Pipe line-closing device

A sealing device and pipeline technology, applied in the directions of water supply devices, pipe components, water supply main pipes, etc., can solve the problem of losing the locking function of the locking link, and achieve simplicity, relaxation, noise reduction, and impact. The effect of softening and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

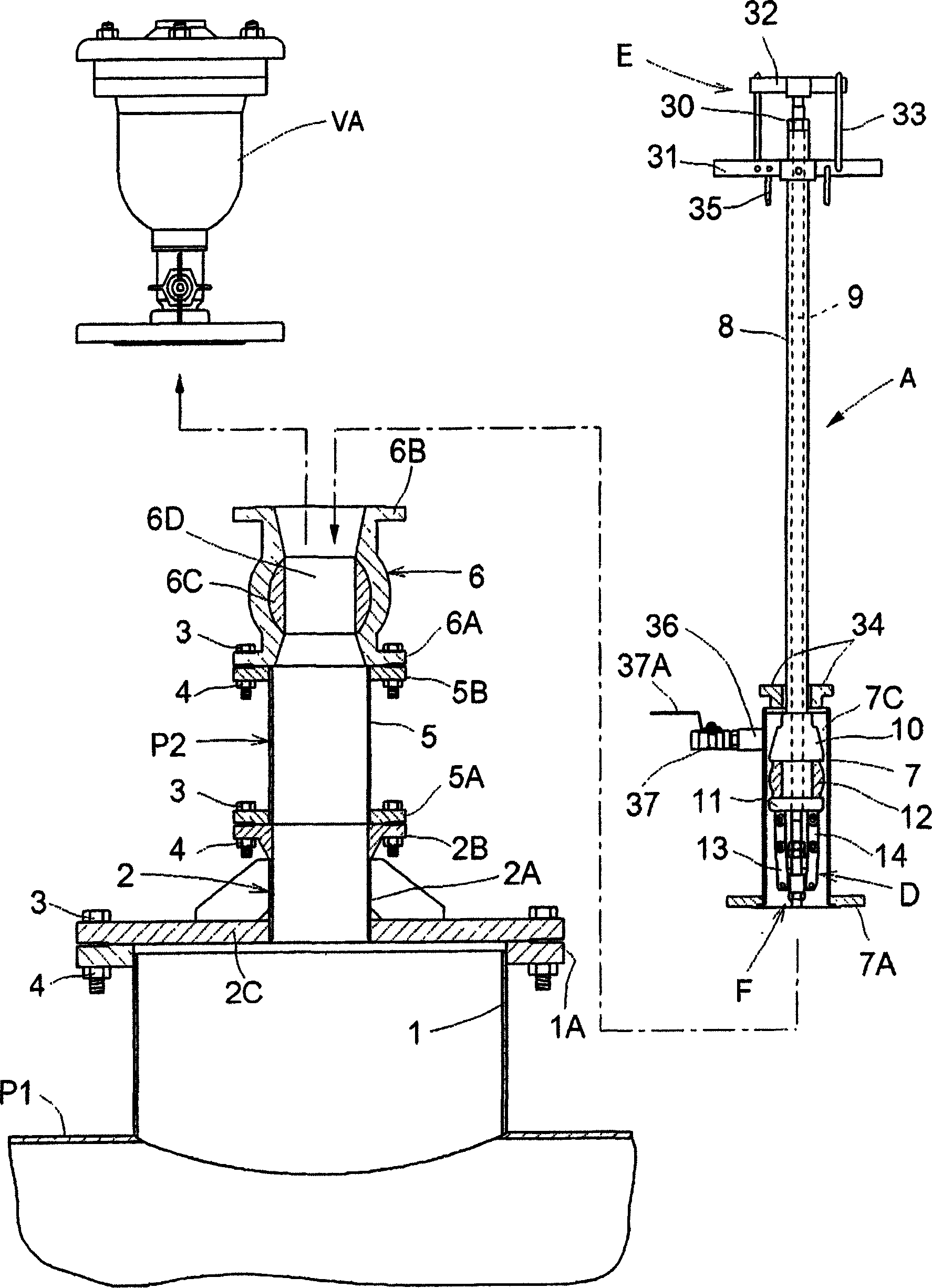

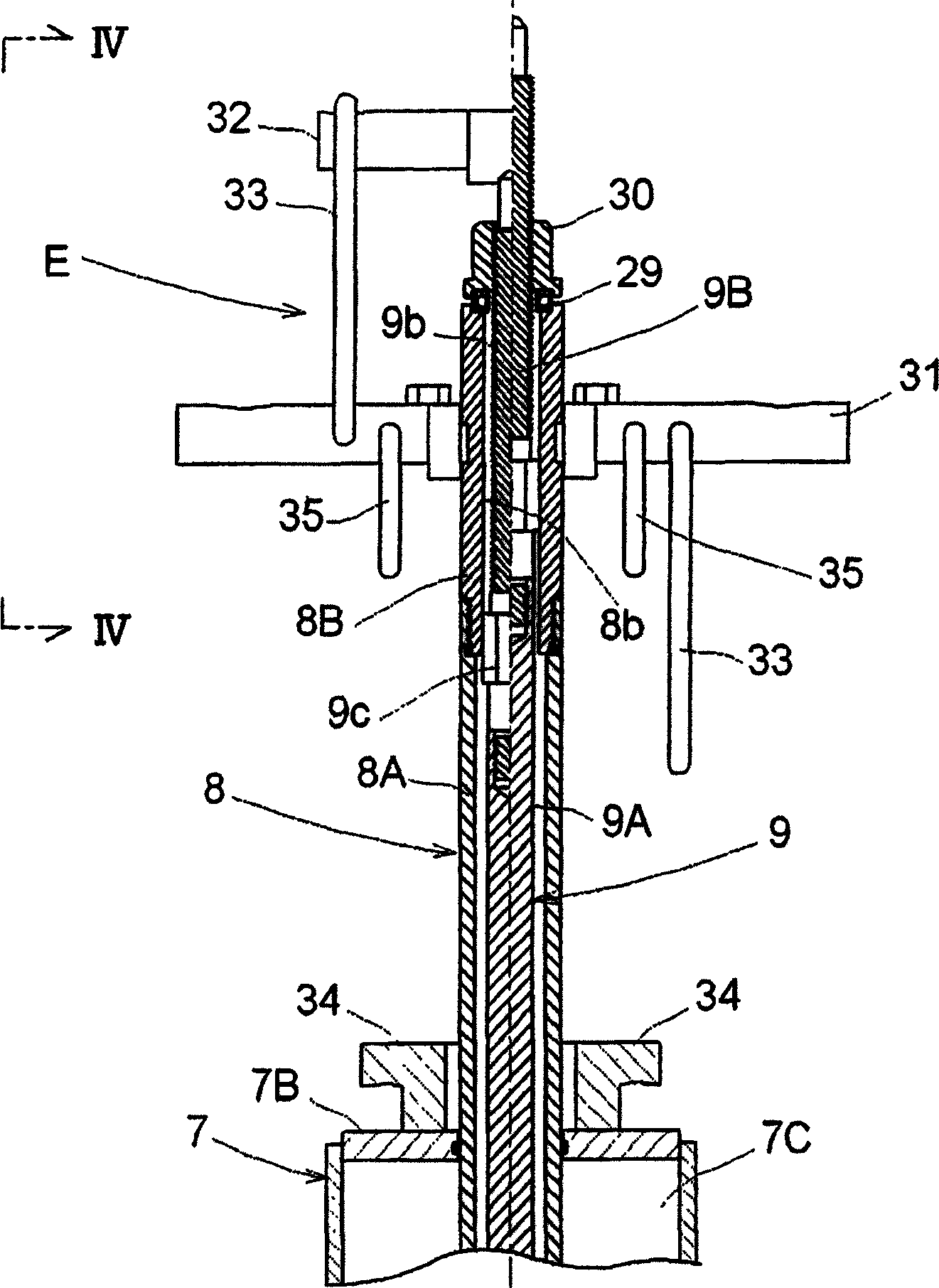

[0059] The following description will be made with reference to the accompanying drawings of the pipeline sealing device A used in the case where the flow of water from the branch pipe can be prevented even if the water supply in the water main pipe P1 is performed, and the valve replacement method using the pipeline sealing device A. In the state of P2 leaking, replace the gate valve 6 clamped in the branch pipe P2 with a new gate valve 6 .

[0060] figure 1 Represents a branch connection configuration midway in a fluid delivery path. In this branch pipe connection structure, a connection cover having a connection pipe portion 2A having a diameter smaller than its inner diameter is detachably fixed and detachably connected to the connection flange portion 1A of the branch pipe portion 1 via bolts 3 and nuts 4 in a sealed state. body 2, the branch pipe portion 1 is integrally protrudingly formed in the middle of a water main pipe P1 as an example of a main pipe for fluid tra...

no. 2 Embodiment approach

[0092] In the above-mentioned first embodiment, it is configured that the first pressing plate 10 is moved close to the second pressing plate 11 by artificially tightening the screw member 30, but it may also be as follows: Figure 13 As shown, it is configured such that the first pressing plate 10 is moved close to the second pressing plate 11 by a pair of hydraulic jacks 40 .

