Method and machine for non-destructive stretching and fastening of a pelt on a pelt board

A stretching equipment, non-destructive technology, applied in leather stretching/stretching, fur trimming, leather drying, etc., can solve the problem that the stretching machine can no longer be used, and achieve the effect of price reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

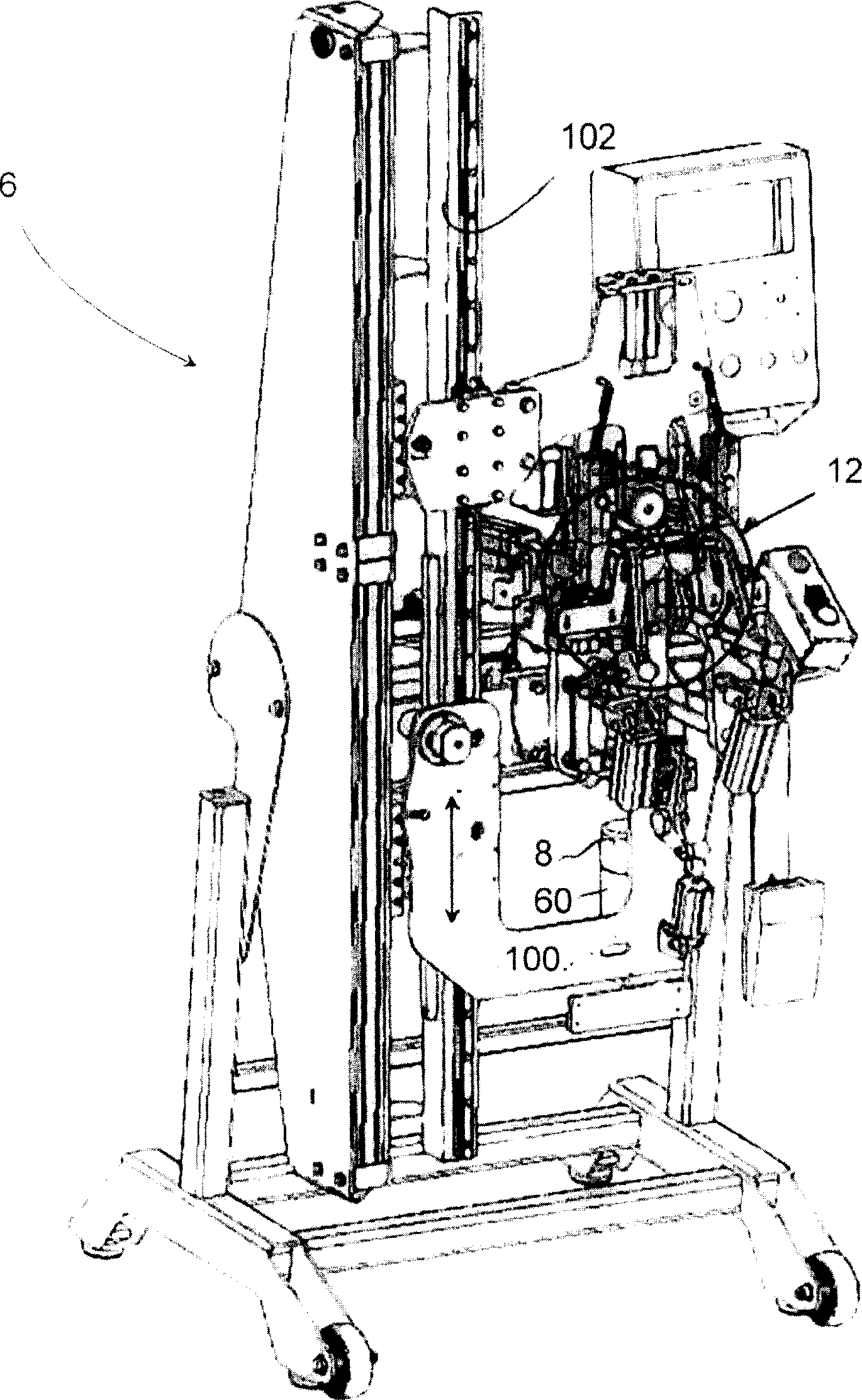

[0055] figure 1A perspective view of a stretching device 6 carrying out the method according to the invention is shown in . The stretching device 6 comprises holding means 8 for engaging / fixing the lower end 24 of the fur panel 4 (not shown), which in the illustrated embodiment of the device 6 rests on a U-shaped bracket plate 100, The carriage plate is accommodated in the guide rail 102 in a movable manner. The movement of the carriage plate 100 and thus the holding device 8 in the direction of the rails can be effected by means of an actuator, not shown, typically comprising a pneumatic piston (not shown). The device 6 comprises a clamping part 12 arranged at a certain height above the holding device 8 , the position of which is confined within the circle indicated by reference numeral 12 .

