Improving method of mucilage extraction

A technology of latex and rubber tapping, applied in forestry, application, agriculture, etc., can solve the problems of gaseous stimulants wasting production, bark bursting, rubber tree damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

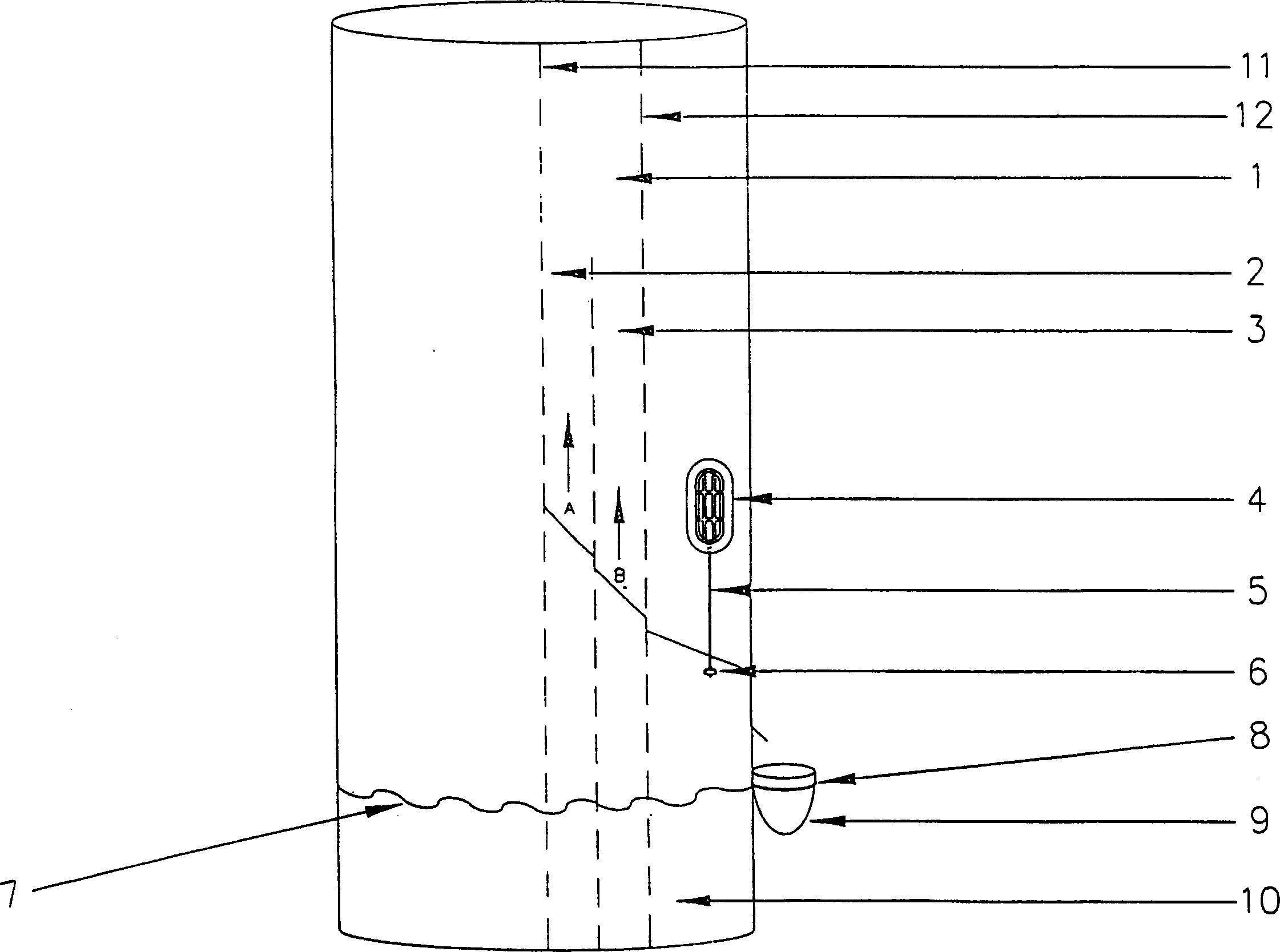

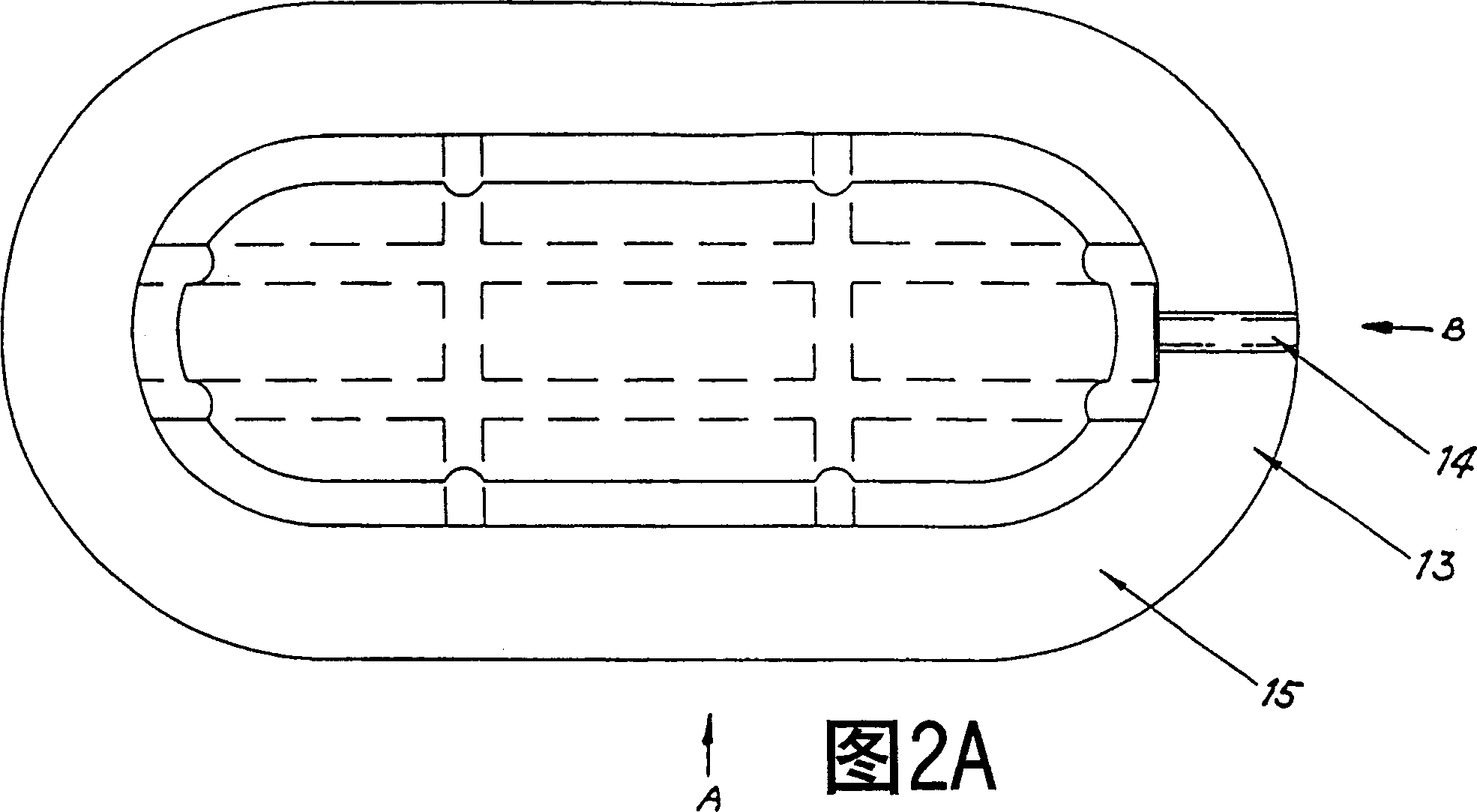

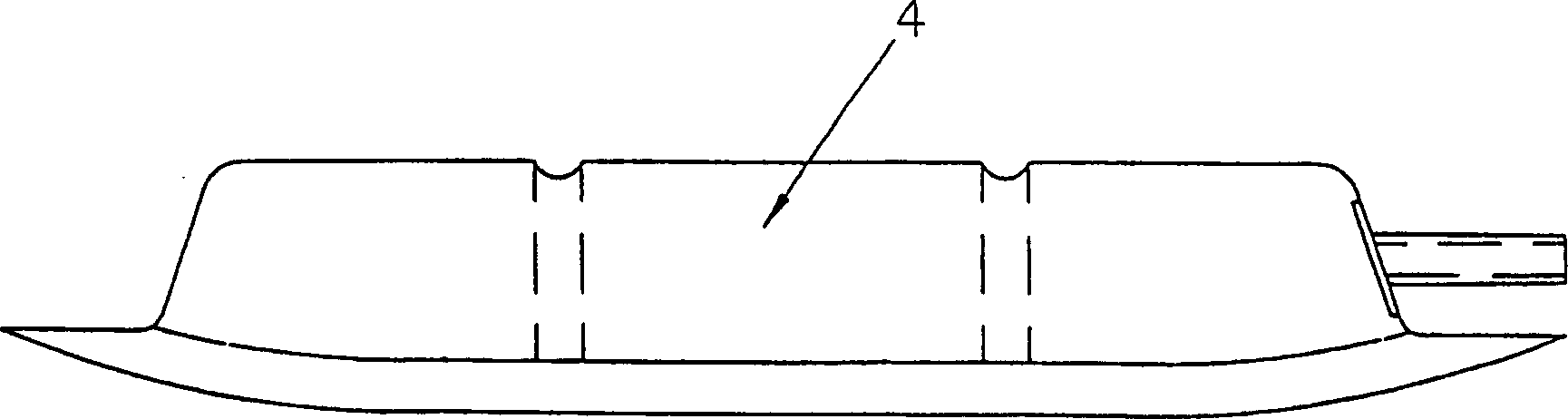

Method used

Image

Examples

example 1

[0027] The previous method for securing prior art applicators to the bark of a rubber tree was compared to the use of an instant fix applicator that was pre-applied with a specially formulated butyl rubber adhesive sealant along the flange at the factory ( IFA) installation speed and labor consumption were compared.

