Short arm-tie type grab bucket

A rod-type, grabbing bucket technology, which is applied in the field of lifting machinery grabbing devices, can solve the problems of weakened closing force of the jaw plate of the grabbing bucket body, small grabbing force and digging force, large grabbing force and digging force, etc. Achieve the effect of strong gripping ability, long service life and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

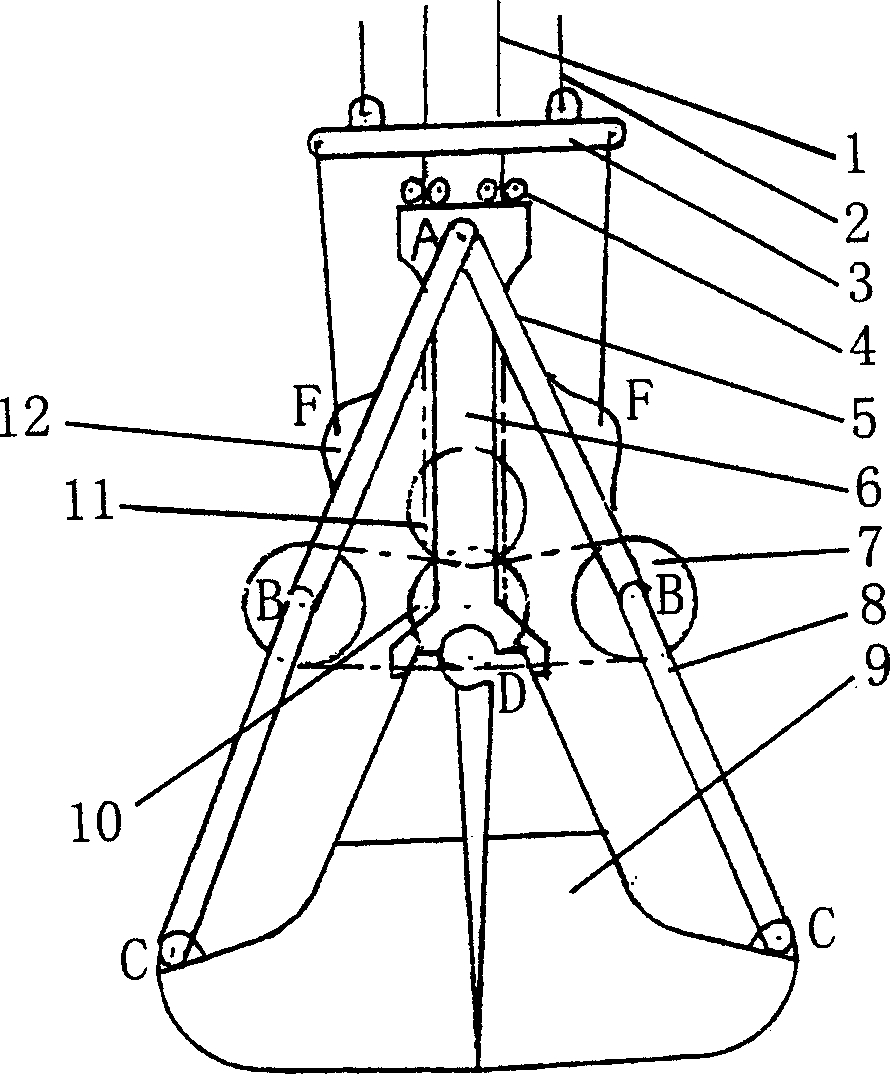

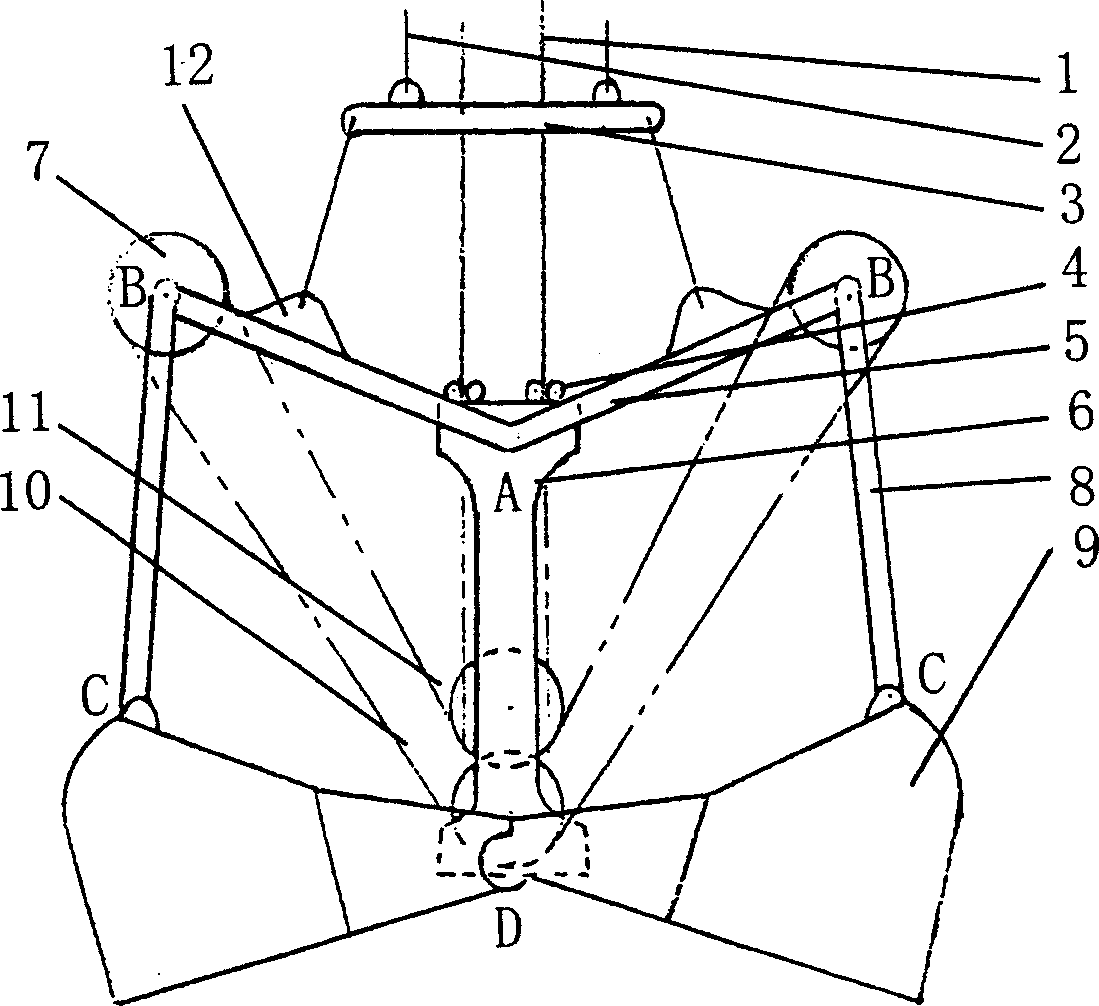