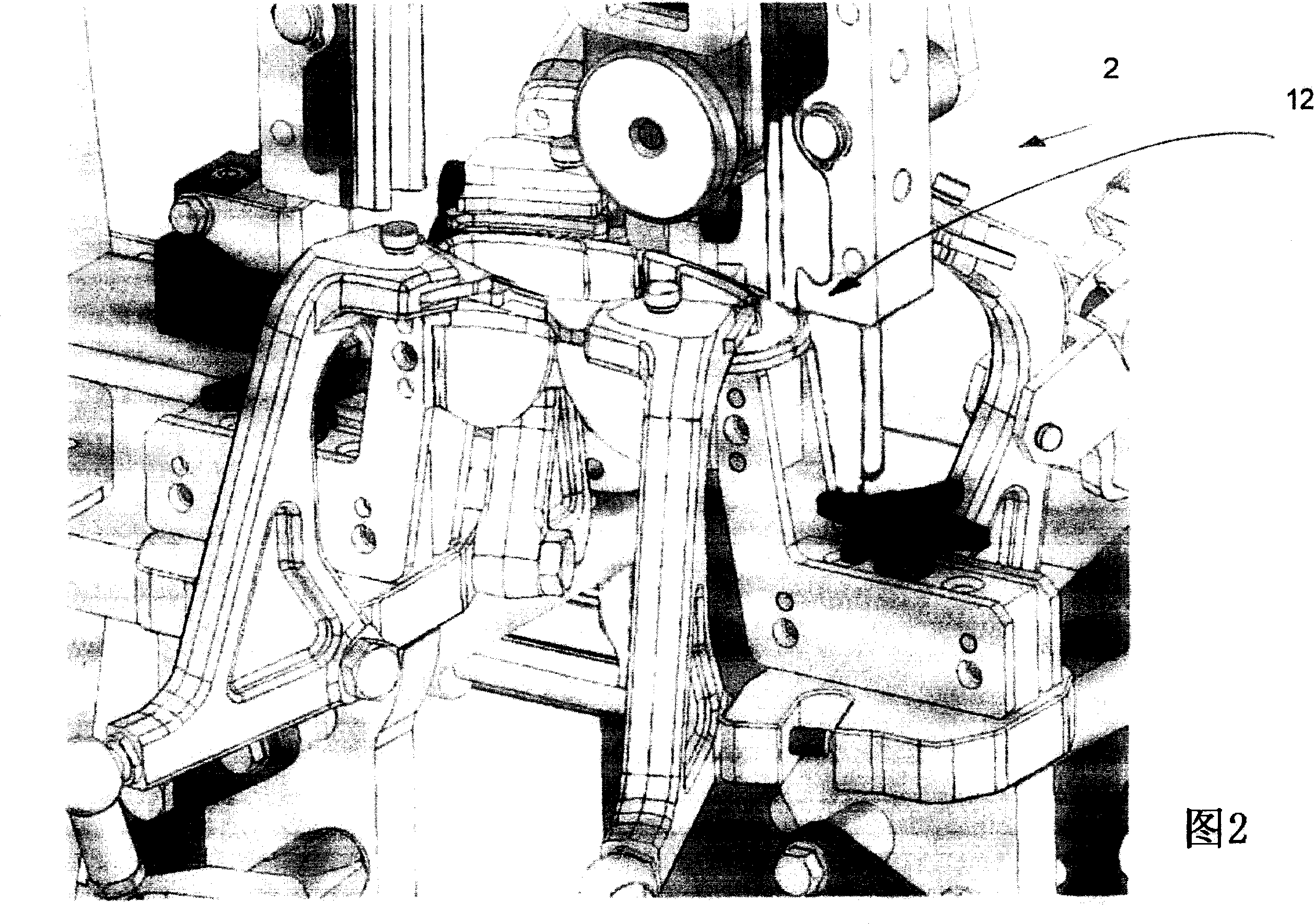

[0056] Figure 2 is figure 1 A perspective view of a detail of the device shown, showing the clamping part 12 .

