Device and method for implementing patterns on the narrow side of the plate workpieces

A plate-shaped workpiece, narrow technology, applied in the direction of printing devices, manufacturing tools, wood processing equipment, etc., can solve the problems of high work cost and standby time, and achieve the effects of minimizing misprinting, improving pattern quality, and saving printing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

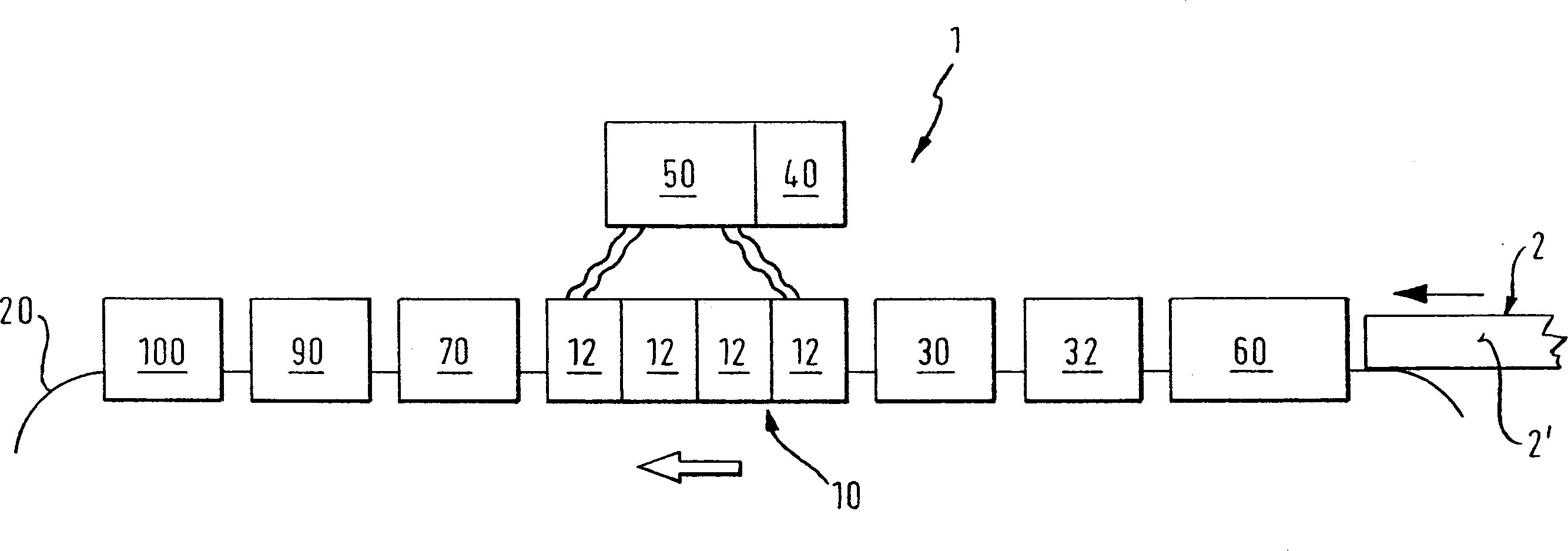

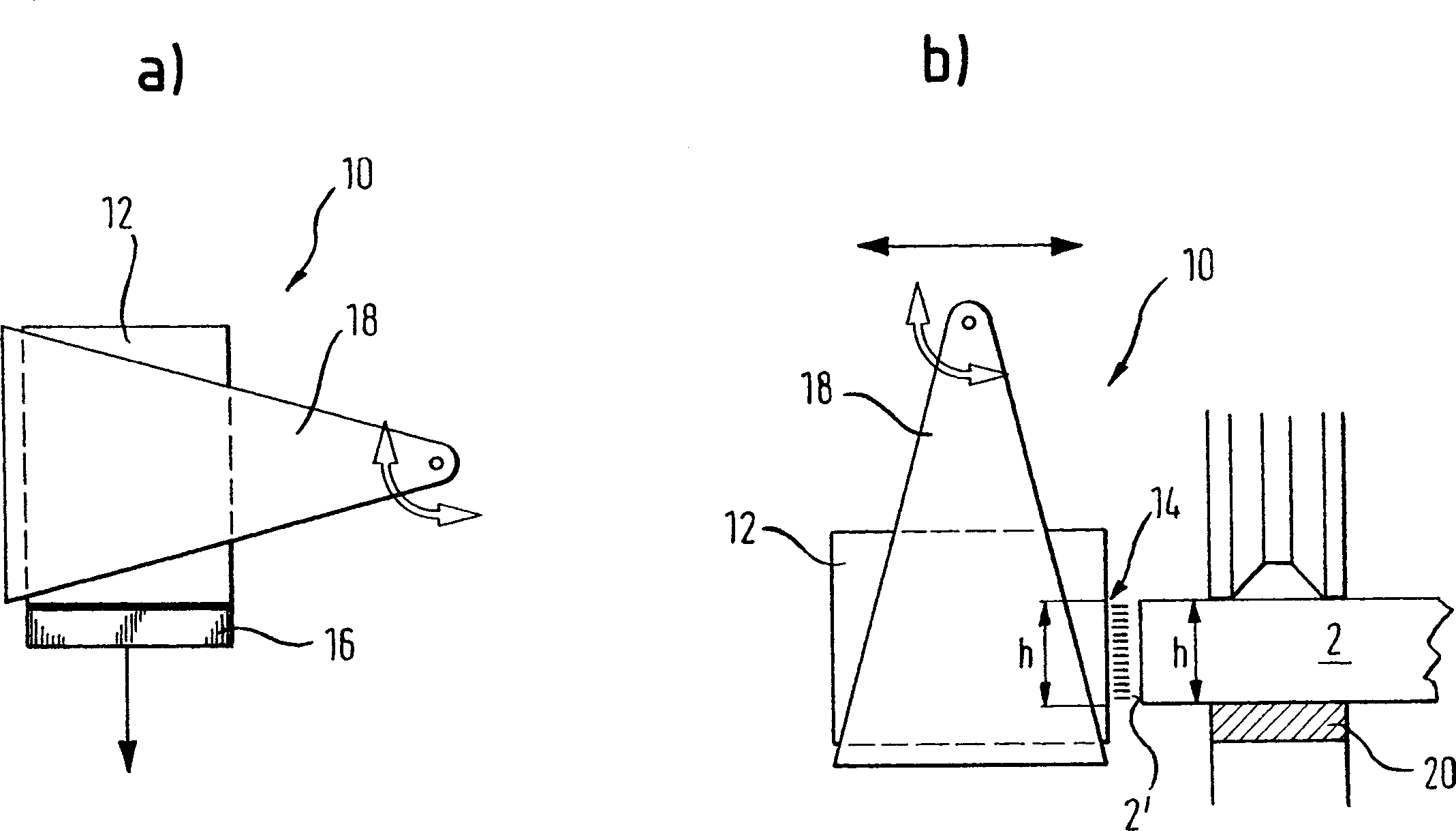

[0025] figure 1 A side view of a first embodiment of the device according to the invention is schematically shown. The shown device 1 is used for printing a pattern on the narrow side 2' of a plate-shaped