Resonance eddy detection method for surface crack

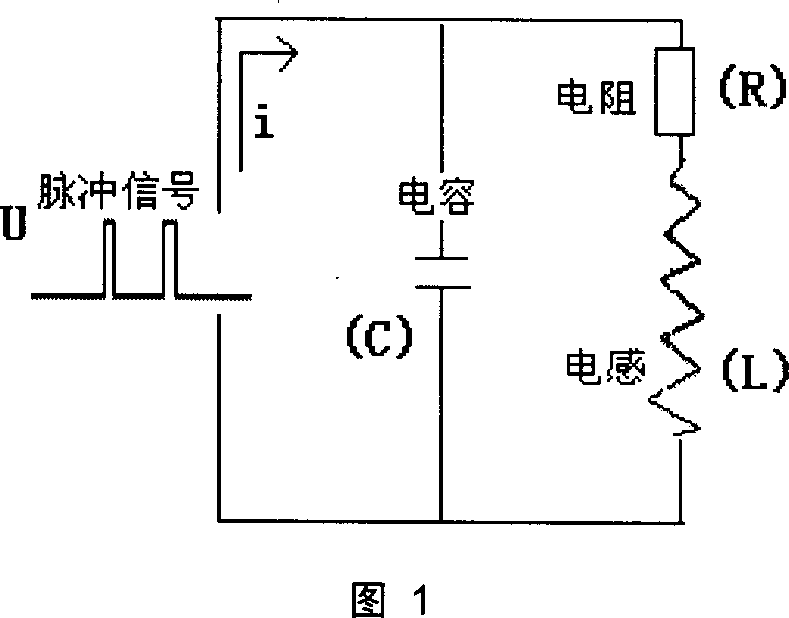

A detection method and technology for surface cracks, applied in the direction of material magnetic variables, etc., can solve problems such as difficult surface crack detection, and achieve the effect of simple processing and easy design of portable detection instruments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

