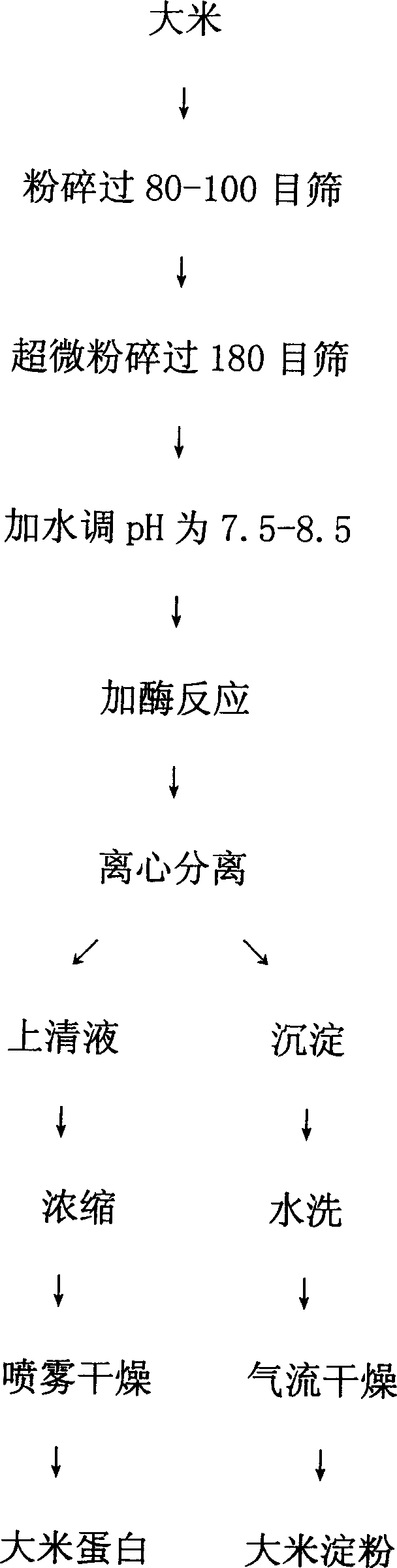

Process for preparing rice starch and rice protein

A rice protein and rice starch technology, applied in the field of rice deep processing, can solve the problems of low comprehensive utilization level of by-products, single structure of rice processed products, etc., and achieve the effects of small protein residue, high purity and high nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 15kg of rice flour that has been ultrafinely pulverized and passed through a 180-mesh sieve, add 90L of water, stir and mix well, heat to 50°C, add 30g (20U / g) of 2709 alkaline protease, and perform enzymatic hydrolysis for 8 hours. The reaction temperature is controlled at 50-55°C Centrifugal separation after the enzymolysis reaction, the precipitate was washed once with 60 L of water, and air-dried to obtain 7 kg of rice starch, so that the water content was below 12%. The supernatant was concentrated to 20%-25% solids. Then the concentrated feed liquid is spray-dried to obtain 1.2 kg of rice protein product, so that the moisture content is below 5%.

Embodiment 2

[0026] Take 15kg of rice flour that has been ultrafinely pulverized and passed through a 180-mesh sieve, add 120L of water, stir and mix well, heat to 55°C, add 37g (20U / g) of 2709 alkaline protease, and perform enzymatic hydrolysis for 7 hours, with the reaction temperature controlled at 50-55°C Centrifugal separation after the enzymolysis reaction, the precipitate was washed twice with 45L water, and air-dried to obtain 7.5kg of rice starch, so that the water content was below 12%. The supernatant was concentrated to 20%-25% solids. Then the concentrated feed liquid is spray-dried to obtain 1 kg of rice protein product, so that the moisture content is below 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com