Drawing frame of a staple fibre spinning machine comprising a central fibre guide

A technology of man-made staple fibers and guiding devices, which is applied in spinning machines, textiles, papermaking, and drafting equipment, etc. It can solve the problems of yarn hairiness degradation and increase yarn hairiness, so as to save space and ensure stable alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

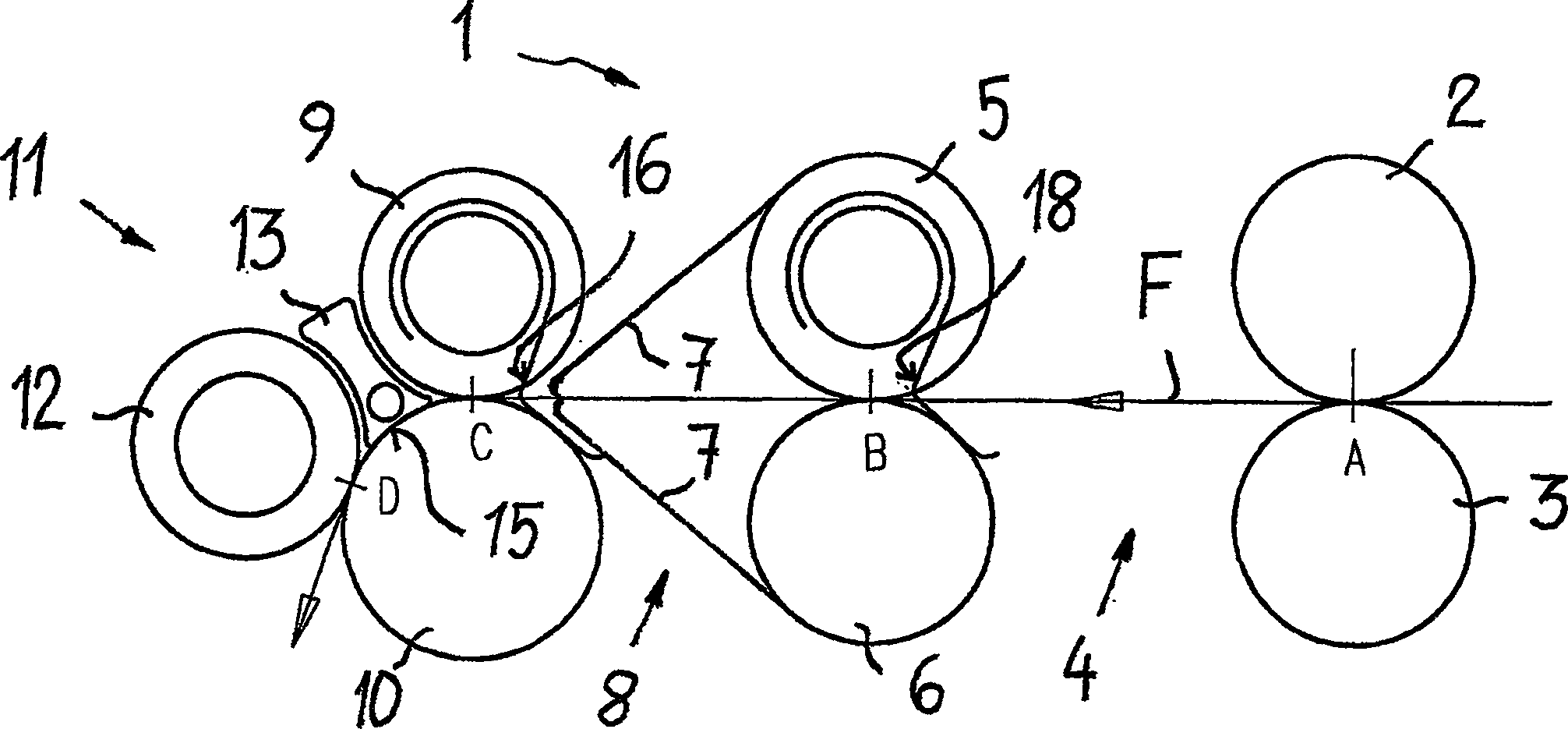

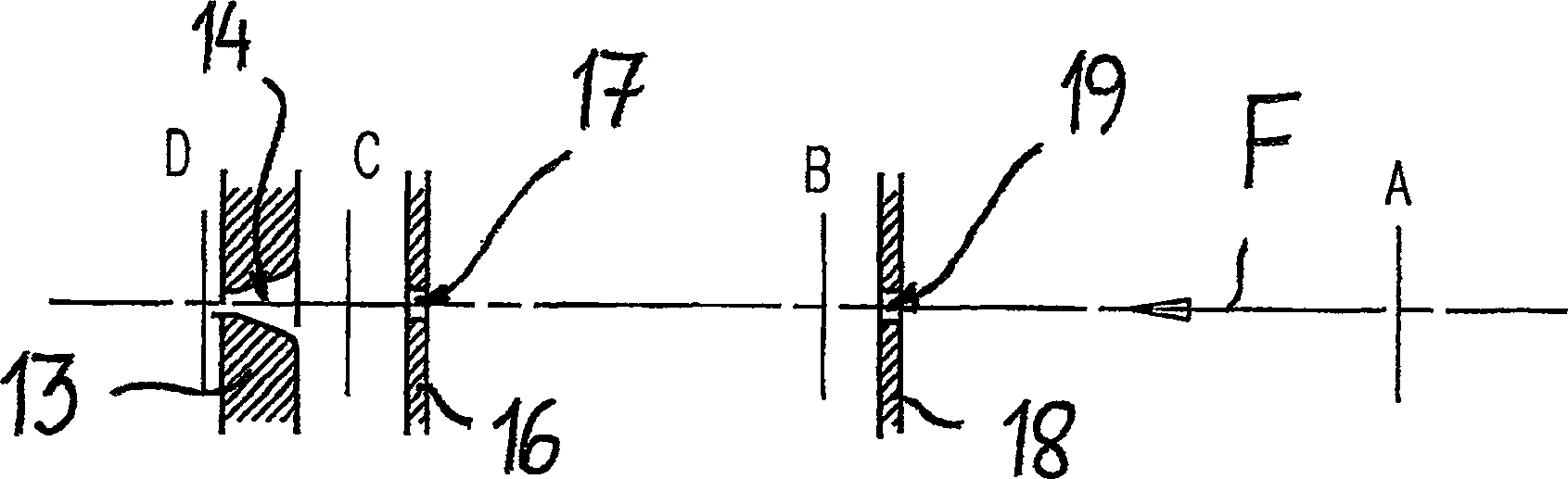

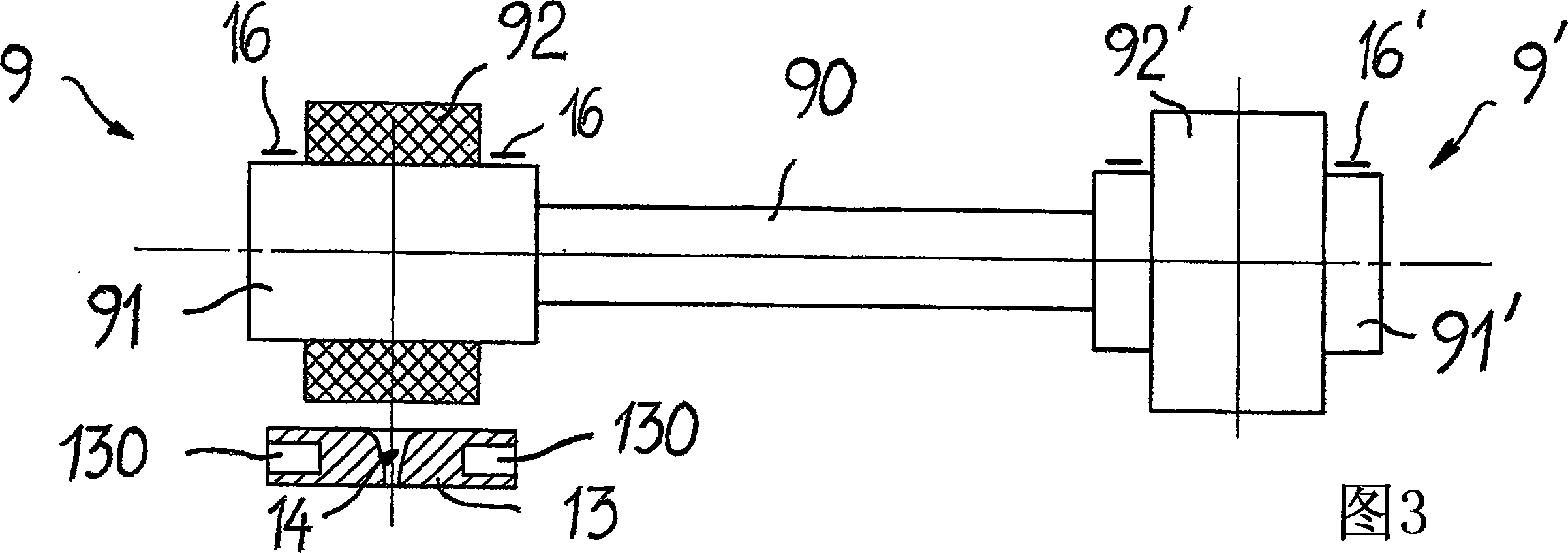

[0022] [22] The terms "back" or "front" used below always refer to the direction of feed of the sliver through the draw frame of the staple fiber spinning machine. figure 1 and figure 2 A drawing frame embodied according to the invention is shown schematically, which is designated as a whole by the reference number 1 . The draw frame 1 is a so-called three-roll draw frame with a pre-drafting zone 4 and a main drafting zone 8 for the sliver F. The feed direction of the sliver F is indicated by arrows. The pre-drafting zone 4 extends from the entry pressure roller 2 and the entry bottom roller 3 to the middle pair of rollers, which is formed by the apron roller 5 and the associated middle bottom roller 6 . The double apron 7 of the main drafting zone 8 runs through this apron roller 5 . The main drafting zone 8 extends from the central pair of rollers 5 , 6 to the delivery press roll 9 supported on the lower roll 10 . The entry nip line A is defined by the contact area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com