Method for determining rotating speed of main shaft expanded by cold rolling

A technology of spindle speed and rolling, applied in the field of cold rolling of rings, can solve the problems of lack of scientific basis, long process cycle of new products and high cost, and achieve the effect of shortening process cycle, reducing the number of tests and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

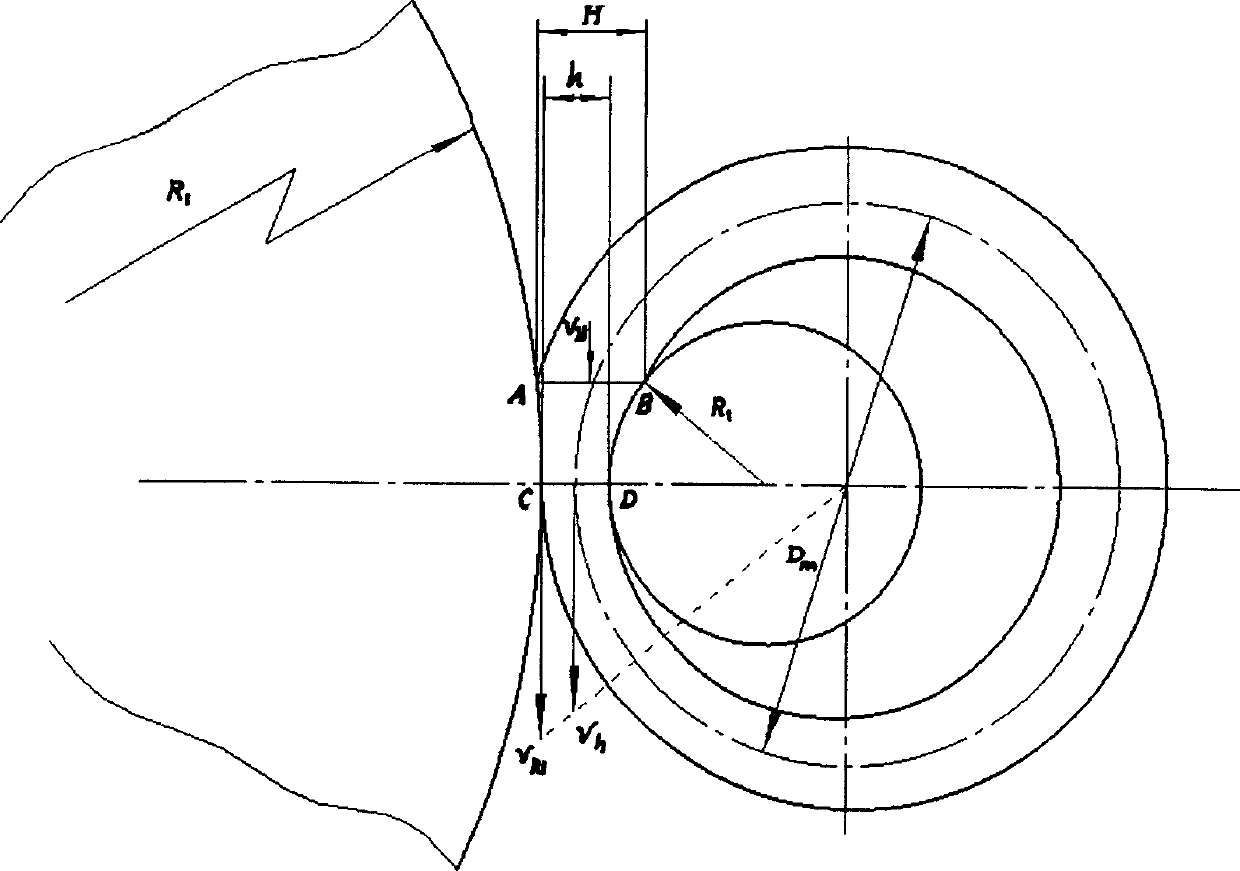

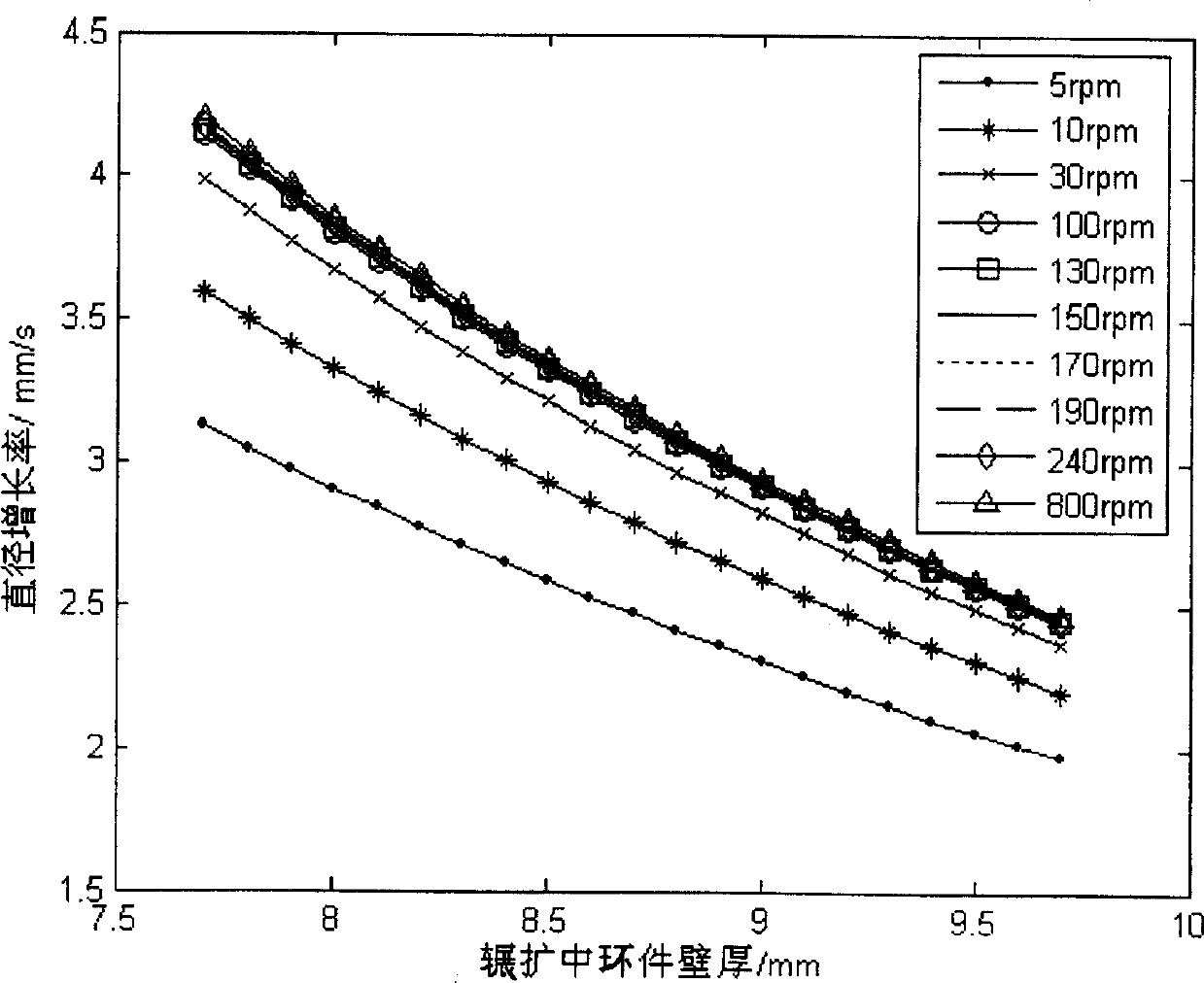

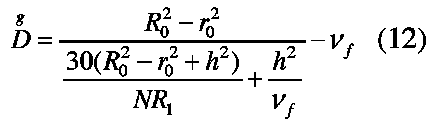

[0043] Ring blank size is: R 0 =33.6mm, r 0 =23.9mm, radius R of the main roller 1 =103.61mm, v f =2mm / s, the wall thickness of the ring blank is 9.7mm, and the wall thickness of the finished ring is h min =7.7mm, when rotating speed N (unit: rpm) is 5, 10, 30, 100, 130, 150, 170, 190, 240, 800 respectively, bring into formula (12), get diameter growth rate with respect to spindle speed and rolling graphs of the wall thickness of the rings in the process, which are a set of curves such as figure 2 shown. It can be seen from the figure that when the speed is above 150rpm, the five curves basically overlap (the relative difference of the diameter growth rate corresponding to two adjacent curves at the same wall thickness is within 1%), and 150rpm is the most reasonable as the spindle speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com