Optical module and making method thereof

A technology for a backlight module and a manufacturing method, applied in optics, nonlinear optics, instruments, etc., can solve problems such as easy loosening, and achieve the effect of improving rigidity and enhancing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

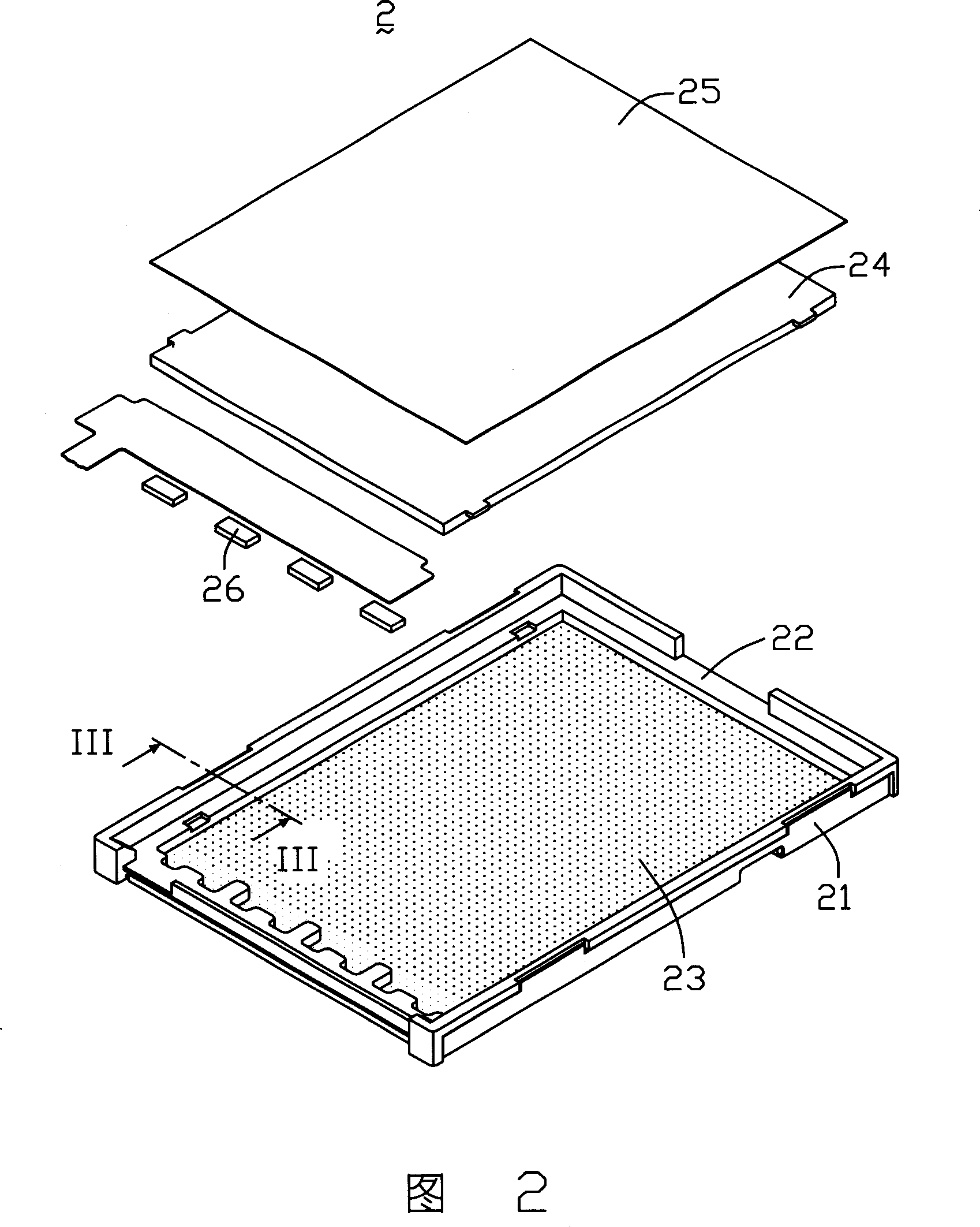

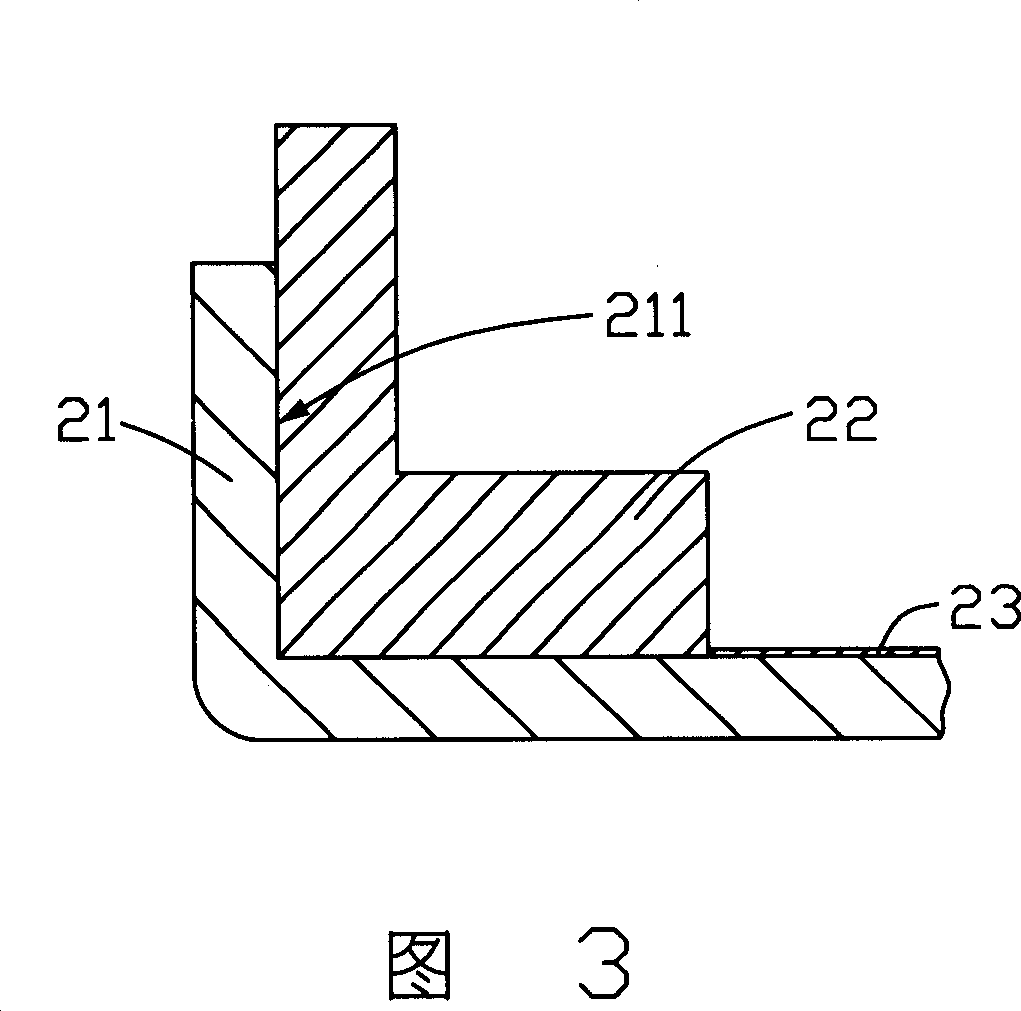

[0015] The backlight module of the present invention is shown in FIG. 2 and FIG. 3 , FIG. 2 is an exploded view of the backlight module 2 , and FIG. 3 is a sectional view along III-III of the backlight module 2 shown in FIG. 2 . The backlight module 2 includes a metal back plate 21 having an inner bottom surface (not shown) and an inner wall 211, a plastic frame 22, a reflective layer 23 plated on the inner bottom surface of the metal back plate 21, a light guide plate 24, and a diffuser located above the light guide plate 24. plate 25 and a light source 26 adjacent to one end of the light guide plate 24 . The plastic frame 22 is integrally formed with the metal backboard 21 , and the plastic frame 22 covers the inner wall of the metal backboard 21 . The light guide plate 24 is located above the metal back plate 21 . The metal backplane 21 can be an aluminum backplane. The plastic frame is made of polycarbonate material. The reflective layer can be made of metal with high r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com