workpiece 2, which is preferably substantially made of wood or wood and is embodied, for example, as a furniture part, a kitchen worktop or the like. It should be noted that the present invention is not limited to printing patterns on narrow sides, and in principle, the present invention is also suitable for printing patterns on wide surfaces of plate-shaped workpieces.

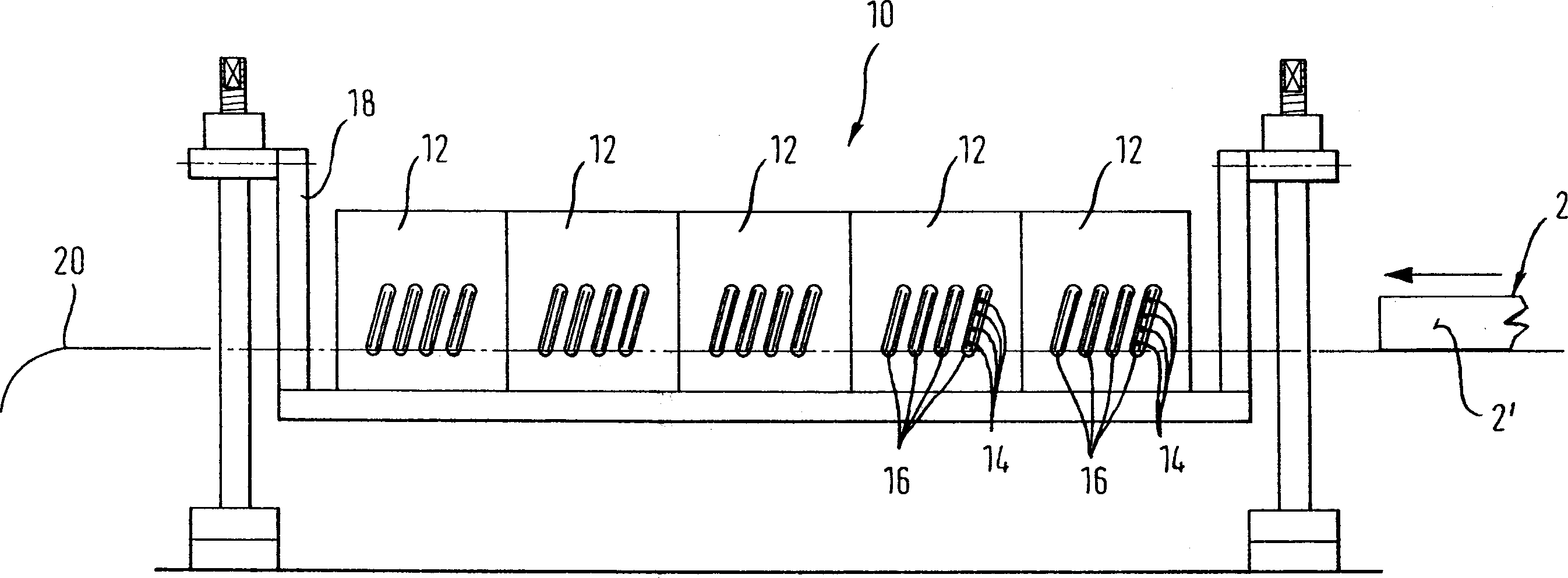

[0026] The device 1 comprises a stationary printing unit 10 which, in the present embodiment, has four inkjet print heads 12 . One printhead ejects black, one printhead magenta, one printhead yellow, and one printhead cyan, which makes sense for multi-color patterns. Eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com