Sewing machine

A sewing machine and thread adjusting device technology, applied in sewing machine components, sewing equipment, program-controlled sewing machines, etc., can solve the problems of inability to form zigzag parallel parts, unevenness, and disordered stitches, and achieve smooth and stable tension changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below, combine Figure 1 to Figure 8 , the embodiment of the present invention will be described.

[0065] The sewing machine 100 of the present embodiment is an example of a buttonhole sewing machine in which the present invention is applied to form buttonhole stitches for buttonholes on a sewn object.

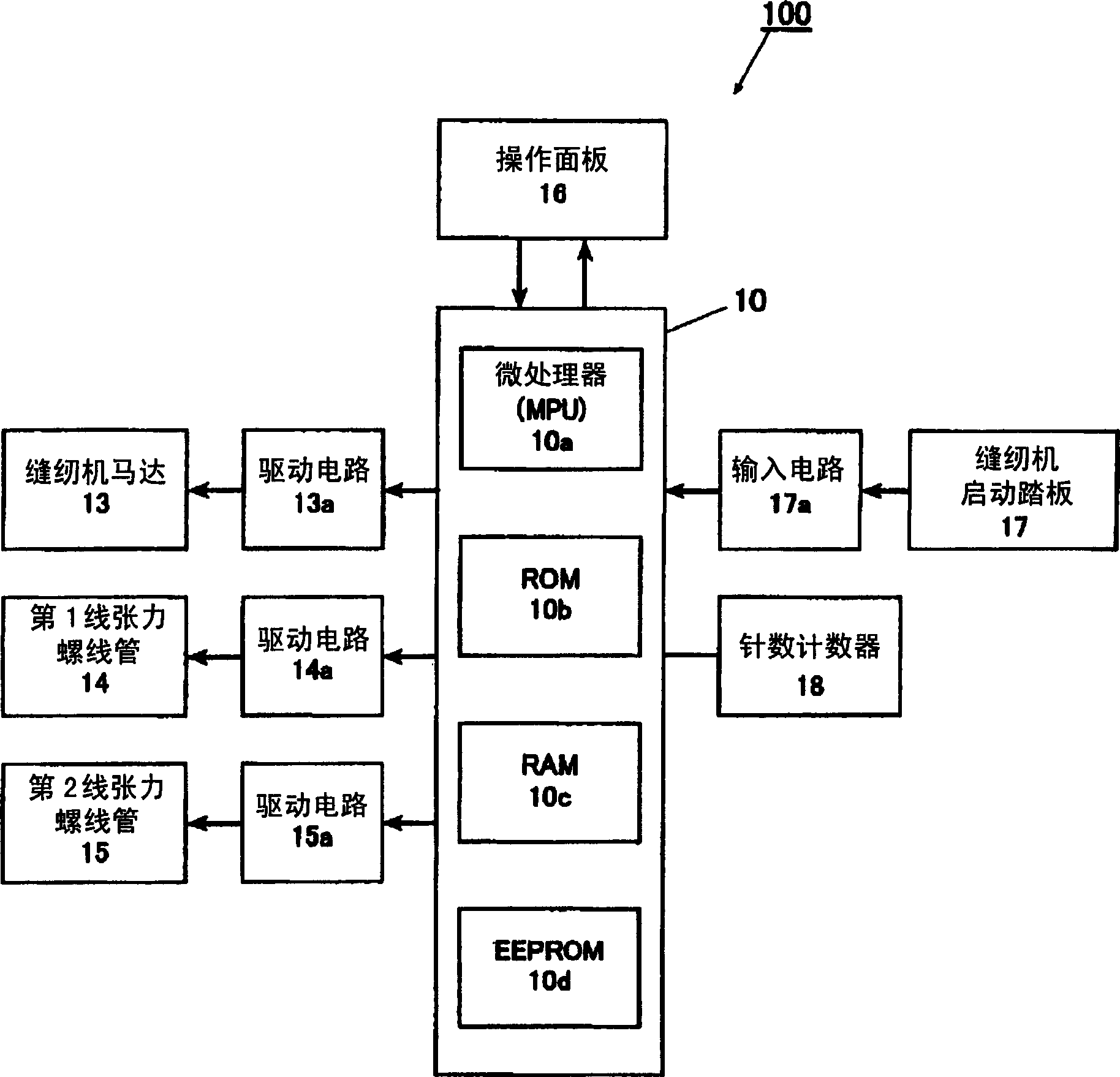

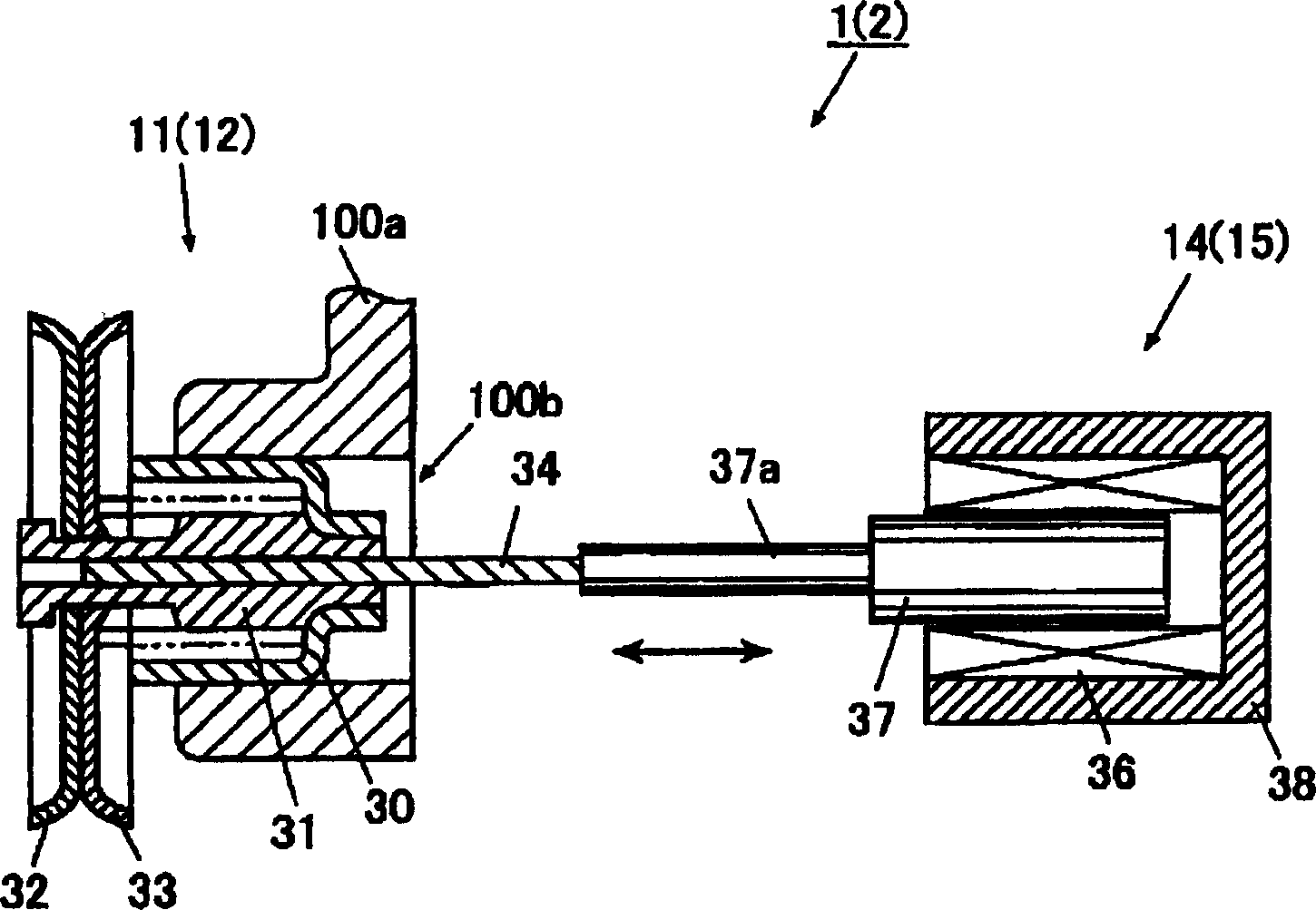

[0066] Such as figure 1 , figure 2 As shown, the sewing machine 100 has: a sewing machine motor 13 as a sewing machine drive source, a sewing machine start pedal 17 that drives the sewing machine motor 13 to rotate, a needle bar 130 that moves up and down as the sewing machine motor 13 is driven by rotation, and is fixed on Machine needle 131 on needle bar 130. In addition, the sewing machine 100 has a first thread adjusting device 1, a second thread adjusting device 2, a take-up thread arrangement, and a first thread adjusting device 1, a second thread adjusting device 2, and a thread adjusting device 1 arranged on the upper thread path R along which the upper th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com