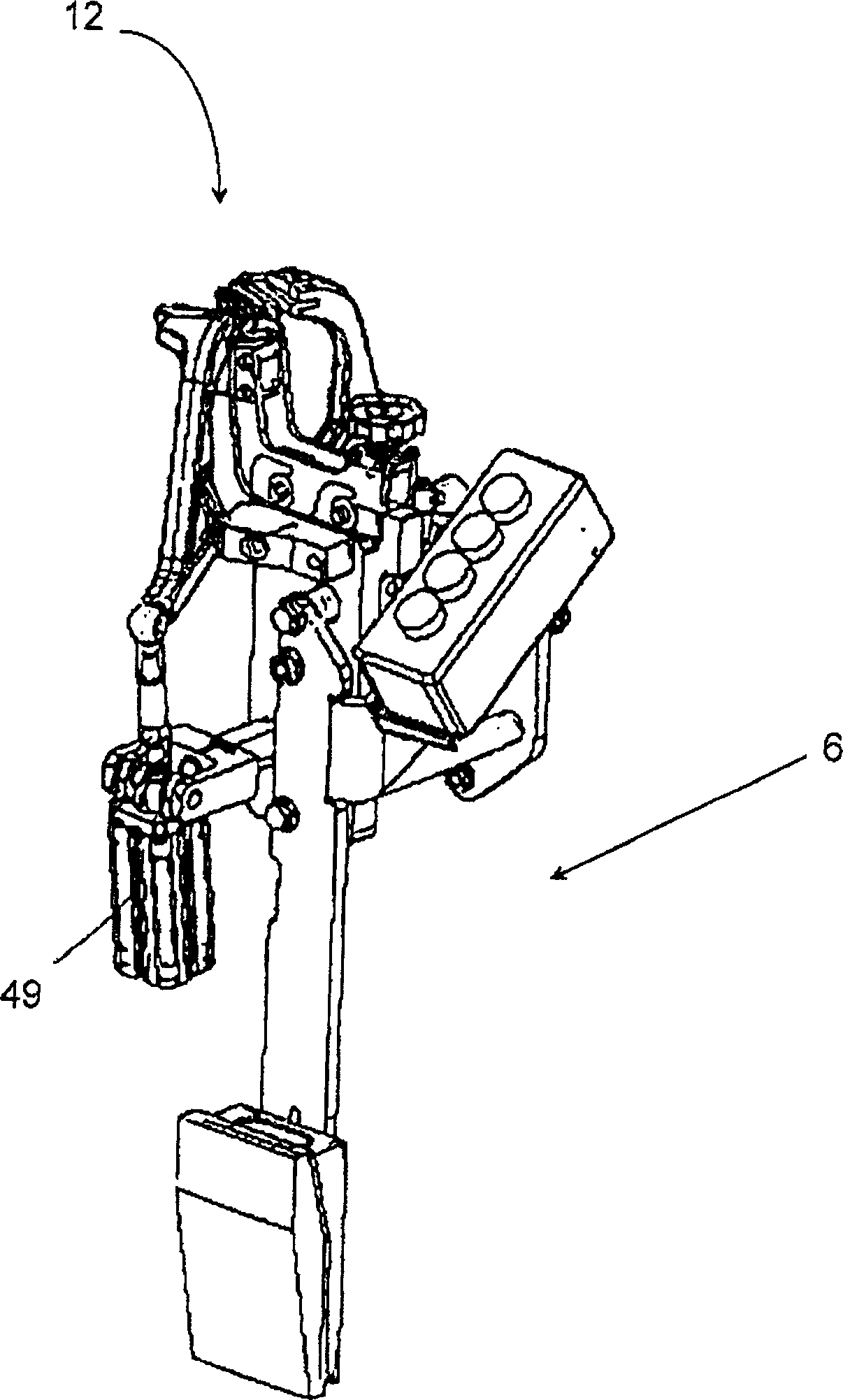

[0057] image 3 It is a perspective view of half of the clamping pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com