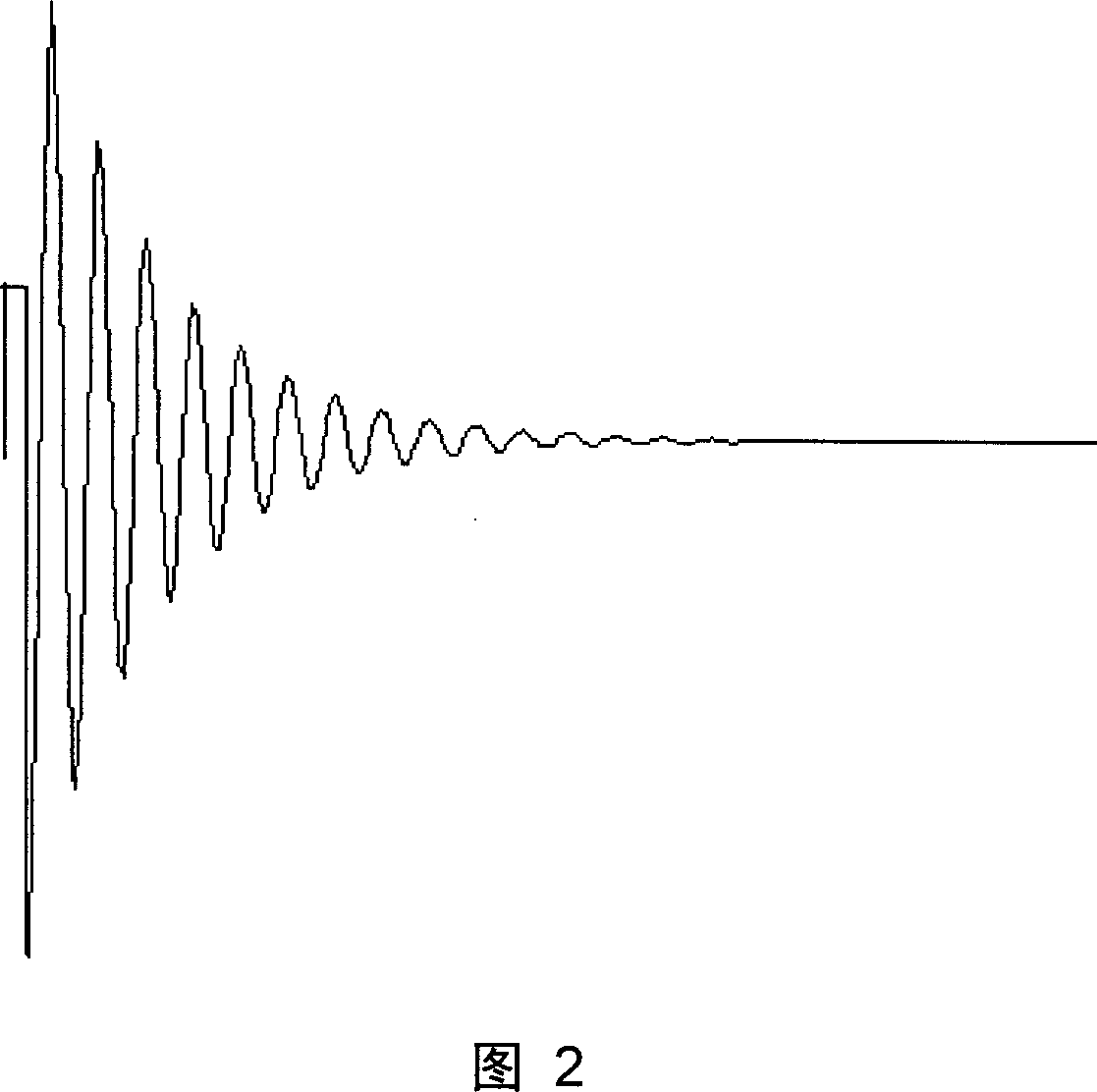

Method used

Image

Examples

Embodiment 1

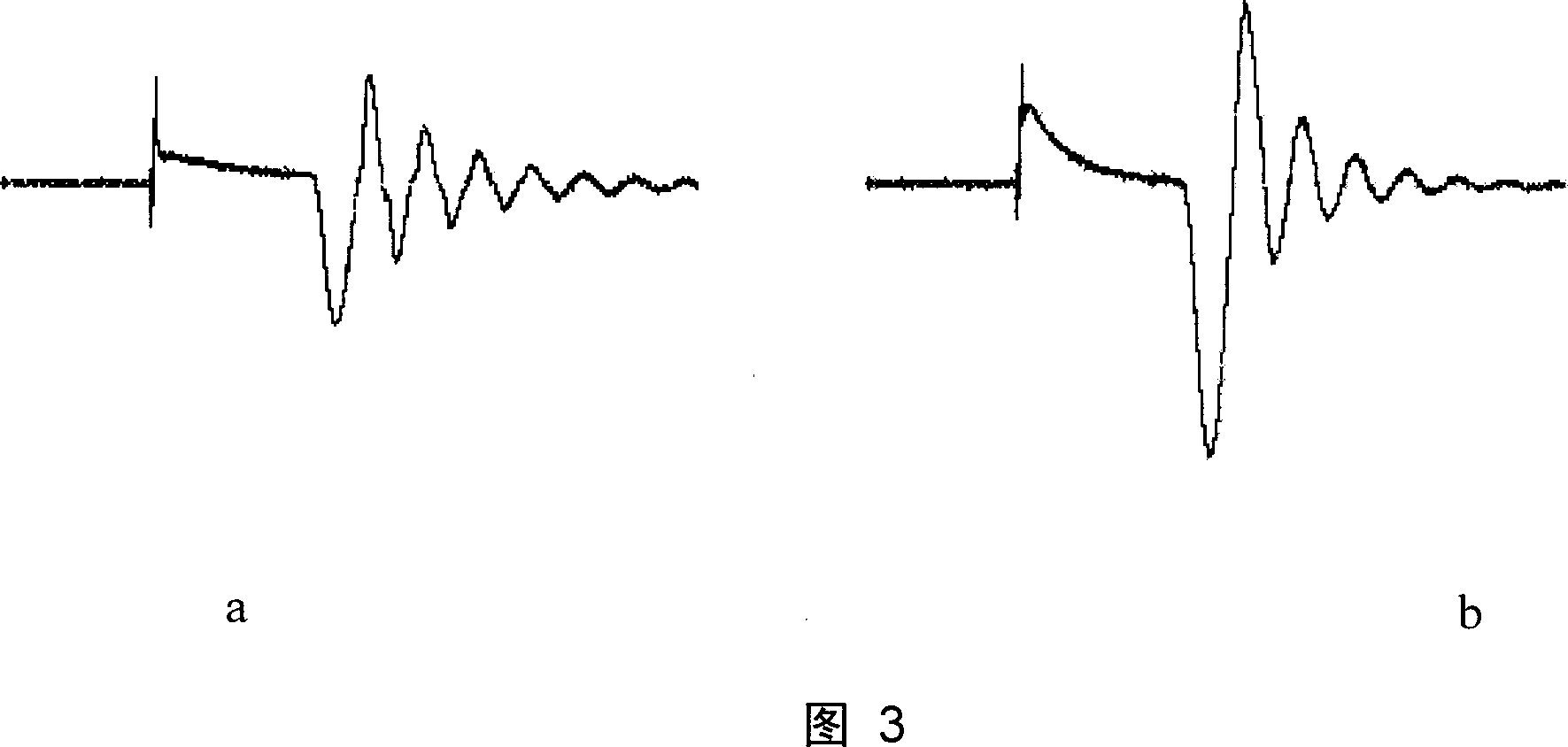

[0043] (1) Detect crack width of 0.3mm, depth of 2mm, 1mm, 0.5mm standard eddy current testing crack samples

[0044] (2) The sensor probe sweeps across the crack at a speed of 0.5m / s, and the lift-off height is 2.5mm

[0045] crack size

Embodiment 2

[0047] (1) The detection crack width is 0.9mm-1.5mm continuous change, and the length is 150mm. The crack in the groove of the wheel hub is 2-3mm putty and anti-rust paint attached to the surface of the hub groove, and the surface is rough.

[0048] (2) The sensor probe sweeps across the crack at a speed of 2.5m / s, and the lift-off height is 4.5mm

[0049] no defect

Embodiment 3

[0051] (1) The detection crack width is 0.9mm-1.5mm continuous change, and the length is 150mm. The crack in the groove of the wheel hub is 2-3mm putty and anti-rust paint attached to the surface of the hub groove, and the surface is rough.

[0052] (2) The sensor probe sweeps across the crack at a speed of 1.5m / s, and the lift-off height is 6.5mm

[0053] no defect

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com