Sartorius

A sewing machine and bottom plate technology, which is applied in the field of sewing machines, can solve problems such as malfunction, entry into the motor installed on the bottom plate frame, and decreased accuracy of rotation position detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

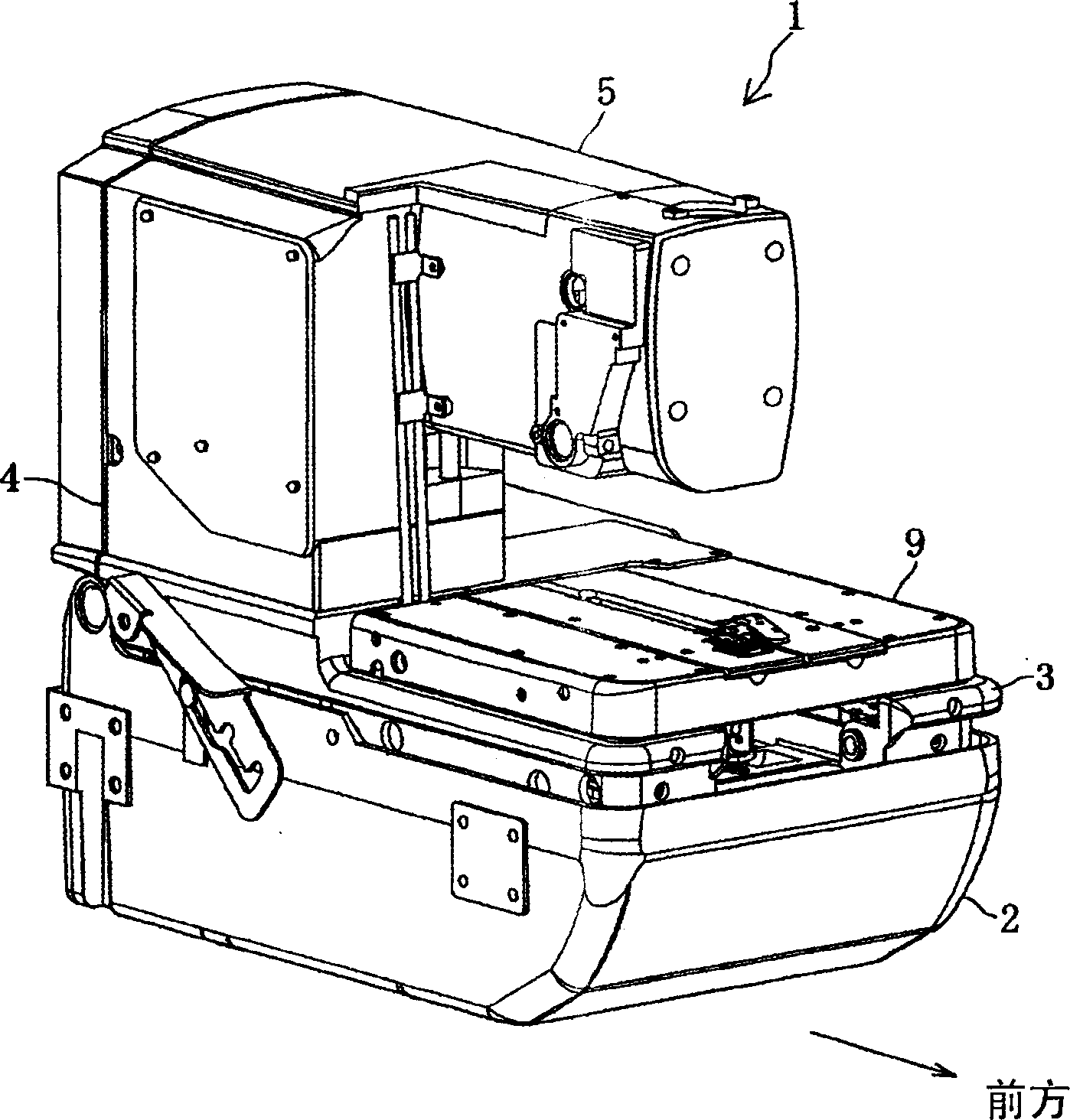

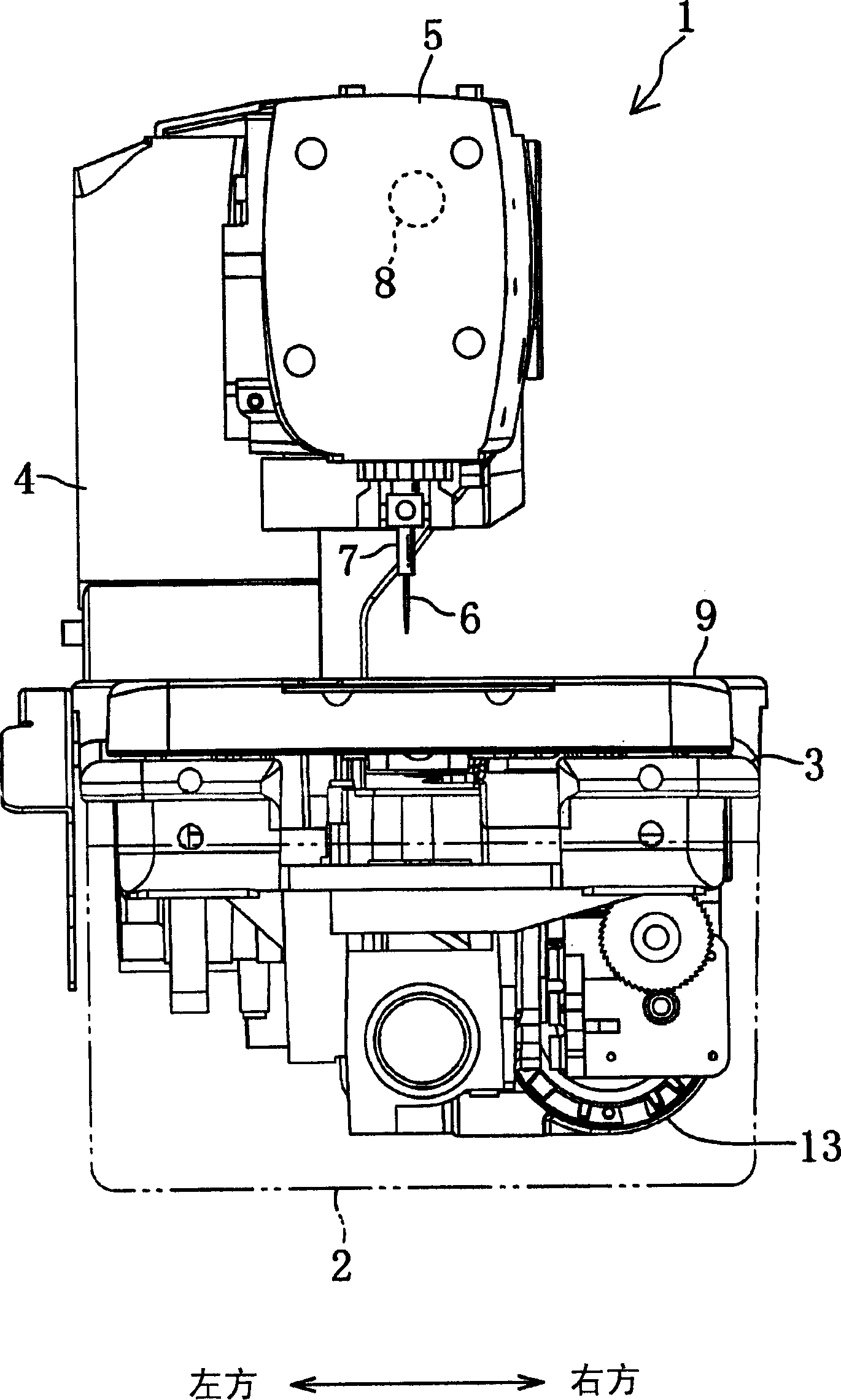

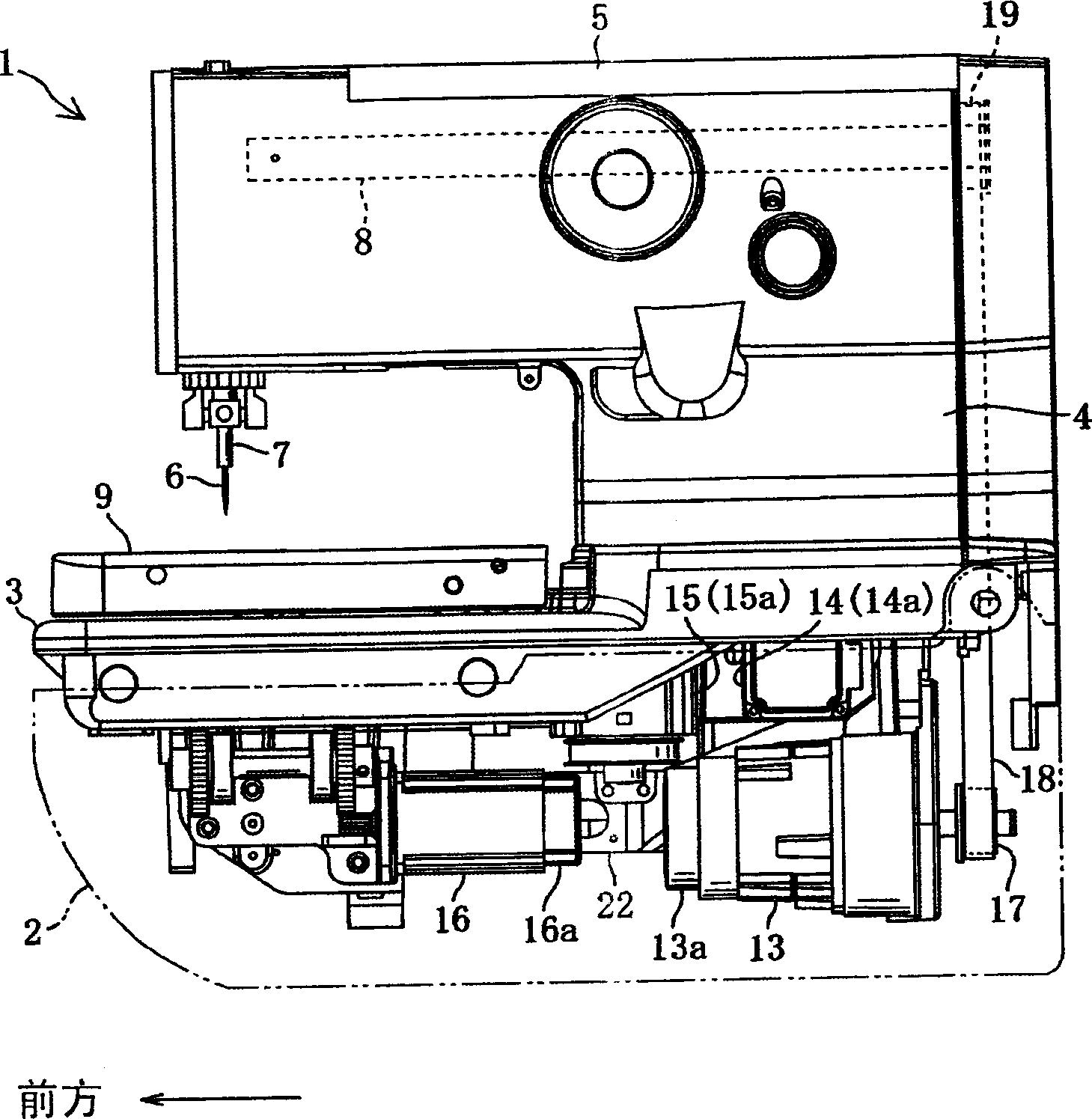

[0030] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0031] In the sewing machine of the present invention, that is, the eyelet buttonhole sewing machine shown in the figure, a partition wall is formed under the base frame to surround the discharge hole provided at the connection portion between the base frame and the column, The used lubricating oil leading out from the lower part of the frame is blocked and prevented from entering the motor arrangement area where the electric motor is arranged.

[0032] The buttonhole sewing machine 1 which is the sewing machine of the present invention will be described.

[0033] Such as Figure 1 ~ Figure 3 As shown, the round head buttonhole sewing machine 1 includes: a rectangular box-shaped machine base 2 with the upper part fully open, a base frame 3 embedded in the open part of the base 2, and a column 4 erected from the rear of the base frame 3 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com