is clamped between these two roller core top rollers. The fiber strands 10 run between each upper and lower roll 9 of the double pressure rollers 6, and the fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com