Turbine cylinder casing thermal insulating method and thermal insulating cabin

A cylinder casing and steam turbine technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as high cost of use, waste of the environment, and large waste, and achieve the effects of simple structure, good heat preservation effect, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

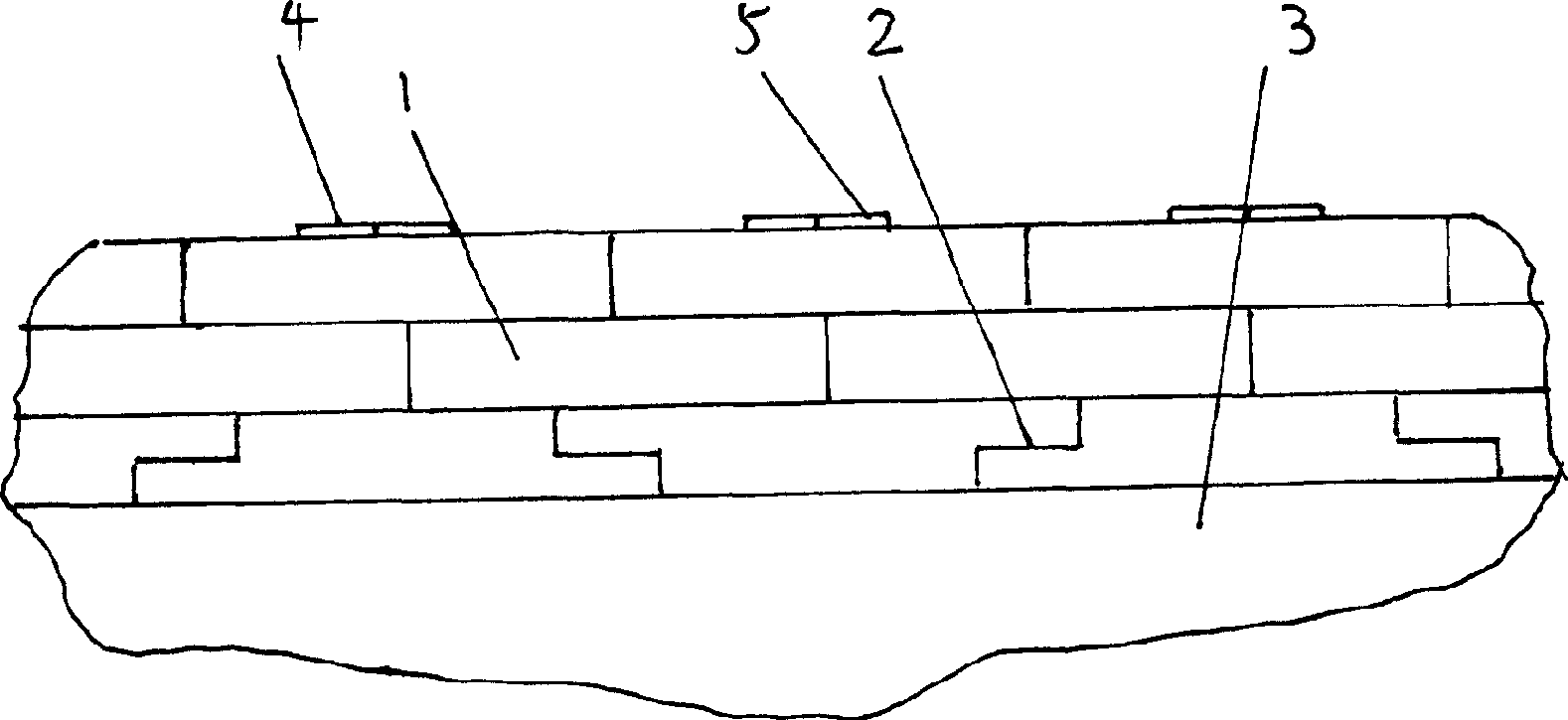

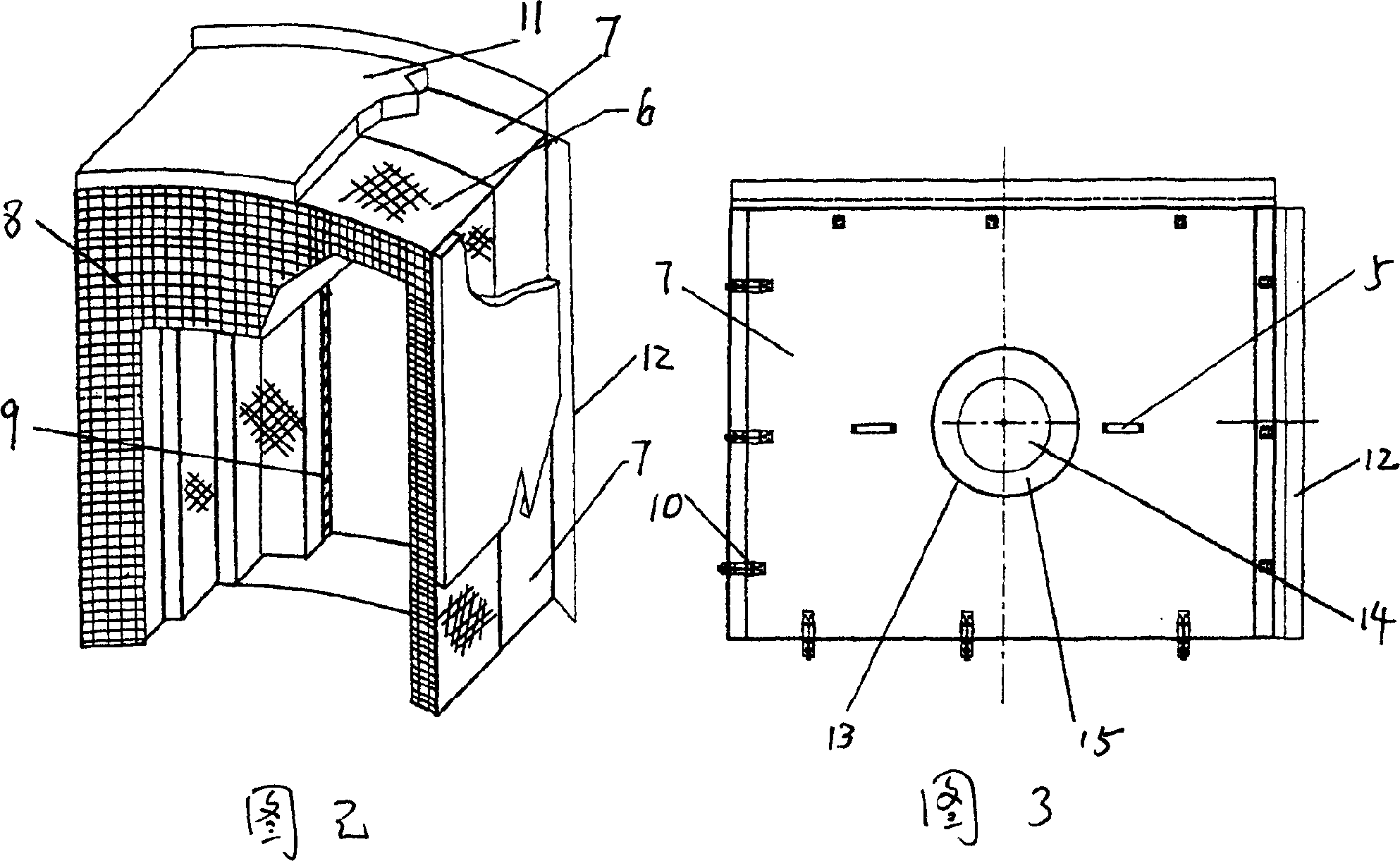

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings: the thermal insulation method of the present invention, it is to make a certain number of block thermal insulation blankets first according to the surface shape and size of the cylinder shell, and lay a piece of thermal insulation blanket on the steam turbine shell. At least two thermal insulation layers are formed on the surface.

[0019] The formation of the thermal insulation layer is as follows: first laying a thermal insulation layer spliced by a block-shaped thermal insulation blanket on the surface of the steam turbine casing, and then splicing a layer of thermal insulation layer composed of the same or different block thermal insulation blankets on it, And when the upper insulation layer is spliced, the upper insulation blanket covers the connection gap formed between the two insulation blankets in the lower insulation layer, and the upper and lower layers for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com