[0028] Time and action studies conducted on a wide scale have shown that if a worker employs archaic techniques to apply water-reactive glue to the applicator, pin the applicator to the bark, secure the PVC pipe and valve and coat as an external seal contact adhesive, the worker can only complete the above sequence on 100 trees per 8-hour workday.

[0029] In contrast, by using an instant fix applicator (IFA), which involves removing the silicon paper from the pre-coated applicator in situ, stapling the applicator to the bark, applying the sealant to the flange area Physical pressure, pipes and valves to secure the applicator, workers can do this on 250 trees pe...

example 2

[0031] Combine the newly improved dual 1 / 8s incision tapping surface change system (2 x 1 / 8s d / 1 2d / 3 + gas stimulation applicator) combined with gas stimulation 2 with a single incision 1 / 8s over a period of 60 days Tapping frequency of d / 2 d / 3 plus gas stimulation on the HO-1 tapping surface of the RRIM600 clone tree was used for comparison. Through the new and improved tapping system, the average yield per tree per month is 1.87kg, which is 82% higher than the yield obtained by tapping rubber trees with a traditional single 1 / 8s incision. Assuming a rubber forest with 300 trees per hectare, the projected yield per hectare with the new and improved system would be 5610kg per hectare per year.

[0032] It will be appreciated that the present invention provides a rubber tapping system for use with gaseous ethylene stimulation, which enables up to 20 rubber tappings per month, a frequency unattainable with the tapping frequencies employed so far in the prior art. The system al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com