Semiconductor device

A technology for semiconductors and devices, applied in the field of semiconductor devices, can solve the problem of inability to obtain the resistance ratio, and achieve the effects of accurate resistance ratio, stable resistance ratio, and preventing the increase of manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

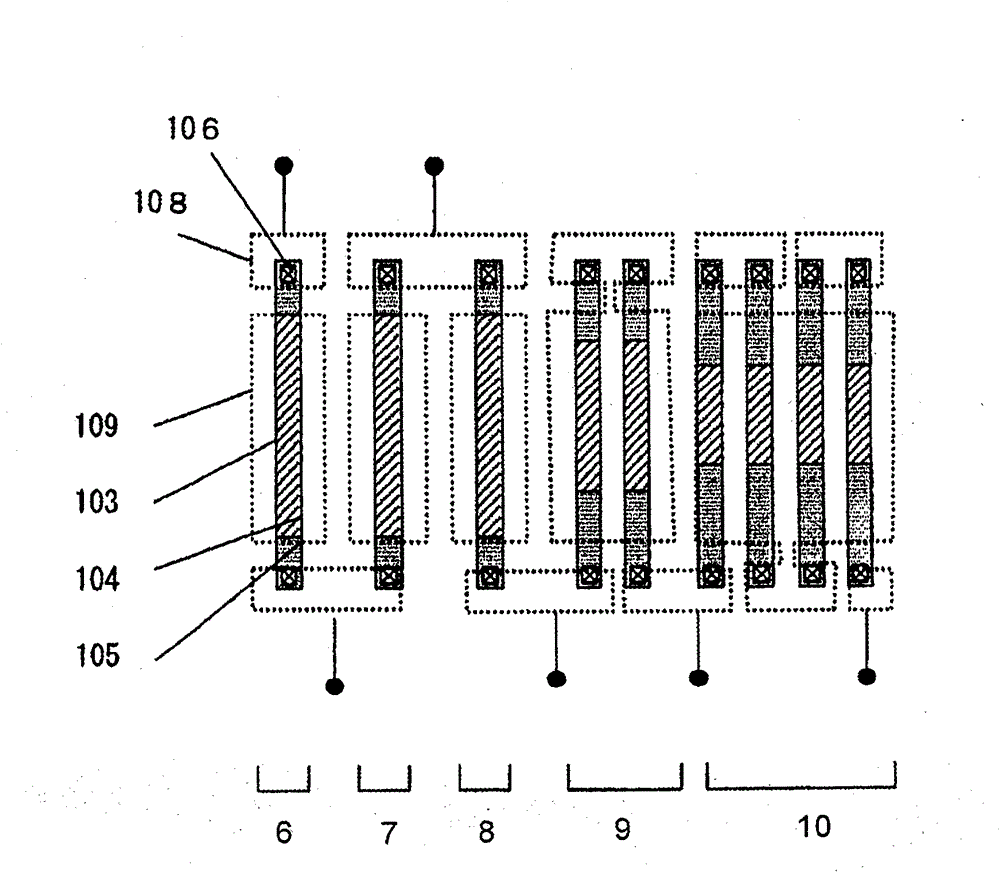

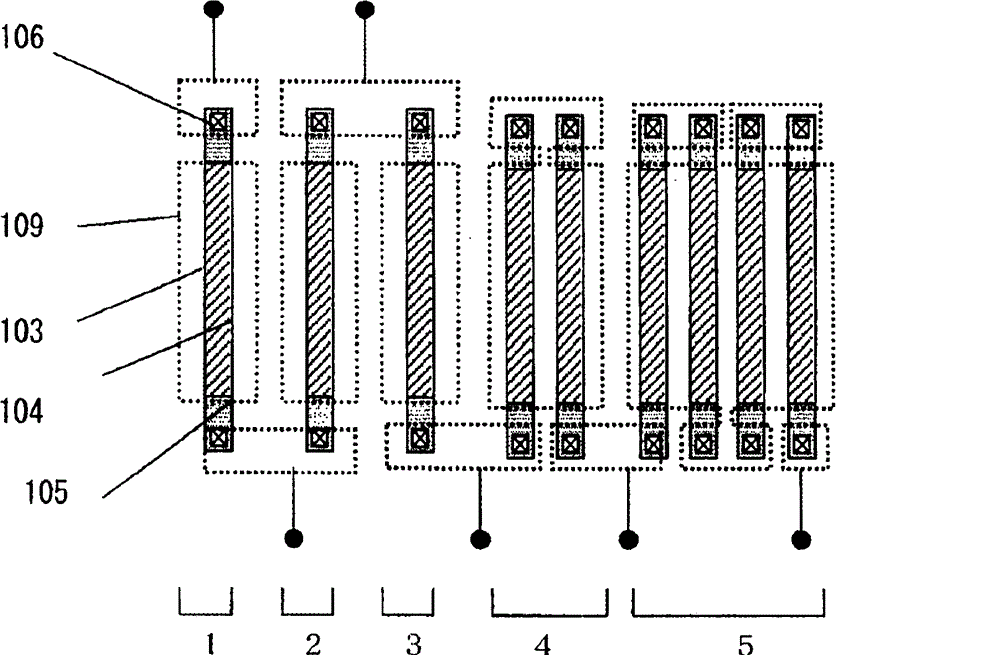

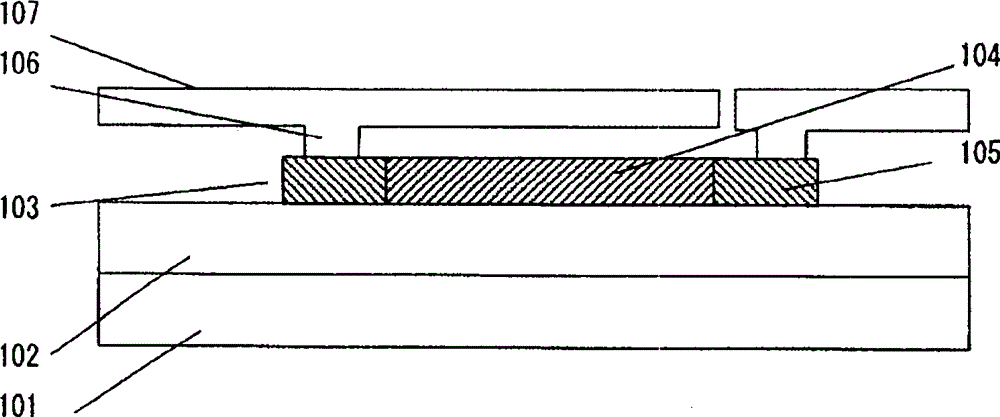

[0026] image 3 Showing a 50 µm increase in the area of the second metal part 2 Increased the resistance ratio by 1%. This establishes the expression described below.

[0027]Assuming that the resistance ratio desired to be increased is a%, the area of the second metal portion is A, the area of the low-concentration impurity region before changing the area is B, and the area of the low-concentration impurity region changed to change the resistance ratio is X1. To increase the resistance ratio by a%, multiply 50 by a and add to A. However, the area of the second metal portion is not changed in the present invention. Therefore, the equation (A+50·a):B=A:X1 holds true, and X1 is expressed by the equation X1=A·B / (A+50·a). Further, in the present invention, the length L of the low-concentration impurity region in the longitudinal direction is changed, thereby changing the area. When the area of the low-concentration impurity region is expressed as the equation X1=(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com