Auto air duct plate open-type foaming device and its air duct plate production method

A foaming device and open-plate technology, which is applied in the field of open-type foaming devices for automobile air duct panels, can solve problems affecting the quality of air duct panels, low production efficiency, and inability to form molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

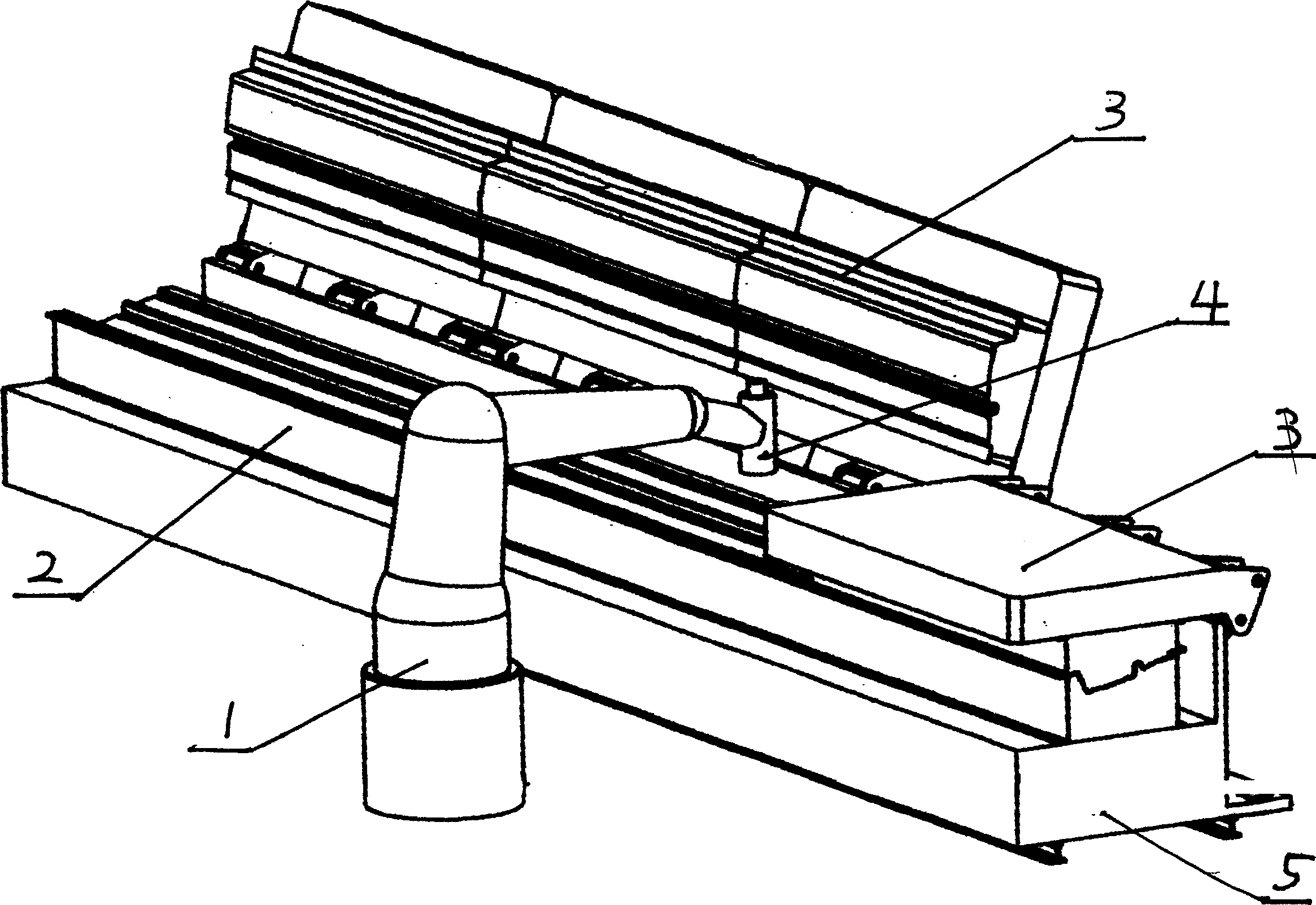

[0009] refer to figure 1 , the automobile air duct plate open foaming device, including a foaming unit 1, a forming die, a mold platform 5, the forming die is installed on the die platform 5, the forming die is divided into a bottom mold 2, a cover mold 3, the bottom The mold 2 is a whole, and the cover mold 3 is divided into a multi-section cover mold 3 relative to the bottom mold 2 (the number of the 3 sections of the cover mold is more than 2), and the multi-section cover mold 3 is equivalent to the bottom mold 2 when all of them are closed. The length of the mold platform 5 is controlled by power and can move forward and backward, so that the polyurethane fiberglass mixture nozzle 4 of the foaming unit 1 can continuously pour the polyurethane fiberglass mixture on the bottom mold 2 during the left and right movement, so that the bottom mold 2 can continuously Pouring the polyurethane fiberglass mixture and closing the cover mold 3 section by section to ensure that the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com