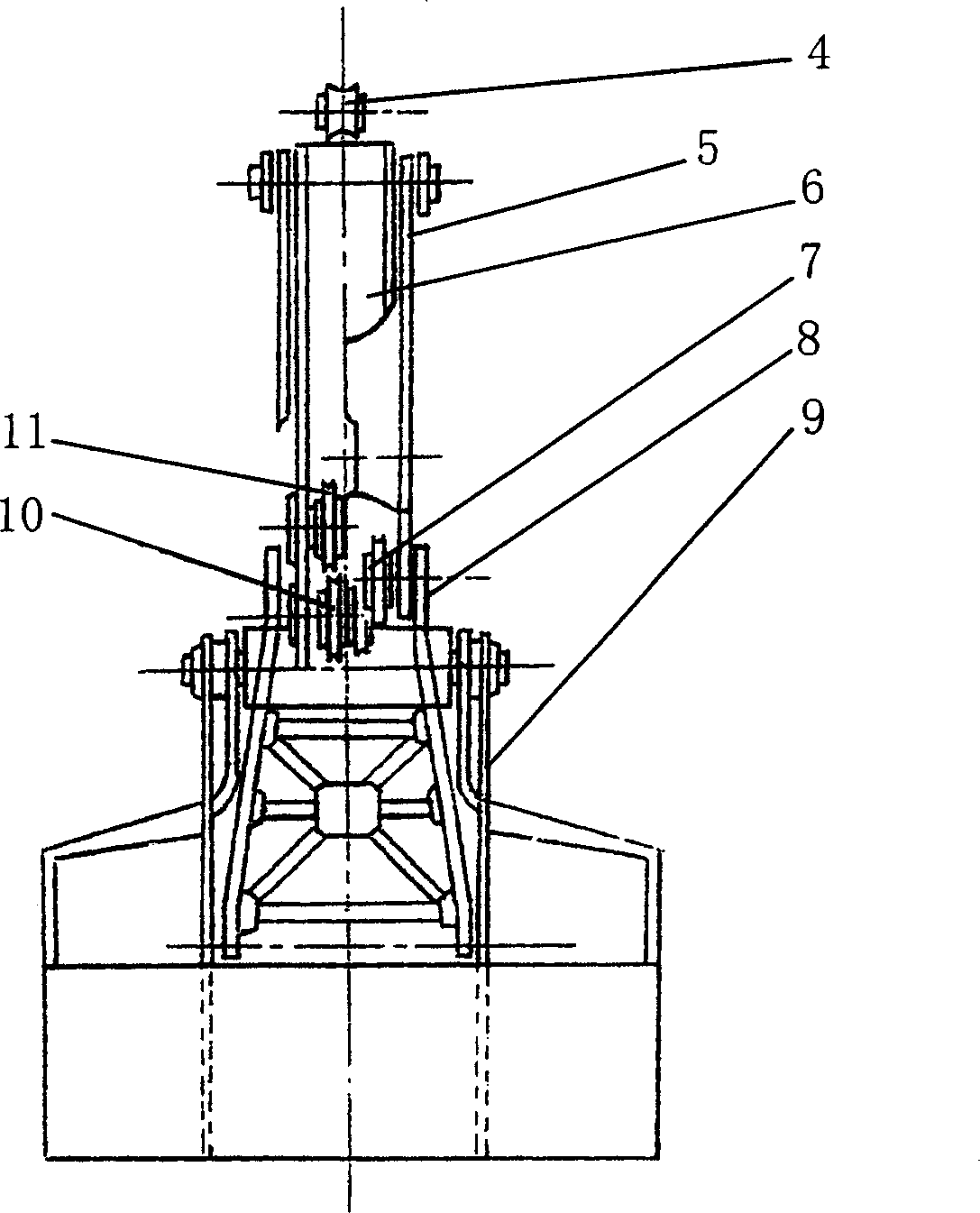

[0021] Such as Figure 1 to 4 Shown is a schematic structural diagram of a short strut grab bucket according to an embodiment of the present invention. It consists of two opening and closing ropes 1, two supporting ropes 2, a supporting rope frame 3, two rope pulleys 4, and two upper struts 5. , A middle beam 6, two strut pulley groups 7, two lower strut rods 8, two bucket jaws 9, a middle beam pulley group 10, a middle beam guide wheel group 11 and two connecting devices 12. The supporting rope 2 is connected to the supporting rope frame 3, the opening and closing rope 1 is wound on the center beam pulley block 10 through the rope pulley group 4, and the supporting rope frame 3 and the connecting device 12 arranged on the upper strut 5 are hinged to point F, The center beam guide wheel group 11 is arranged on the center beam 6. In addition, the upper strut 5 and the center beam 6 are hinged at point A, the upper strut 5 and the lower strut 8 are hinged at point B, the lower strut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com