Process for the manufacture of 2,3-dichloropyridine

A technology of dichloropyridine and chloropyridine, applied in the field of preparation of 2,3-dichloropyridine, which can solve the problems of limited scale limitation and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach A

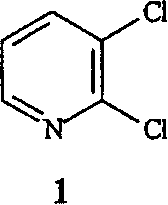

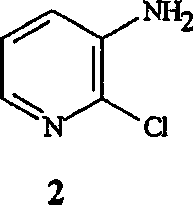

[0024] Embodiment A. Process for the preparation of 2,3-dichloropyridine 1 (Process A),

[0025]

[0026] Including the following steps:

[0027] (1) contacting a solution comprising 3-amino-2-chloropyridine 2 with a first aqueous solution comprising hydrochloric acid to form 3-amino-2-chloropyridine hydrochloride;

[0028]

[0029] (2) contacting the 3-amino-2-chloropyridine hydrochloride with an aqueous solution comprising nitrite to form a diazonium salt; and

[0030] (3) Contacting the diazonium salt with an aqueous solution comprising a Cu(II) salt in the presence of a second aqueous solution comprising hydrochloric acid, optionally in the presence of an organic solvent, to form 2,3-dichloropyridine 1 .

Embodiment approach 1

[0031] Embodiment 1. The method of Embodiment A wherein the nitrite is sodium nitrite.

Embodiment approach 2

[0032] Embodiment 2. The method of Embodiment A wherein the Cu(II) salt is copper(II) chloride or copper(II) oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com