Two-for-one twisting mechanism

A technology of frame and yarn guide device, applied in textiles and papermaking, etc., can solve the problems of hairiness, poor yarn strength, yarn breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

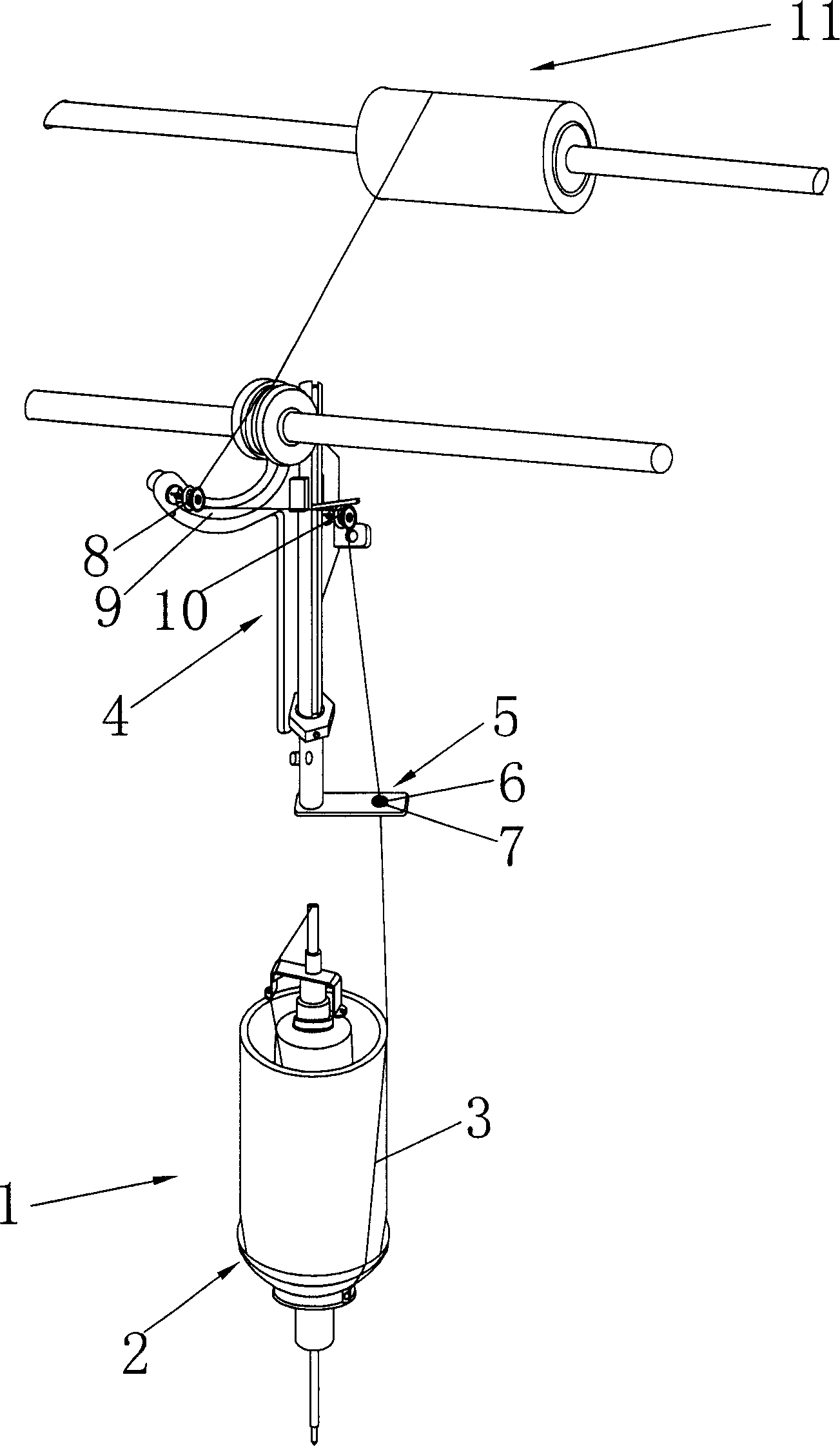

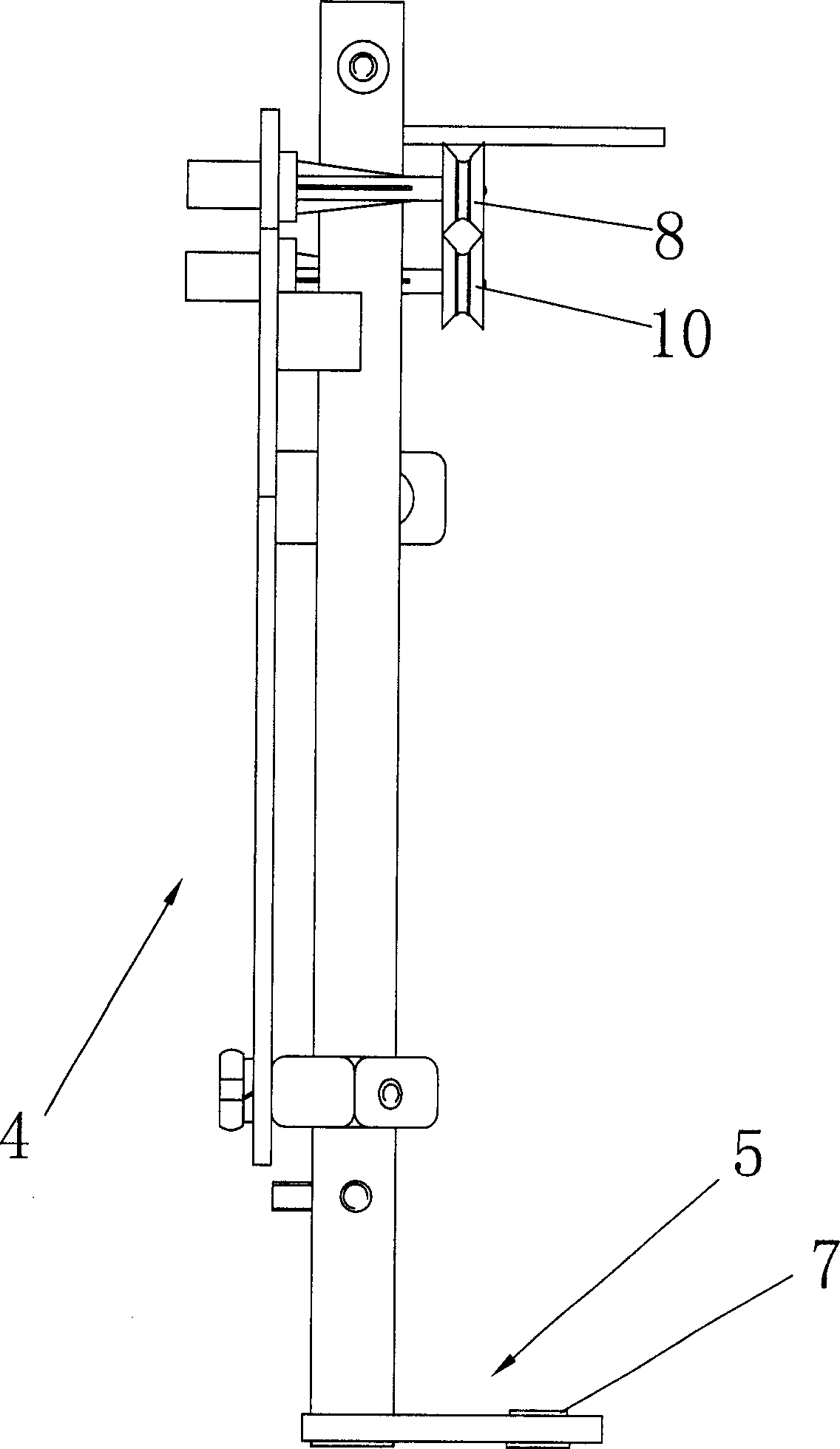

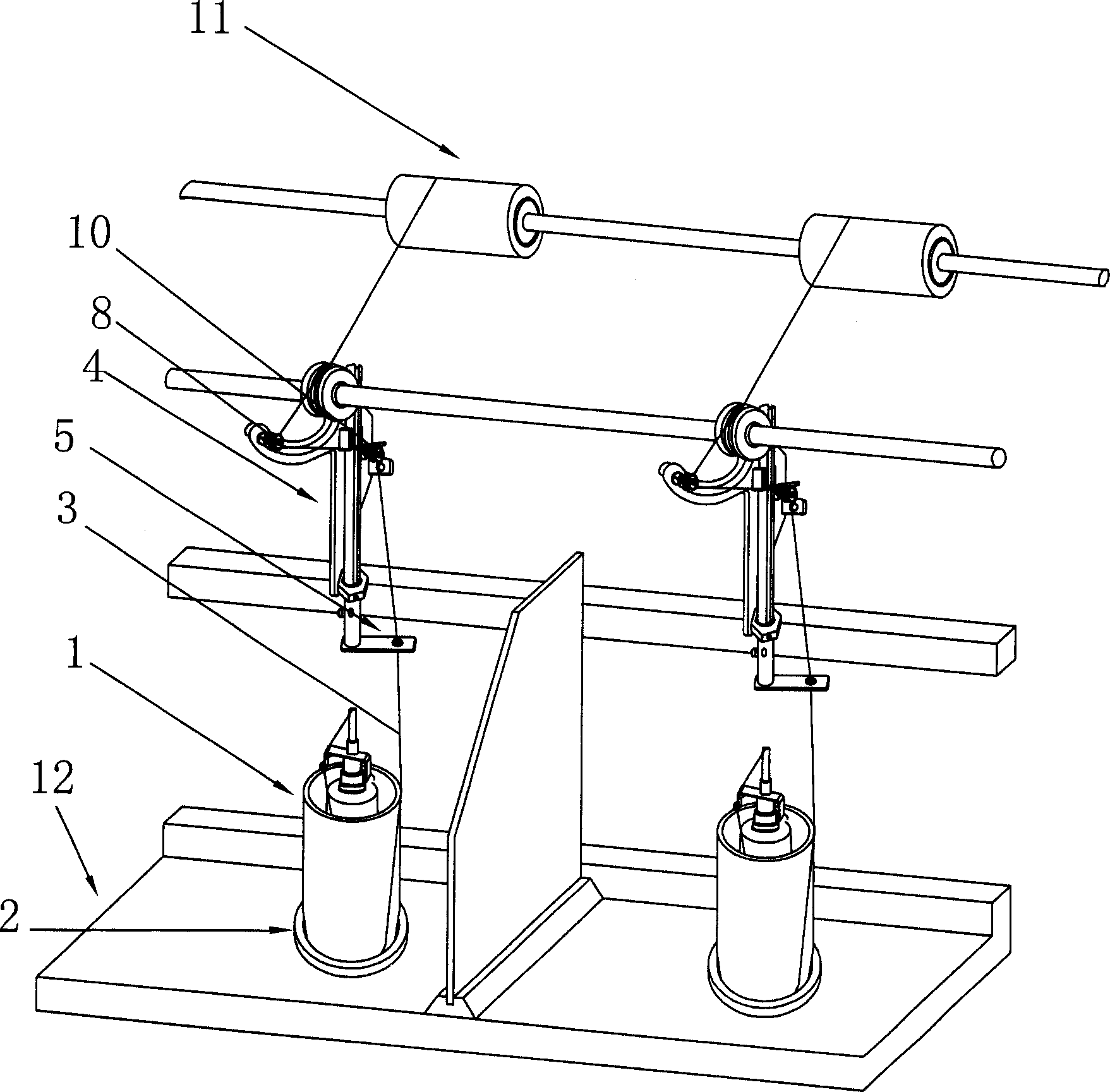

[0013] See attached figure 1 - attached Figure 4 As shown, a two-for-one twisting mechanism includes a frame 12, a spindle turntable 2 rotatably arranged on the frame 12, a yarn storage drum 1 arranged on the spindle turntable 2, and a The yarn guiding device and the winding device 11 on the frame 12, the described yarn guiding device is located between the yarn storage drum 1 and the winding device 11, and the described yarn guiding device comprises a yarn guiding bracket 4, which is arranged on the The yarn threading plate 5 on the yarn guide bracket 4, the threading plate 5 is provided with a bearing 7, the bearing 7 includes a relatively rotatable inner ring 14 and an outer ring 13, and the yarn 3 passes through the inner ring 14, And the outer ring 13 is fixed on the said yarn threading plate 5 . In the embodiments shown in the drawings, the yarn threading plate 5 is provided with a mounting hole 6, and the bearing 7 is arranged in the mounting hole 6.

[0014] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com