[0093] That is, on the operation extension cylinder shaft 8B of the first operation shaft 8, a pair of first push operation levers 31 are detachably fitted and held, and a hydraulic pressure lever 31 is attached to each first push operation lever 31 through a bolt 42. The mounting plate 41 of the jack 40. Furthermore, a substantially T-shaped operating arm 43 having a pressure receiving surface 43a that can abut against the end of the piston rod 40A of the hydraulic jack 40 is detachably screwed to the operation extension shaft 9B of the second operating shaft 9 .

[0094] In addition, other structur...

no. 3 Embodiment approach

[0096] Figure 14Shows an improvement of the anti-turnover mechanism F, which abuts against the pair of locking links 13 and 14 of the anti-loosening mechanism D to restrict them when the pair of locking links 13 and 14 are extended and operated to reduce their diameters. In the following predetermined outer bending posture, the bent pivot support portion S2 of the locking link pair 13 , 14 protrudes outward in the radial direction. On the downstream side end of the metal mounting cylinder 21, a straightening flange portion 25 is integrally formed. Abutting each upstream locking link 13 is held in the outer bending posture closest to the set limit of the line segment Y. In addition, an elastic correction ring 45 made of elastically deformable urethane rubber or the like is externally installed between the correction flange portion 25 and the second connecting portion 22, and the elastic correction ring 45 moves toward a diameter-shrinking posture as the locking link faces. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com